Direct Drive Motor Overview and Selection Process

By Albert David, Applications Engineering Team

Published on Aug. 10, 2018

Introduction

Direct drive motors are a motion technology that moves the payload directly without the use of mechanical drive mechanisms like gears, screws or belts. They can be used for both linear and rotary motion. Direct drive rotary motors couple the payload directly to the rotor, eliminating any play or backlash in the motion. Direct drive linear motors, take the stator and rotor concept of a rotary motor and unroll it into a linear configuration. While direct drive is not a new technology, advances in the past few decades – including increased efficiency, greater power density, and more advanced controls – have made this drive type ideal for high precision motion control solutions. Growing popularity and usage in applications requiring precision motion control have also sparked a reduction in the cost of the technology and made direct drive motors a more economical option for many applications.

As the technology has developed, the number of options and configurations have also increased, with each type of direct drive motor featuring a completely different set of performance characteristics. While this has widened the number of requirements that direct drive motors can meet, it can also make it more challenging to specify the most suitable product.

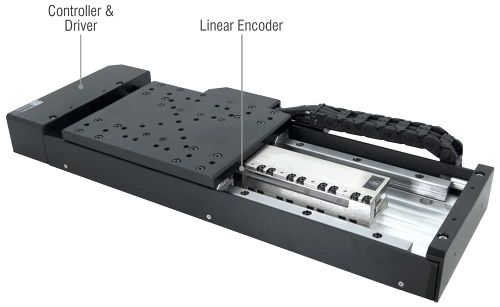

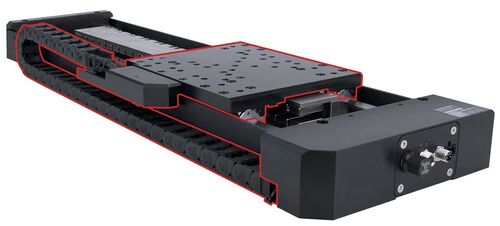

To help make this process simpler, we'll start by explaining the mechanics of a direct drive motor and contrast it with a more traditional indirect drive system. With this foundation, we'll look at different types of direct drive motors, highlighting their benefits, to help identify the kinds of applications for which each is suitable. Finally, we'll cover some of the unique benefits provided by Zaber's direct drive motor devices. Figure 1 is an example of a Zaber direct drive linear motor stage with an integrated controller and driver.

Direct Drive vs Indirect Drive

When a standard rotary motor is used in a motion control device, typically that rotation is not the kind of motion that's actually required; any or all of the direction, speed, and force may need to be different. In order to redirect the motion, mechanical parts such as gears, lead screws or ball screws, couplers, belts, and pulleys are used. Each of these components introduce friction or inaccuracy into the system, reducing the efficiency and limiting the precision. We can call these 'indirect drive' systems. These systems may use position feedback to improve accuracy but can use a variety of different encoders and motor types and can be run without position feedback.

In contrast, devices that use direct drive motors do not have a mechanical conversion between the motor force and the required travel. This ensures the maximum efficiency and accuracy but also means that the right motor with proper specifications must be chosen as there is no mechanism to amplify the force or extend the travel range of the motor. Additionally, while direct drive motors are capable of creating precise and accurate motion, they require equally precise position feedback (using a direct encoder) and an advanced driver with a servo control loop to get the most performance out of the drive.

By eliminating the mechanical conversion components in linear or rotary stages, direct drive devices are typically able to offer:

- Smaller minimum incremental move

- Higher accelerations and maximum speeds due to higher efficiency

- Zero backlash

- Higher precision

- Longer lifetime due to zero friction/contact in the drive mechanism

While these characteristics make direct drive devices excellent for many positioning and motion control applications, there are some considerations where an indirect drive option may be more suitable because direct drive devices:

- Lack "power off" stability

- Can generate significant heat at the load and require temperature management (such as limiting duty cycle)

- Have a higher price

- May be larger than an indirect drive device with similar thrust

Direct Drive Motor Overview

To explain direct drive motors, first let's briefly describe motors in general. Electric motors create motion by generating an electromagnetic field that interacts with another magnetic field, typically generated by a permanent magnet. The electromagnetic field is varied by controlling current in the coils (also called windings) in order to control the movement.

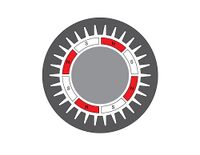

The rotating part of the motor is called the 'rotor', and the stationary part is the 'stator'. Zaber uses brushless motors, where the permanent magnet is part of the rotor, and the windings make up the stator, as seen in Figure 2a. The permanent magnet rotor may have as few as two poles (i.e. North and South), but often has some multiple of the two. As the current to the coils is varied, the magnetic field cycles through which pole is attracted, causing the rotation.

Direct drive rotary motors are fundamentally the same as any brushless motor, where the stator is stationary and the rotor containing permanent magnets moves due to electromagnetic fields caused by the stator. However, what makes it “direct drive” is that the rotor is directly coupled to the payload, as opposed to a worm gear or belt drive on an indirect drive stage.

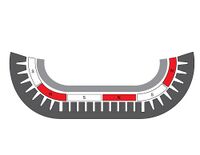

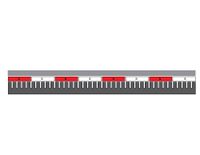

On a direct drive linear motor, both the stator and rotor are in-line with each other. Picture the motor being un-rolled, as seen in Figure 2b, resulting in a flat, direct drive linear motor, seen in Figure 2c. Exactly how they are laid out, and which of the components move versus which are stationary, determines the type of direct drive linear motor. The coil that current is running through is typically called the 'forcer' for direct drive linear motors. Rather than producing a torque, a linear force along the stage's travel length is generated as the current is varied to the forcer.

Figure 2a: Typical rotary motor. |

Figure 2b: "Un-rolling" a rotary motor. |

Figure 2c: Direct drive linear motor. |

Different Kinds of Direct Drive Motors

Different types of direct drive motors exist because each one compromises one aspect of performance in order to excel in another. There are four main attributes in which there is a trade-off in performance: flux density, flux leakage, moving mass, and cogging torque.

Flux Density is the magnitude of the magnetic field that can be generated within a certain space. High flux density devices provide superior force or allow a similar force in a more compact size.

Flux Leakage is an indicator of how well the electrical field is contained within the motor. Low flux leakage is typically preferable in order to prevent the magnetic field from affecting other components of the system. Flux leakage also indicates lower electrical efficiency of the motor.

Moving Mass is the mass of the moving components of the motor. Higher moving mass means lower acceleration for two motors that each have the same force output.

Cogging Force (also known as detent force) is present in any direct drive motor that uses iron and is the attraction of the iron to the permanent magnets. When the motor is powered and moving, it results in a cyclical force ripple over the range of travel.

In addition to these four main attributes, size and cost also vary between the different solutions available.

It is challenging to cover every type or configuration of direct drive motor in a short article, so the following section will focus on three distinguishing traits that are relevant for high-accuracy positioning systems: (1) flat vs U-shaped motor tracks, (2) moving coil vs moving magnet tracks, and (3) iron-core vs ironless forcers. Keep in mind that most, but not all, direct drive motors consist of the same main components: magnet tracks lined with permanent magnets, a forcer, and a high resolution direct encoder.

Flat vs U-shaped

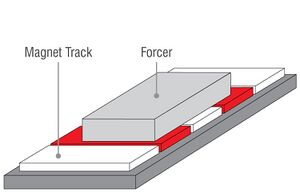

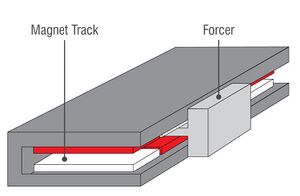

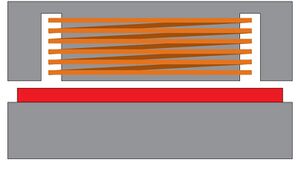

Flat direct drive motors, as shown in Figure 3a, have a single magnet track. They generally have a lower profile and reduced cost, since they only require one magnet track. Flat direct drive motors generally have higher flux leakage and lower force to weight ratio. U-shaped motors, as shown in Figure 3b, have an additional magnet track, opposite the first magnet track, with the forcer moving in-between the tracks.

Figure 3a: Flat direct drive motor. |

Figure 3b: U-shaped direct drive motor. |

Moving Coil vs Moving Magnet Track

In direct drive rotary motors, the windings are typically the stator because if they were part of the moving rotor the wires to it would wind up. In direct drive linear motors, this is not a consideration; the travel is limited and linear so the wires to the forcer cannot wind up. While the forcer can be the stationary 'stator', direct drive linear motors can also be set up where the forcer is moving. Typically these two kinds of systems are called either moving coil or moving magnet track motors.

Moving coil direct drive linear motors, as shown in Figure 4a, are typically used in longer travel devices in order to keep the moving mass low. The travel of any direct drive linear motor stage is limited to the length of its magnet track. For short travel stages the magnet track is also short, which keeps it relatively light and suitable for a moving magnet track stage. For long travel stages, the magnet track is long and becomes very heavy, and it makes more sense to move the coil. A downside of the moving coil direct drive linear motor is that the cables to the forcer are also always moving, so cable management is required. In general, moving coil direct drive linear motors have lower moving mass for greater acceleration.

For requirements with limited travel range, moving magnet track systems, as shown in Figure 4b, may be better as they are able to achieve higher precision. This is possible because the moving portion of the motor is electrically and thermally uncoupled, meaning it is thermally more stable and has less electrical noise. Also the stationary forcer, which heats up when current is running through it, is mounted to the base of the system, which acts as a heat sink and ensures the entire system has better thermal stability.

Iron-core vs Ironless

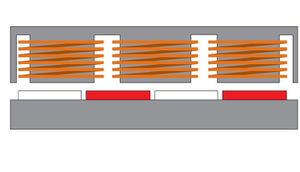

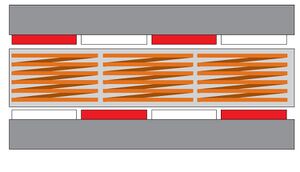

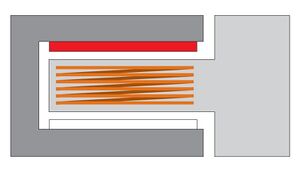

A typical iron-core motor has an iron backplate mounted to the forcer, and the coils are wound around iron laminations, as shown in Figure 5a and Figure 5b. Adding iron to the forcer reduces flux leakage and increases the flux density and the force output. The addition of iron to the motors also introduces cogging forces, as well as load to the bearings due to the attractive forces to the permanent magnets. A variation of the iron-core configuration is called slotless iron-core, where the coils of the forcer are not wound around iron laminations. This helps mitigate the cogging forces but also reduces the flux density. Motors without an iron-core are called ironless direct drive motors, shown in Figure 5c and Figure 5d, and can be used when velocity stability is more important than high force. Ironless direct drive motors also allow for a more consistent force distribution over full travel. For moving coil, direct drive motors, the iron core can be heavy, so ironless forcers offer lower moving mass.

Figure 5a: Side view of a flat, iron core direct drive motor. |

Figure 5b: End view of a flat, iron core direct drive motor. |

Figure 5c: Side view of a U-shaped direct drive motor. |

Figure 5d: End view of a U-shaped direct drive motor. |

Why Choose Zaber?

Zaber's direct drive motor devices use configurations that offer excellent performance. They combine the high accuracy, precision, speed, and acceleration that is required for many applications. Specifically, our devices:

- Use U-shaped motor designs for low flux leakage and increased flux density.

- Have ironless direct drive motors which are lighter and offer better precision and velocity stability during motion.

- Are available in moving coil or moving magnet track configurations.

- Have a built-in controller and driver option available for simplified cabling and easy setup.

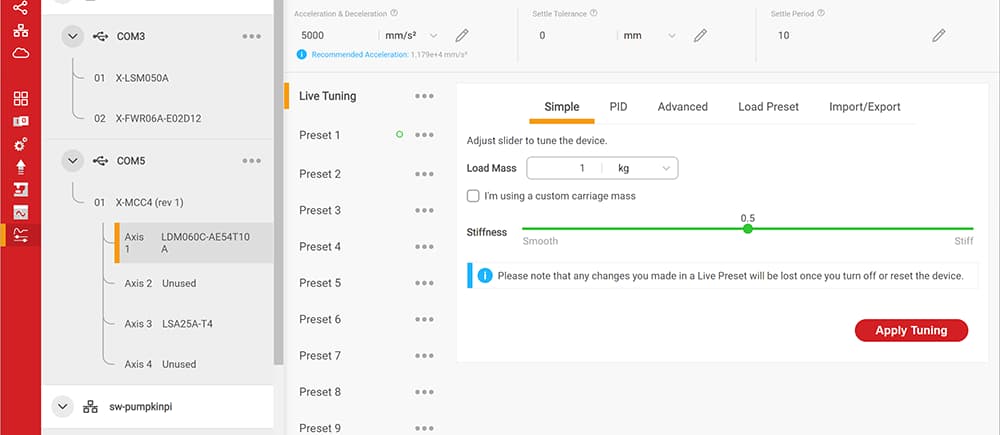

- Have an option without built-in controller, which works with the multi-axis X-MCC series controllers.

- Are shipped pre-tuned, with free software to quickly and easily adjust tuning parameters.

At Zaber Technologies our mission statement is to Simplify Motion Control. As such, Zaber is the first company to build the controller and driver into the device. Having an integrated controller eliminates the need to find a controller that's compatible with the type of motor; it reduces cabling and allows the device to be shipped pre-tuned. Zaber's direct drive products can also daisy-chain data and power to multiple devices, further minimizing connections and simplifying control.

Another main benefit of these devices is that for most direct drive devices, once the controller is connected, the servo control loop still needs to be tuned. This can be a complicated process requiring a reasonably in-depth understanding of feedback loops. Using Zaber devices simplifies this process, as the controller is pre-set with most of the system parameters. Zaber also offers a friendly tuning interface, shown in Figure 6, to get the stages running quickly and easily without requiring any background in servo control; only the mass of the load is needed. For those with more familiarity and comfort with tuning servo controllers, a more advanced interface with many control options is available. In addition, we have an Oscilloscope app as shown in Figure 7, which can help visualize the servo control settings defined in the Servo Tuner app.

Conclusion

The options for precision positioning devices may seem daunting, but Zaber's Applications Engineering Team is here to help you select the best product for your set-up. With our wide range of standard and customized stepper and direct drive devices, we can meet the requirements of most systems, and if you need products outside our range, we are happy to make some recommendations for you.