Cleanroom Compatibility for Motion Control: A Practical Guide

By Dan Came, Product Manager

Published on May 27, 2025

Automated motion control is vital in cleanroom applications including semiconductor manufacturing, pharmaceutical research, and medical device assembly. It enhances precision, ensures consistent throughput, and reduces contamination from human sources. Moving parts can be a source of particle generation though, and it can be challenging to know the magnitude and nature of the contamination they introduce. Available cleanroom standards provide guidance on constructing and testing clean rooms themselves, but there is limited guidance on choosing equipment and the guidance for testing can be difficult to put into practice.

This guide aims to provide practical insights for selecting and implementing motion control equipment for cleanrooms. As there are a number of aspects of the design and operation of motion systems (from materials to drive mechanisms to speed) influencing particulate and chemical contamination, an understanding of these is essential. We will explore 7 key areas to focus on, discussing the nature of how each can introduce contamination and strategies to mitigate particle generation, before finally considering how you characterize and test particle generation in your system.

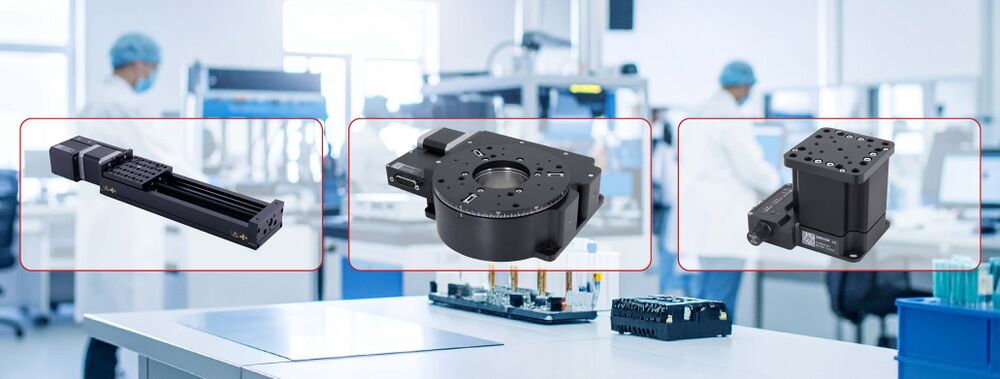

Bearings: Minimizing Particle Generation from Support Systems

Figure 1: Rolling bearings using hardened steel such as these used in Zaber stages offer excellent balance between particle generation and complexity.

Bearings are essential for guiding and supporting motion, but the contact and relative movement between their components can generate particulates.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

| Sliding Contact (Plain Bearings): Plain bearings involve direct sliding between surfaces. This action inherently leads to wear and particle shedding, especially as the bearing material breaks down over time. Higher friction also contributes to wear. | Avoid Plain Bearings: Due to their high wear and particle generation, plain bearings are generally unsuitable for most cleanroom applications. |

| Rolling Contact (Rolling Element Bearings): While affording lower particle generation than plain bearings, even rolling bearings (e.g., ball bearings, roller bearings, or cam followers) can generate particles through micro-wear of rolling elements and raceways, and from the cage material if present. | Prioritize Rolling Element Bearings: These are the preferred choice. Look for high-quality bearings with smooth raceways and durable materials. Recirculating ball bearings or crossed roller bearings are good options. |

| Lubricant Degradation/Dispersion: Lubricants used in bearings can degrade or be aerosolized, contributing to chemical or particulate contamination if not chosen carefully. Lubrication will be covered in more detail in its own section. | Consider Air Bearings for Ultra-Clean Applications: Air bearings eliminate mechanical contact, offering extremely low particle generation. However, they are more complex, costly, and require a clean, dry air supply. |

Other Mitigation Strategies and Design Choices:

- Select Suitable Materials: Ensure bearing components (balls, rollers, races, cages) are made from cleanroom-compatible materials that are resistant to wear and chemical degradation.

- Use Sealed or Shielded Bearings: These can help retain lubricant and prevent the ingress or egress of particles, though the seals themselves must be non-shedding.

Zaber's Approach:

Zaber predominantly uses rolling element bearings. For example, many of our screw-drive stages such as the LSM or LRM families employ recirculating ball bearings, and crossed roller bearings are used in our direct drive stages including in our LDM and LDA families. Both types of bearings offer excellent performance and minimal particle generation. Contact us for detailed information.

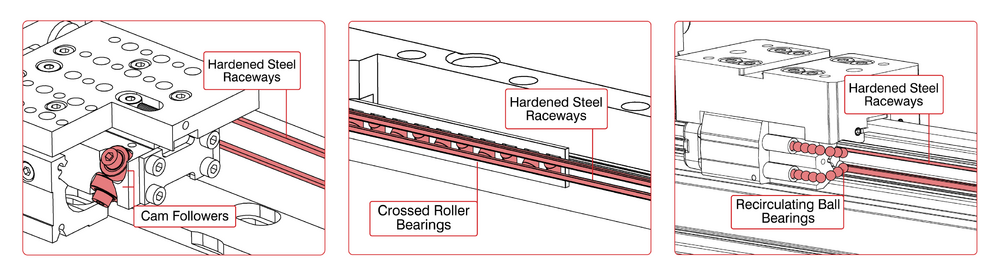

Drive Mechanisms: Selecting Low-Particle Actuation

Figure 2: Drive mechanisms such as these are necessary to move the motion system's payload, but their contribution to airborne particulate must be considered.

The drive mechanism translates power into motion. Depending on the type, this can involve components that rub, flex, or wear, each of which will release different particles.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

Screw Drives (Leadscrews, Ball Screws): These involve sliding and/or rolling contact between the screw and nut.

| Careful Selection of Screw Drives:

|

| Belt Drives: Belts, often made of rubber or composites, flex and wear during operation, shedding significant particulate matter. The belt rubbing against the pulley is a primary source. | Avoid Belt Drives: Generally not recommended for cleanrooms due to high particle shedding. |

| Piezoelectric Drives: These drives generate motion through the deformation of piezoelectric material. They typically have very low particle generation due to minimal moving parts in contact, but often offer limited travel range. Longer travel ‘inchworm’ versions incorporate sliding contact and generate particles. | Consider Piezoelectric Drives for Specific Applications: Suitable for short-travel, high-precision tasks. |

| Direct Drive Linear Motors: These use electromagnetic force to directly drive the payload. There is no mechanical contact between the motor's primary and secondary parts for drive transmission, making them an excellent option (though bearings are still needed for guidance). | Opt for Direct Drive Linear Motors for Lowest Drive-Related Particles: As there are no contacting drive mechanism parts, particle generation from the drive itself is completely eliminated. This is often the best choice for highly sensitive cleanroom applications. |

Zaber's Approach: Zaber offers various drive mechanisms. For example, our popular LSM family utilizes carefully selected screw drives (with features like a self-lubricating polyacetal nut on a PTFE-coated stainless steel leadscrew), and can be suitable for higher cleanroom classes without modification. To meet more strict requirements, enclosed drives like the ASR family or rotary drives are an option. Zaber’s LRU family uses ballscrews, while the LRQ and LRT families offer them as a standard option. To combine low particle generation with nanometer-scale movement, our LDM and LDA families feature direct drive linear motors to completely eliminate particle generation from the drive mechanism itself.

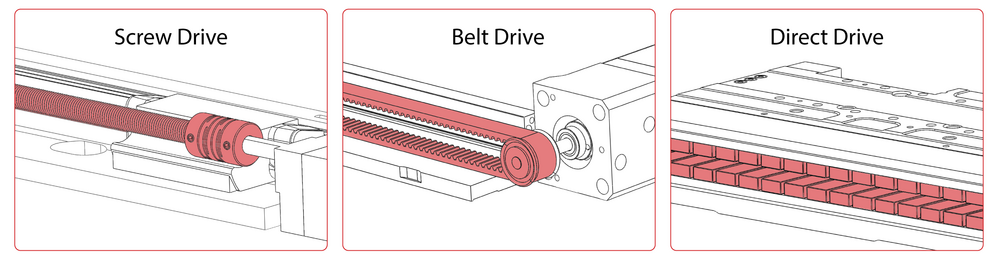

Material Selection and Enclosure Design: Building with Cleanliness in Mind

Figure 3: Incorporating uniform cleanable surfaces enables effective routine cleaning.

The materials used in equipment construction can directly shed particles or release chemical contaminants (outgassing), especially when subjected to movement, friction, or cleaning processes. Additionally, irregular enclosure shapes or protruding fasteners can interfere with essential routine cleaning.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

| Flexing and Abrasion of Plastics and Rubbers: Some plastics and rubbers can shed particles when flexed, rubbed, or exposed to UV light or chemicals (such as cleaning agents). | Select Cleanroom-Compatible Plastics: If plastics are necessary, choose types known for low particle shedding and low outgassing (e.g., PEEK, PTFE, some polycarbonates, acetal), especially for moving parts. |

| Oxidation and Corrosion of Metals: Untreated metals like aluminum or carbon steel can oxidize or corrode, forming particles (e.g., rust, aluminum oxide). These oxides can be abrasive and generate further particles if disturbed. | Use Metals with Stable Surfaces: Stainless steel is often preferred. If using aluminum, ensure it has a high-quality, durable surface treatment like anodization to prevent oxidation and particle shedding. |

| Outgassing: Some materials, especially certain plastics and adhesives, can release volatile organic compounds (VOCs) that can condense on surfaces and cause chemical contamination. | Verify Chemical Compatibility: Ensure all materials and surface treatments are compatible with cleanroom cleaning agents and process chemicals to prevent degradation, leaching, or particle generation. If adhesives are used, select low-outgassing, cleanroom-grade options. |

| Leaching/Shedding from Surface Treatments and Coatings: Unstable or poorly applied surface treatments or coatings can flake, leach chemicals, or react negatively with cleaning solvents. | Avoid Paints where Possible: Painted surfaces can chip or flake. If coatings are needed, prefer more robust options like anodizing or powder coating (if applied correctly, durable, and non-shedding). |

Zaber's Approach: Zaber devices generally use low reflectance black anodized aluminum for structural components. This provides a good balance of light weight, strength, and a stable, low-shedding surface. Contact us if using dye-free clear anodizing is a requirement in your system. Additionally, Zaber stages feature flat, uniform surfaces that are easy to wipe down and are designed with relatively few protruding fasteners or particle traps, facilitating easier cleaning.

Lubricants: Choosing Cleanroom-Compatible Formulas

Lubricants are a key component of motion control, and are vital for reducing friction, wear, noise, and heat in moving parts like bearings and drive screws. However, the wrong lubricant can outgas, shed particles, or support microbial growth.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

| Reaction with Process Chemicals: Some lubricants may react with chemicals used in the cleanroom or the manufacturing process, creating harmful byproducts or degrading the lubricant itself. | Select Cleanroom-Specific Lubricants: For cleaner classes of cleanrooms, use lubricants specifically formulated for cleanroom use. These typically have:

|

| Outgassing: Volatile components in the lubricant can evaporate and condense on sensitive surfaces, causing chemical contamination. | Prefer Synthetic Greases or Dry Lubricants: Many cleanroom lubricants are synthetic (e.g., perfluoropolyether - PFPE) as they offer better stability and lower outgassing than mineral oil-based lubricants. Dry film lubricants (e.g., MoS₂, PTFE coatings) can also be options where appropriate, eliminating liquid/grease concerns. |

| Particle Shedding/Aerosolization: Lubricants can break down over time or be aerosolized by fast movements, becoming airborne particles or droplets. | Consider Sealed Components: Sealed bearings or enclosed drive mechanisms can help retain lubricant and prevent its escape into the cleanroom environment. |

| Trapping and Re-releasing Particles: While lubricants can trap wear particles, if the lubricant migrates or degrades, these trapped particles can be released. | Apply Lubricant Sparingly and Correctly: Over-lubrication can lead to excess lubricant migrating and attracting contaminants. Follow manufacturer recommendations for application and check lubricant during routine maintenance. |

Zaber's Approach: Zaber carefully selects lubricants for its devices based on performance and compatibility. For applications requiring specific cleanroom-grade lubricants or where outgassing is a critical concern (e.g., vacuum applications), we can often accommodate these as part of a customization or provide guidance on appropriate choices.

Enclosures and Covers: Containing Potential Contaminants

Figure 4: Dust covers like these available on the LSQ family can mitigate particle generation when specified correctly.

Covers and full enclosures around motion systems can help contain particles generated by internal mechanisms (bearings, drives) and prevent them from entering the cleanroom atmosphere. They can also protect mechanisms from external contaminants or accidental operator contact that might spread lubricants.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

| Particle Generation from Contacting/Sliding Covers: Covers that rub or slide against other parts of the equipment during motion (e.g., some types of bellows or flexible covers) can themselves become a source of particles. | Prefer Non-Contacting or Rigid Covers: Rigid, non-contacting covers are generally best. If flexible covers (like bellows) are needed, ensure they are made from low-shedding, durable materials specifically designed for cleanroom or dynamic applications. |

| Trapping and Releasing Contaminants: Poorly sealed covers might trap particles and then release them if disturbed or during maintenance. | Proper Sealing: If the goal is full containment, ensure covers are well-sealed using cleanroom-compatible gaskets or seals. However, consider pressure differentials if fully sealed. |

Other Mitigation Strategies and Design Choices:

- Material Selection for Covers: Use cleanroom-compatible, non-shedding materials for covers (e.g., anodized aluminum, stainless steel, certain stable plastics).

- Design for Cleanability: Covers should be easy to clean and not have crevices where particles can accumulate.

- Consider Vented Enclosures with Local Extraction: In some cases, an enclosure can be combined with a small, dedicated vacuum or extraction system to actively remove particles from the vicinity of the motion equipment.

Zaber's Approach:

Many Zaber products like the LSM and LSQ families offer rigid dust covers designed from appropriate materials to minimize generation of particles while containing those from the drive mechanism. Custom enclosures can also be discussed for specific application needs.

Cables and Cable Management: Preventing Particle Generation from Flexing Components

Figure 5: Flexible enclosed cable guides like this one can be a useful custom option to itself generate fewer particles and also contain any particles generated by the cables inside.

Automated motion systems require power and data connections. The cables for these may need to flex and move with the equipment. The cables themselves and the systems used to guide them (cable carriers/chains, guides) can generate particles through friction and wear.

| CONTAMINATION MECHANISMS | MITIGATION STRATEGIES & DESIGN CHOICES |

|---|---|

Cable Insulation and Jacketing

|

Consider Using Cleanroom-Rated Cables: For stricter classes of cleanrooms, consider using cables specifically designed for dynamic cleanroom applications. These often feature:

|

| Cable Carrier Wear: Traditional plastic-on-plastic cable carriers generate particles as their links articulate and rub. | Opt for Low-Particle Cable Management:

|

Other Mitigation Strategies and Design Choices:

- Proper Cable Routing and Strain Relief: Ensure cables are routed to minimize stress, twisting, and sharp bends, which can accelerate wear.

Zaber's Approach:

Our standard cables can often be used in higher classed cleanrooms. To meet stricter requirements, reach out to us to discuss specialized cleanroom cable and carrier options.

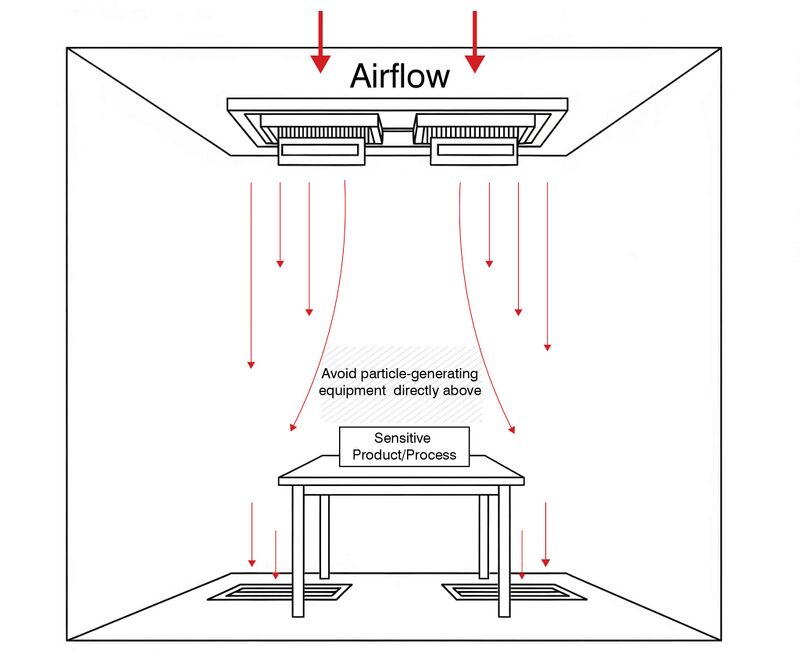

Optimizing Operations for Cleanliness

Figure 6: In addition to design considerations, operational considerations like position in the cleanroom and operating parameters can also significantly affect particulate effects.

Maintaining cleanroom integrity isn't just about equipment selection; it's also about how that equipment is installed and operated.

Equipment Placement and Airflow:

- Understanding Airflow: Cleanrooms typically use ceiling to floor airflow which is often laminar but may be turbulent. Be aware of your cleanroom's specific airflow patterns.

- Strategic Positioning: Place particle-generating equipment downstream (in terms of airflow) from sensitive products or processes. Avoid positioning potential sources directly above critical items. If unavoidable, consider physical shielding. Automation itself can help by removing operators (a major particle source) from positions near or above critical workpieces.

Movement Parameters (Speed, Acceleration, Load):

- Minimize When Possible: Operate equipment at the lowest speeds and accelerations that still meet your process requirements.

- Mechanism: Higher speeds can increase wear on bearings and drive mechanisms, potentially aerosolize lubricants, generate heat (which can accelerate material degradation or lubricant outgassing), and cause vibrations that lead to more particles. Fast movements also disturb the air, potentially making settled particles airborne even if they don't originate from the device itself.

- Respect Load Limits (Pressure/Velocity Limits): Stay within the rated maximum continuous thrust limits and overall load capacity for your device, and limit the duty-cycle.

- Mechanism: Overloading increases temperature, which causes accelerated wear and particle generation.

- Mounting Orientation: Be aware that mounting orientation (horizontal vs. vertical) can affect loads on bearings and drive systems, potentially influencing particle generation differently.

Zaber's Approach:

We offer a variety of standard mounting brackets, plates, and accessories that can assist in optimal positioning and shielding. Custom designs are also possible. Our device specifications are published to our website to enable operators to plan around operational speed and payload limits.

Verifying Cleanroom Compatibility: Testing and Validation Approaches

Figure 6: Particle counters like this one used by Zaber can provide particle data for equipment, but interpretation of the results can be nuanced.

While the cleanroom compatibility of a motion control device can often be reliably inferred from its design, constituent materials, and intended operational parameters, a precise quantitative prediction of particulate shedding remains challenging due to numerous contributing variables. Definitive confirmation of suitability and subsequent classification of the cleanroom environment will rely on empirical testing of the fully populated cleanroom in operation.

The Importance of Empirical Testing

- Inferring compatibility solely from design and material specifications has limitations, as complex interactions and operational dynamics can influence actual particulate generation.

- Empirical testing provides the most definitive confirmation of a motion control system's performance within the intended cleanroom environment.

Key Cleanroom Testing Standards

- Overall Cleanroom Qualification (ISO 14644-1):

- This standard defines international cleanroom classifications based on acceptable airborne particulate loads.

- It mandates operational state testing of the entire cleanroom to verify compliance.

- (Note: The US FED STD 209E classifications are still sometimes used despite being officially withdrawn in 2001).

- Equipment-Specific Testing (ISO 14644-14):

- Titled "Assessment of suitability for use of equipment and materials by airborne particle concentration," this standard provides guidance for testing individual equipment and was used to design Zaber’s internal particle characterization test program.

- Although this testing is not often performed by individual cleanroom operators, it can be useful when a high degree of assurance regarding equipment compatibility is required prior to installation, especially if the cleanroom's particulate budget is constrained.

Practicalities of Equipment Testing (ISO 14644-14)

- Complexity and Test Definition:

- The execution of equipment-specific tests can be complex, as each cleanroom environment and application presents unique conditions.

- The standard mandates that critical test parameters be rigorously defined and controlled, including:

- Test environment airflow characteristics.

- Equipment operational speeds and modes.

- Ambient temperature and humidity.

- Measurement probe position relative to locations of high particle concentration (HPCs).

- Common Challenges:

- Test data will generally exhibit high variability. To achieve statistical confidence the ISO 14644-14 standard mandates a minimum of 100 samples per measurement location, which can be time-consuming and costly.

- Alternative Approaches:

- Due to these complexities and costs, many cleanroom operators elect to omit separate, isolated equipment testing. Instead, they specify equipment expected to be compatible with their cleanroom based on the characteristics discussed in this article, and rely on the results from the comprehensive cleanroom qualification (encompassing as-built, at-rest, and operational states) as a final check of acceptable overall particulate loads.

Holistic Validation Considerations

- Beyond standardized particle counting, a comprehensive validation approach for new equipment should consider:

- All Potential Contaminants: Address not only particles but also potential chemical outgassing or, in life science applications, bioburden and endotoxin contributions.

- Equipment Location and Process Proximity: Evaluate the placement of the motion system relative to critical products or sensitive process zones.

- Usage Profiles: Consider both typical and extreme equipment usage patterns (e.g., duty cycles, speeds, loads) that might affect contaminant generation.

- Cleaning and Sterilization Compatibility: Ensure the equipment's materials and design are compatible with established facility cleaning, disinfection, and (if applicable) sterilization procedures.

Zaber's Approach: We leverage our experience with our own cleanroom as well as that of our past customers to provide useful heuristics for compatibility. Additionally, a test program for particle generation characterization of our product range is currently underway. Contact us for details.

Conclusion

The commissioning and operation of a cleanroom involves careful planning and consideration, and the integration of motion control equipment is no exception. Fortunately, the benefits derived from well-implemented automation—including enhanced throughput, improved process consistency, and a reduction in human-generated contamination make that effort worthwhile. By systematically evaluating the design of motion systems, selecting materials, and defining operational parameters in accordance with their specific cleanroom requirements, organizations can successfully incorporate automation while maintaining strong confidence in meeting necessary cleanliness standards. Leveraging motion control manufacturers’ expertise can also expedite the process.

While Zaber’s standard solutions align with many of the best practices for automation in cleanroom, there are also a number of optimizations that are available as customizations upon request. If you have questions regarding the optimal motion control solutions for your cleanroom class and motion requirements, or if you need to discuss specialized considerations such as electrical grounding, bioburden, chemical compatibility, or vacuum compatibility, please contact us to speak with one of Zaber's knowledgeable applications specialists.