Types of Bearings in Linear Motion Systems

By Graham Davison, Mechanical Engineering Team

Published on Apr. 17, 2023

Linear bearings are used in many applications that require consistent and precise motion along a defined path. Many different linear bearing designs exist, suited for operation in a variety of applications and environments. The purpose of a linear bearing is to provide low-friction motion in one direction, while resisting loads and moments applied in all other directions.

We will be showing the most common types of linear bearings and how the design and implementation of these bearings affects the performance of linear motion stages.

Types of Linear Bearings

Zaber offers many different styles and sizes of linear translation stages, designed to excel in particular applications. These linear stages use many different types of linear bearings. Each bearing or guide type offers unique benefits in terms of cost, lifetime, accuracy, load capacity, friction, maintenance and stiffness among other things. Some examples of these bearing technologies are:

- Track Rollers or Cam Followers

- Recirculating Ball Bearings

- Crossed Roller Bearing Guides

Zaber does not sell products with the following types of bearings, but they are available on the market for other applications:

- Recirculating Roller Bearings

- Flexures

- Air Bearings

- Hydrostatic Bearings

- Dovetail Slides (also known as plain bearings)

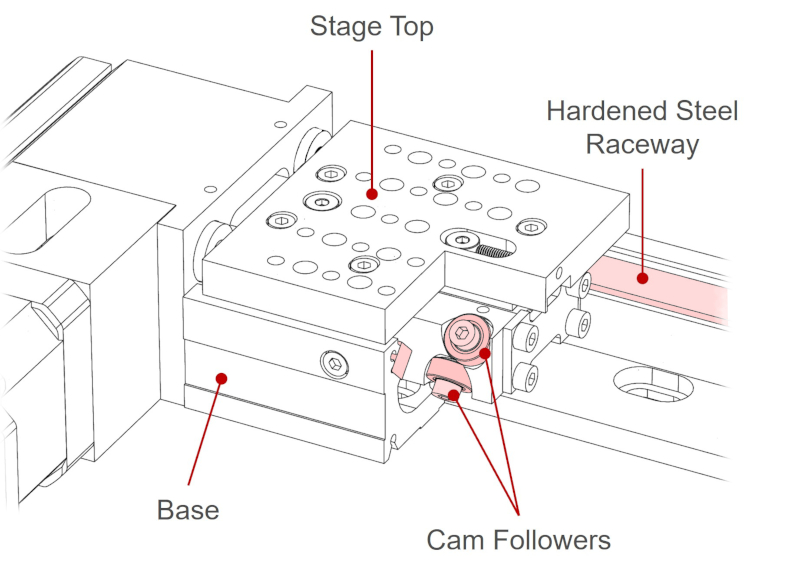

Track Rollers

Track rollers, also known as cam followers, usually consist of a threaded stud and circular bearing element. Multiple cam followers need to be used in the carriage of linear motion systems to constrain the stage top to a single degree of freedom. The system shown below uses eight cam followers on a square profile track. In this case the track is a hardened steel raceway which is integrated into the aluminum base. This offers improved bearing lifetime while still being cost effective, as the steel raceway is more wear resistant and can support higher loads than a simple aluminum base.

|

Pros:

|

Cons:

|

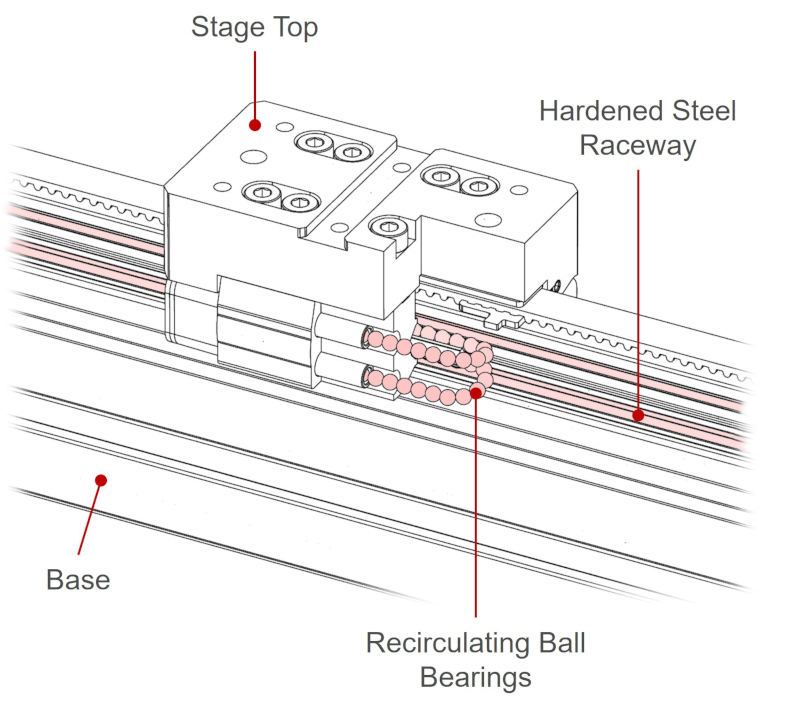

Recirculating Ball Bearings

Recirculating bearings use many balls in a closed circuit that continually recirculate as the bearing translates. A linear bearing usually has two or four circuits of balls to fully constrain motion and support loads from all directions. Many of Zaber’s linear stages incorporate recirculating ball bearings due to their excellent price-performance ratio. Linear systems with recirculating ball bearings have excellent lifetime, load capacity, and stiffness. The rolling elements also provide much lower friction than plain bearing systems, enabling high speeds, as well as the use of smaller motors and drive mechanics.

Zaber’s linear recirculating bearings commonly use a two-part design consisting of an aluminum base with hardened steel raceways to reduce overall weight, as aluminum has an excellent stiffness-to-weight ratio. Hardened steel raceways offer smooth motion with long lifetime even when supporting large centered loads and unbalanced moment loads. Zaber’s LRM Family uses a full steel construction design with recirculating ball bearings for the best stiffness and thermal stability. These systems can easily handle loads or moments from any direction, without much change to the motion accuracy or friction.

|

Pros:

|

Cons:

|

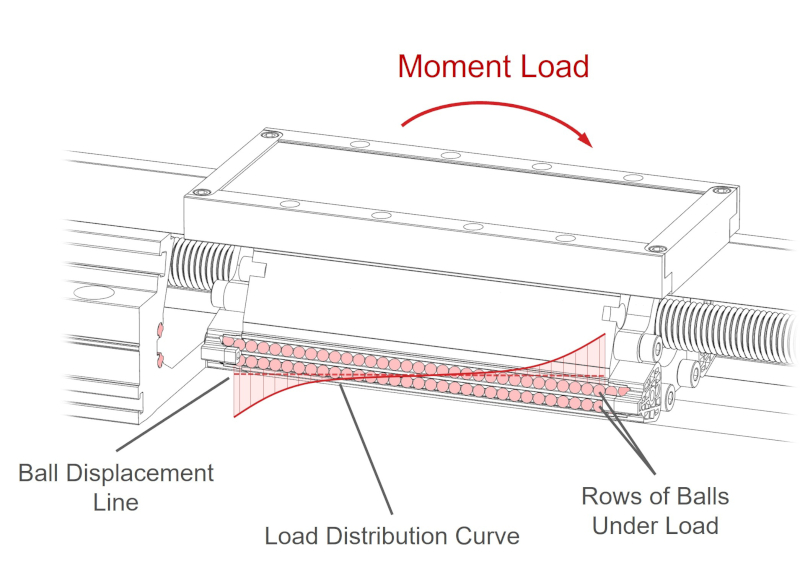

The diagram below shows the reaction forces on each ball from a moment load applied in a recirculating ball bearing system.

We can see that there are more load bearing elements in contact than in a cam follower system, meaning that greater loads with less deflection can be supported in a similarly sized linear stage. This style of linear bearing is also excellent at handling combined loads, which are a combination of lateral (side), vertical (tension/compression) and moment loads.

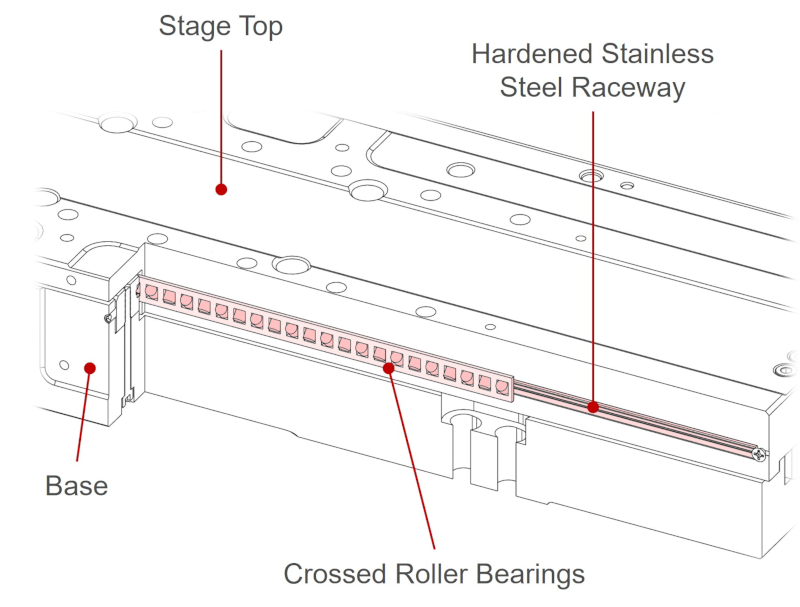

Crossed Roller Bearing Guides

Crossed roller bearing guides offer the utmost performance for rolling element bearings. These systems do not rely on recirculation of the rollers, which means that all of the cylindrical rollers stay in contact with the linear ways at all times. This results in very smooth, nearly frictionless motion with minimal bearing induced vibrations, extremely low motion error and high stiffness. Every other roller is rotated 90° to allow the bearing system to handle loads from all directions. These systems can be packaged into a very small volume while maintaining high stiffness and load capacity.

Zaber’s highest precision linear motor stages like the LDM Family, LDA Family and ADR Microscope Stage use crossed roller bearings. Stepper motor driven stages can benefit from crossed roller bearings too, such as the ASR Microscope Stages and the vertical VSR Family.

One small downside with crossed roller bearings is that these systems have a limited travel range compared to recirculating guides since the length of the moving stage top controls the device’s maximum linear travel range.

|

Pros:

|

Cons:

|

Zaber offers many sizes of linear stages, with most utilizing recirculating ball bearings due to their outstanding performance. If you have questions about which stage is the best solution for your application, contact us to speak with one of Zaber's knowledgeable applications specialists. To view Zaber’s full lineup of stages, visit the linear stage or vertical stage product pages.