LC40-GANTRIES Series User's Manual

LC40 - Versatile T-Slot Systems

Disclaimer

Zaber’s products are not intended for use in any critical medical, aviation, or military applications or situations where a product's use or failure could cause personal injury, death, or damage to property. Zaber disclaims any warranty of fitness for a particular purpose. The user of this product agrees to Zaber's general terms and conditions of sale.

Precautions

Collision Hazard! Zaber gantries contain motion products with significant thrust and load capacities. Take caution to prevent collisions with operators, work surfaces, and sensitive equipment.

Collision Hazard! Zaber gantries contain motion products with significant thrust and load capacities. Take caution to prevent collisions with operators, work surfaces, and sensitive equipment.

Heavy! Completely assembled gantry products, partial assemblies, and some stage products can be very heavy. Exercise caution when lifting/moving larger assemblies and products. Loosely fasten risers and stage axes as soon as they are placed during assembly to prevent tipping and falling hazards.

Heavy! Completely assembled gantry products, partial assemblies, and some stage products can be very heavy. Exercise caution when lifting/moving larger assemblies and products. Loosely fasten risers and stage axes as soon as they are placed during assembly to prevent tipping and falling hazards.

Important: Gantry products must be properly assembled and aligned to function optimally. Follow assembly instructions closely and contact Zaber Customer Support for help at any time if needed.

Important: Gantry products must be properly assembled and aligned to function optimally. Follow assembly instructions closely and contact Zaber Customer Support for help at any time if needed.

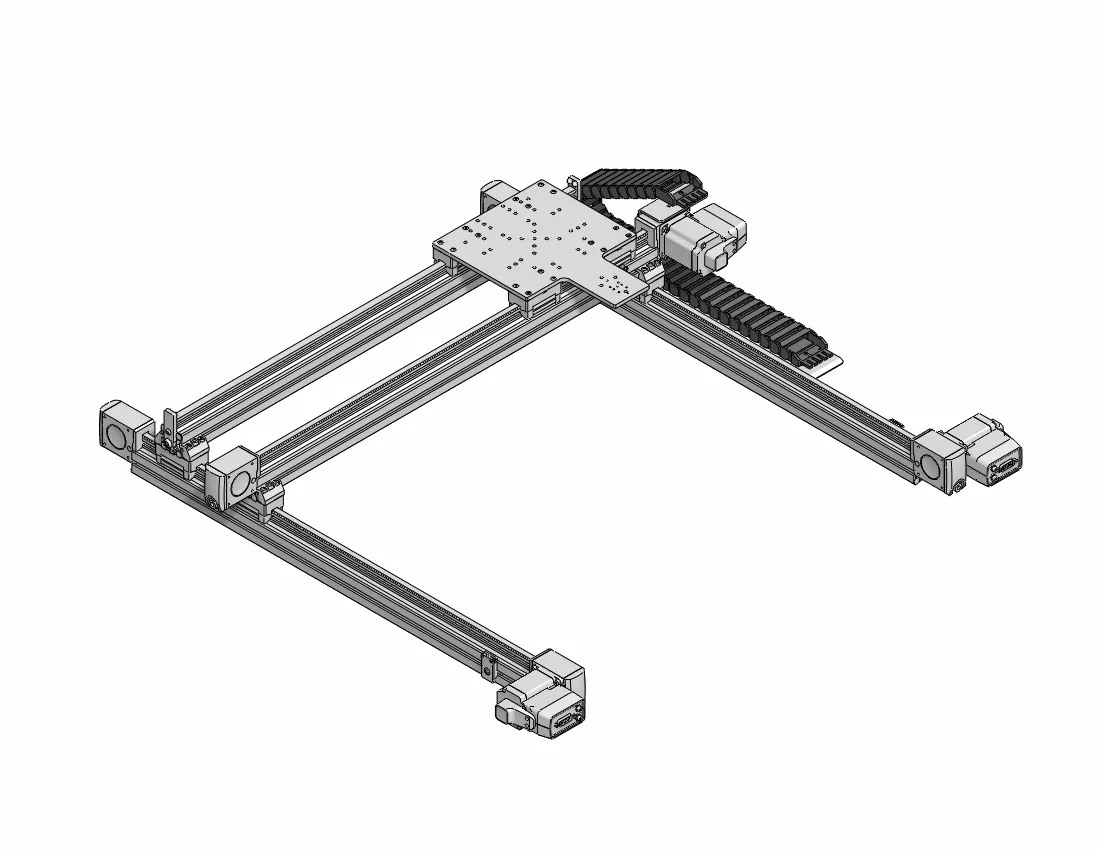

Product Overview

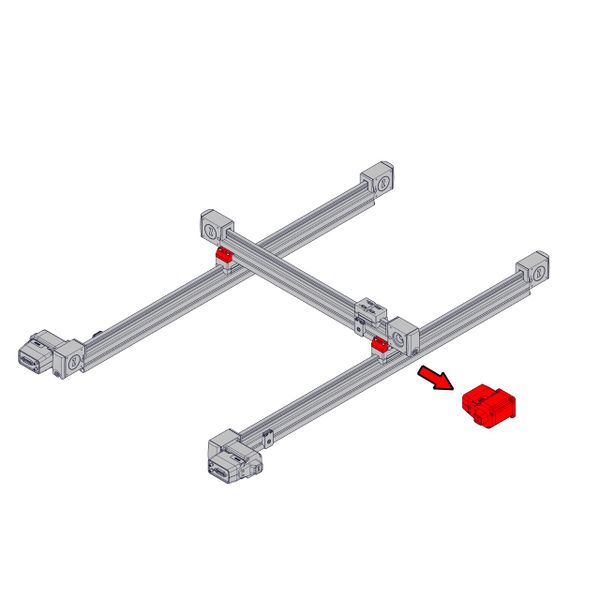

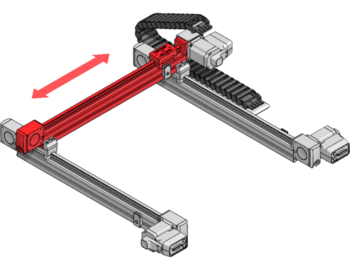

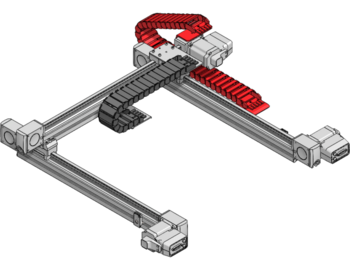

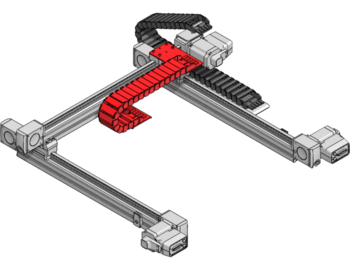

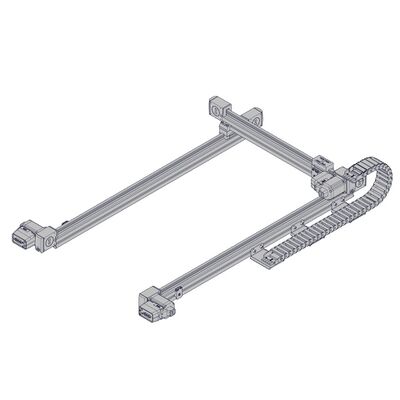

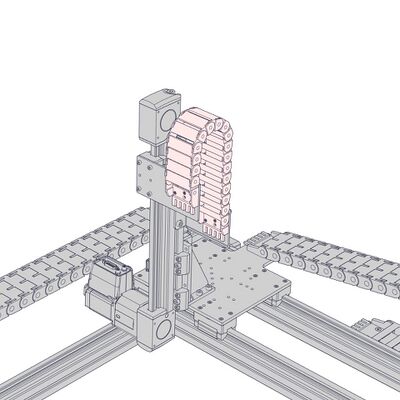

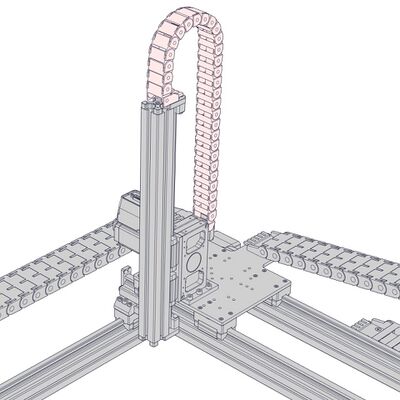

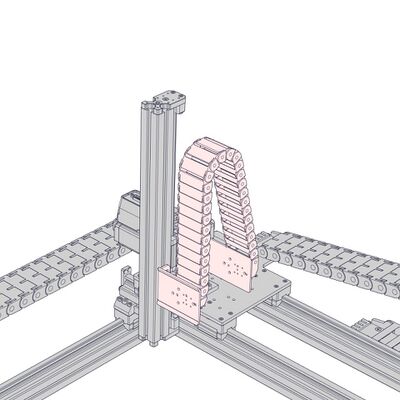

The following documentation uses specific terminology to refer to parts of the gantry product, outlined in the diagrams below:

| X-Axis Axes 1 and 2 |

Y-Axis | Z-Axis |

|

|

|

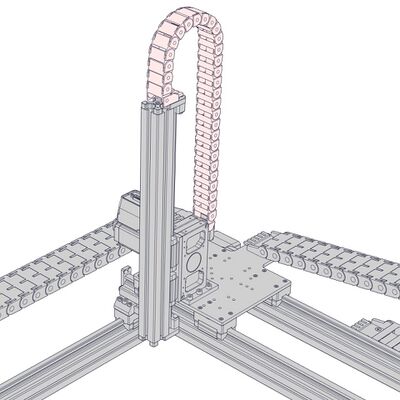

| X-Axis Cable Guide for Y-axis Cables and Optional Z/Theta/End Effector Cables |

Y-Axis Cable Guide for Z/Theta/End Effector Cables |

Z-Axis Cable Guide for Theta/End Effector Cables |

|

|

|

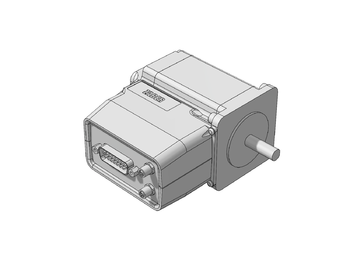

| Motors Intended for External Controllers for use with X-MCC controller and MC10T3 cables |

Motors with Integrated Controllers for use with X-DC cables |

|

|

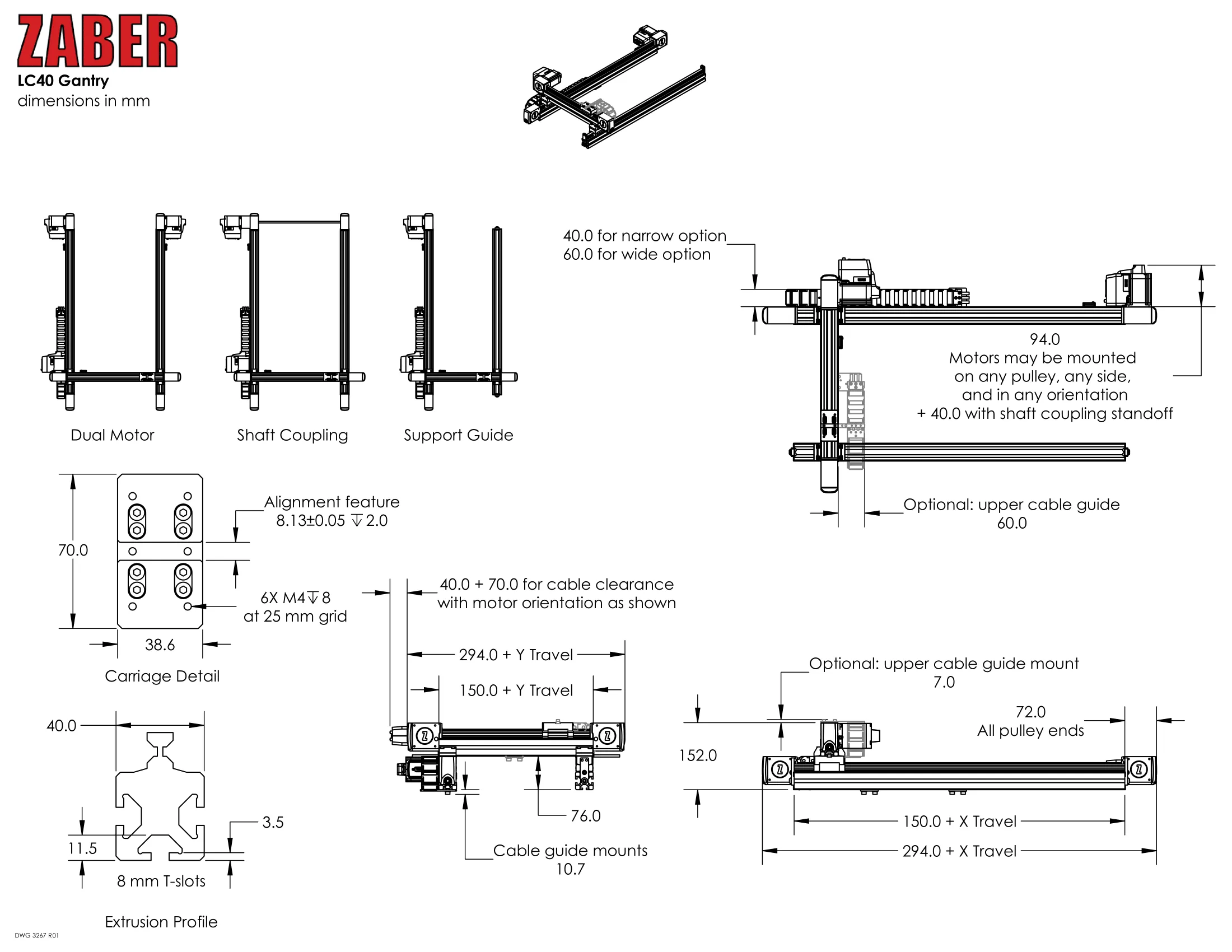

See Product Drawings for more information.

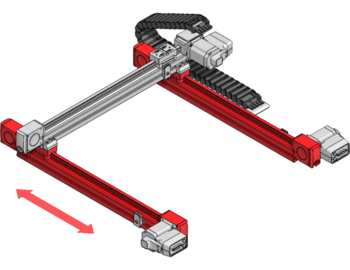

Cable Lengths

For LC40 gantries with an external controller, the X-axis side with a cable guide should be paired with the shortest MC10T3 motor cable. The Y-axis cable should be at least 670 mm longer than the expected X-axis travel.

For LC40 gantries with integrated controllers, the Y-axis motor & controller will be daisy chained to the X-axis motor & controller by an X-DC power and data cable. This cable should be at least 400 mm longer than the expected X-axis travel. The X-axis motor & controller may be connected directly to a computer, or extended with an additional X-DC cable.

Important: We recommend laying out all of the cabling and components before assembly to ensure there is an appropriate length of cable for each axis.

Important: We recommend laying out all of the cabling and components before assembly to ensure there is an appropriate length of cable for each axis.

Recommended Support

This table gives the recommended maximum unsupported span for any LC40 device. These recommendations are based on a maximum beam deflection of 0.1 mm under its own weight. For certain applications more or less support may be warranted.

LC40 stages can be mounted to most 40 mm or 4040 T-slot extrusion framing systems or to a metric breadboard (using AB188 or AP191 accessories). For unsupported spans, bracing (AP244 or similar) can be added.

| Load (kg) | Maximum Span Between Supports (m) |

|---|---|

| 0 | 1.4 |

| 1 | 1.3 |

| 2 | 1.1 |

| 5 | 0.9 |

| 10 | 0.8 |

| 20 | 0.6 |

| 50 | 0.5 |

For spaced supports, supporting points should have a small contact surface, approximately 40 mm by 40 mm. For applications with more than 2 supports, ensure that all supporting surfaces share a common plane with less than 1 mm of deviation per m of separation and always fasten supports starting at the middle, working outwards.

Straightness of motion will depend on the location and orientation of supporting surfaces and installation procedure. If very low runout is required, pay careful attention to the coplanarity of support structures and measure and adjust for any horizontal deviation. A single continuous surface such as a surface plate or optical table with a reference edge can achieve better runout than spaced supports, but the degree will depend on the flatness of the surface and straightness of the reference edge.

If the free span of the Y-axis exceeds the recommended maximum span, the AP244Lxxxx braces or similar support members are recommended.

LC40 Gantry Assembly and Setup

Zaber's gantry products require some assembly and set-up upon arrival. These gantries can be disassembled, packed, and transported for use in new locations, or re-configured with new motion control axes to suit new applications. To set up your gantry, complete the following steps (where applicable).

Note: Instructions are provided for all hardware variants used in different gantry configurations. Not all hardware will be used in your configuration. Section headings will contain applicable part numbers.

Contact Zaber Customer Support at any time for help or additional information.

Preparation

- Unpack the high-flex motor cables and hang them vertically by one end for 24 hours to relieve packaging stresses. If the cables are too long to be hung up in one piece, loosely coil them on a flat surface into a large diameter such as 60 cm (2 ft).

- Unpack the brackets, cable guides and other hardware.

- Keep fasteners with their labelled bags to easily identify/locate the correct fastener for a step.

- Unpack the stage axes and identify the X-axis stages, Y-axis stage and any additional devices you may have.

- Determine stage orientations and locations of cable guide(s) and controller if you are using an external controller. The controller is typically located on the end of the gantry near the motor cable connections on the peripheral devices. It's preferable to mount it closer to X-axis 1, as this axis will carry the cable tracking. If the controller is required to be mounted at a significant distance from the gantry, longer cables or cable extensions may be necessary. See MC10T3(Lxxx) for longer 15 pin female to 26 pin male cables or MC10(Lxxx) for 26 pin female to 26 pin male extensions cables here: Zaber Accessories.

- Note: 'xxx' denotes a length in cm

- Identify the cables intended for each axis using the matching configuration table in the Product Overview.

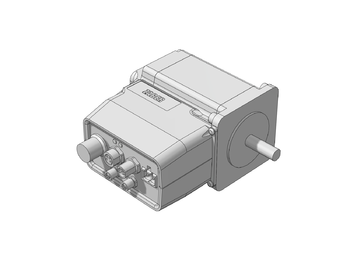

X-MCC Setup and Stage Connection

Related Products

|

MC10T3L060 MC10T3L300 MC10T3L450 |

|

Precautions

Important! Review the X-MCC User Manual for complete device precautions and operation instructions.

Important! Review the X-MCC User Manual for complete device precautions and operation instructions.

Important! Always remove power to the X-MCC controller before connecting or disconnecting peripherals.

Important! Always remove power to the X-MCC controller before connecting or disconnecting peripherals.

Assembly

-

Determine which MC motor cables are required for each gantry peripheral. See the configuration table in Product Overview.

-

Connect the 26 pin male end of the MC cables to the X-MCC controller axes. Connect the cable for:

•X-axis 1 to X-MCC axis 1

•X-axis 2 to X-MCC axis 2

•Y-axis to X-MCC axis 3

•Optional Z/theta to X-MCC axis 4 (if present)

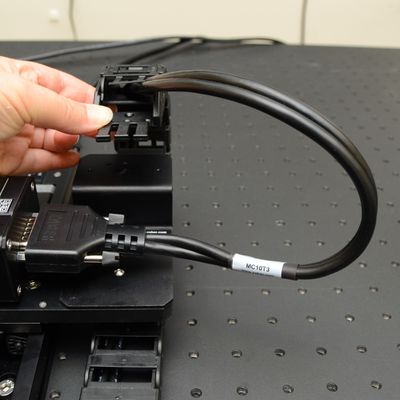

Tighten locking connector screws.

See Product Overview to identify the gantry axes. -

If desired, mount the X-MCC controller. See instructions in the X-MCC User Manual.

Note: Ensure the E-stop connector is reconnected with either the 'E-stop off' jumper or an E-stop (such as the ES01) to ensure controller function. -

Connect the other end of each MC motor cable to the matching peripheral and tighten the locking connector screws.

Important: During gantry assembly you may wish to disconnect one or more peripherals. Always remove power to the X-MCC before connecting or disconnecting any peripheral. -

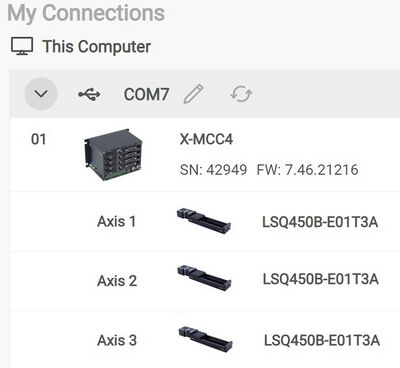

Connect the X-MCC controller to your computer using the USB cable (U-DC06) or to an X-JOY3 joystick with an X-DC cable (if a joystick is present).

Connect the X-MCC controller to one or more power supplies. -

Open Zaber Launcher. Confirm that three stages are detected and activated. If a stage is not activated, an "Activate" button will appear next to it. See the X-MCC manual for more information on activating peripherals and setup.

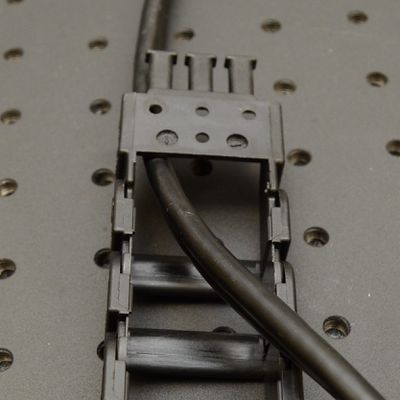

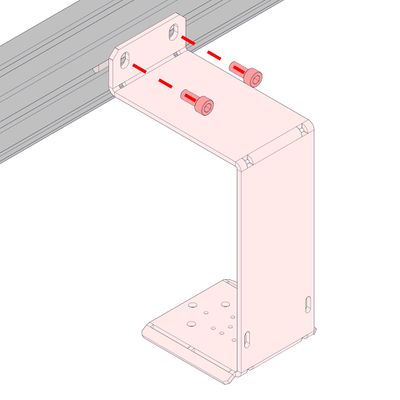

Roll-in T-Nut Installation

Tip: Roll-in T-nuts may be used for mounting various accessories to the LC40 extrusion slots.

Tip: Roll-in T-nuts may be used for mounting various accessories to the LC40 extrusion slots.

Required Tools

- small hex key

Installation

- Slide the T-nut into the slot sideways, then rotate it into position.

- If the T-nut feels like it is jammed, insert a small hex key through the threaded hole to apply more leverage.

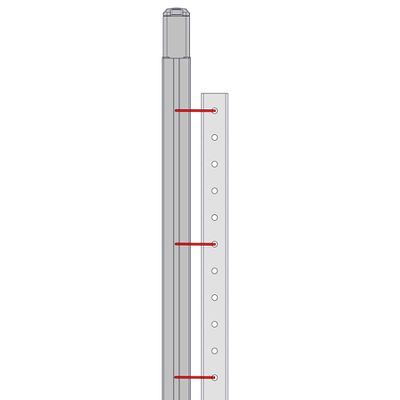

Installing Y-Axis Bracing

Related Products

|

Required Tools

- 5 mm hex key

Assembly

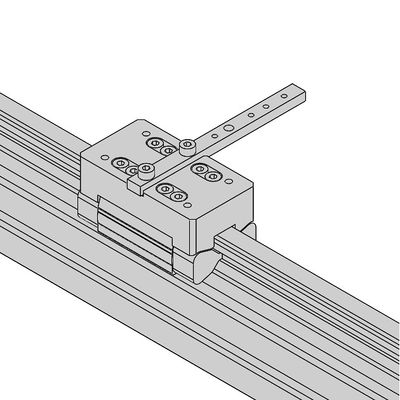

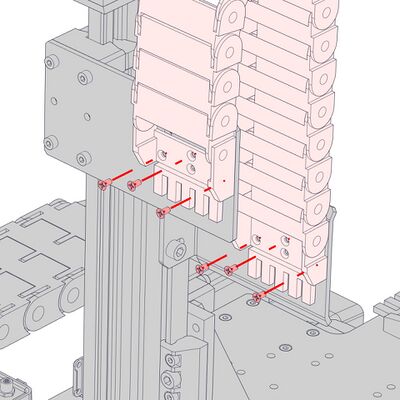

-

Install roll-in M8 T-nuts into the bottom of each of the Y-axis stages. Space the T-nuts along travel using every 5th hole in the AP244 (you may wish to make markings on the Y-axis stage(s) with a pen to align the T-nut and hole locations). To maintain mounting symmetry, add fasteners starting at each end and use smaller spacing in the middle.

Bracing should be centered on the length of the LC40. -

Install the AP244 bracing onto each Y-axis stage with M8 x 45 Flanged button cap screws and a 5 mm hex key.

-

Another method to assemble: Install the M8 T-nuts loosely onto the fasteners through the AP244, then slide the nuts into the LC40 slot until the AP244 is centered. Then, tighten the M8 screws using the 5 mm hex key.

LC40B Single Axis Setup: Installation of Motor and Home Limit Sensor

Notes

Important: If you are building a shaft-coupled LC40 gantry, first complete the X-axis shaft coupling instructions, then complete these motor assembly steps.

Required Tools

- 2 mm hex key

- 3 mm hex key

- 5 mm hex key

Motor Kit Installation

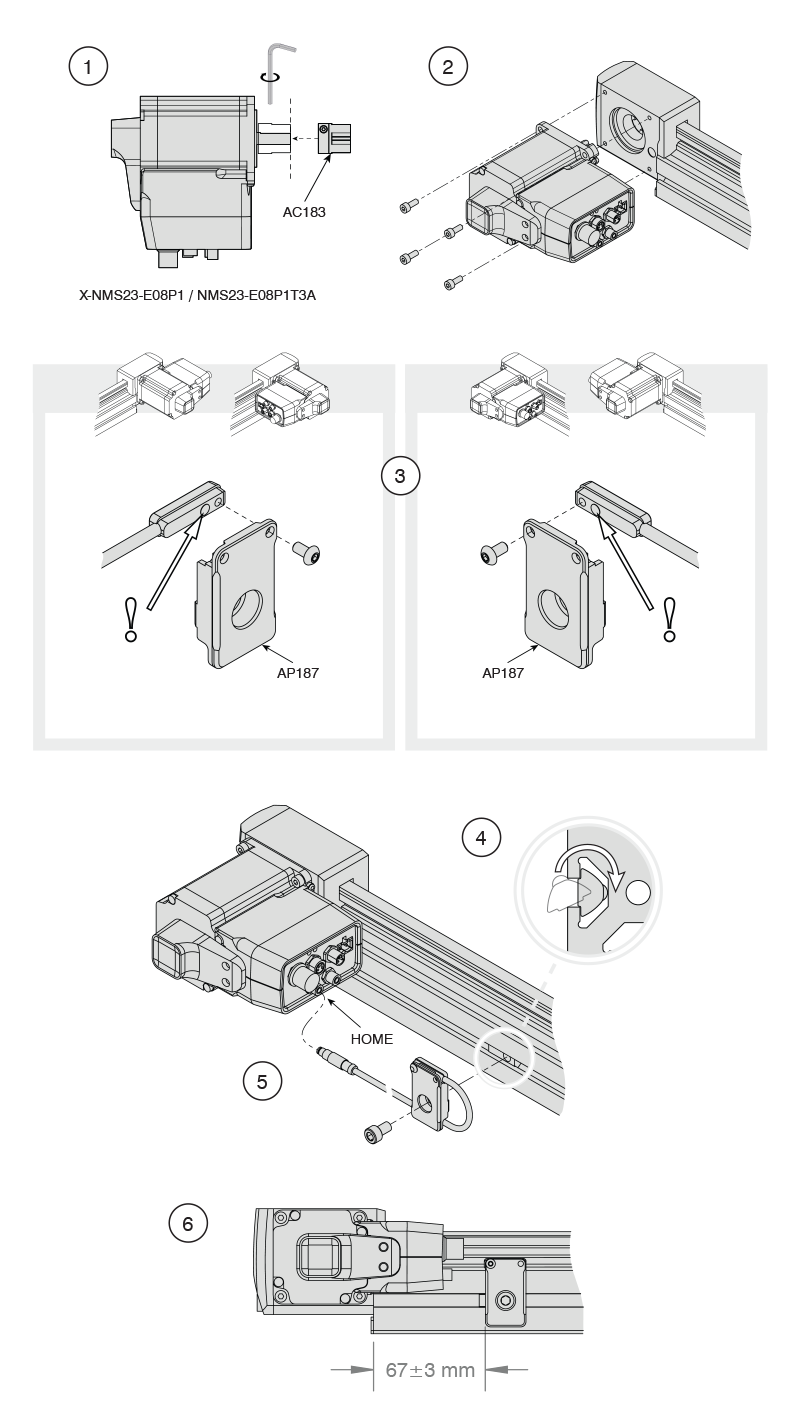

Note: X-NMS23-E08P1 motor is shown in the images below. The instructions are applicable for both X-NMS23-(B)E08P1 (motor with integrated controller) and NMS23-(B)E08P1T3A (motor without controller).

- Mount the clamping pulley coupling (AC183) flush to the end of the motor shaft. Tighten the coupling to the motor shaft using a 2 mm hex key.

- Insert the motor with coupling into the pulley bore of the LC40B linear guide. The motor can mount to either end of the guide and on either side, and the motor housing may point in any direction. The plastic covers over the pulley bore can be pried out with a 3 mm hex key. Secure the motor with M4 fasteners and 3 mm hex key.

- Fasten the home sensor (included with motor) to the AP187 bracket using a 2 mm hex key.

Important: The raised dot on the sensor should seat into the AP187 bracket. - Install an M6 T-nut into the side of the LC40B linear guide and attach the AP187 bracket with home sensor. The home sensor may be mounted to either side of the LC40B, but for easy wire routing it is recommended to mount it on the same side as the motor with the cable pointing away from the motor.

- Fasten the AP187 bracket to the T-nut using an M6 fastener and 5 mm hex key.

- Set the home sensor position to approximately 67 mm from the end of the extrusion. The carriage home position should be approximately 5 mm ahead of the travel hard limit.

If the home sensor is too close to the end of travel, the carriage may crash while homing.

Please use the LC40 Setup Application within Zaber Launcher to help configure the LC40B.

The motor controller can also be set up manually via the following steps if you choose not to use the LC40 Setup Application:

- If your drive kit is installed in a right-hand orientation, it will function right away. If the drive is installed in a left-handed orientation, the travel direction will need to be reversed in the controller settings. These commands can be executed with the following commands sent through the terminal in Zaber Launcher:

- set system.access 2

- set driver.dir 0

- set encoder.dir 1

- set system.access 1

- Set the maximum travel setting (limit.max) to match the physical travel of the device. When the stage only has one carriage, the travel in mm can be found from the 4 digits following LC40B on the product part number. When the stage has multiple carriages, the travel will need to be calculated manually based on the number of additional carriages, as well as the total spacing between the carriages.

- For example, part number 'LC40B1250' has a travel of 1250 mm. This travel should be multiplied by 142.222 to convert it to microsteps (rounded to an integer) and sent through the terminal as the command "set limit.max 177777"

- For part number 'LC40B1250-N2', with carriages spaced 80 mm apart, the maximum travel will be 1250 - 1 x (70 mm) - 80 mm = 1100 mm. This travel should be multiplied by 142.222 to convert it to microsteps (rounded to an integer) and sent through the terminal as the command "set limit.max 156444"

LC40C Single Axis Setup: Installation of Motor and Home Limit Sensor

Required Tools

- 2 mm hex key

- 3 mm hex key

- 5 mm hex key

Motor Kit Installation

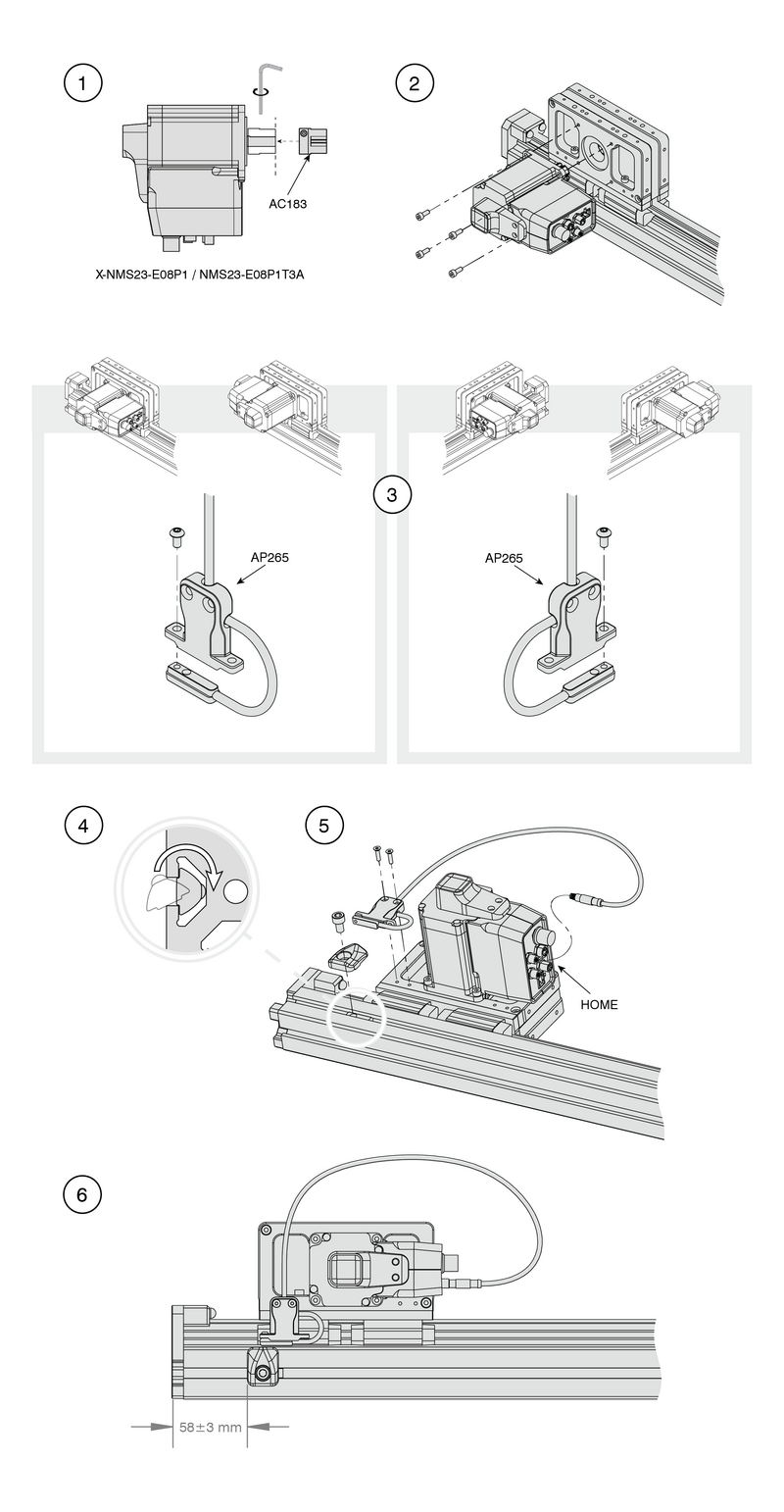

Note: X-NMS23-E08P1 motor is shown in the images below. The instructions are applicable for both X-NMS23-(B)E08P1 (motor with integrated controller) and NMS23-(B)E08P1T3A (motor without controller).

- Mount the clamping pulley coupling (AC183) flush to the end of the motor shaft. Tighten the coupling to the motor shaft using a 2 mm hex key.

- Insert the motor with coupling into the pulley bore of the LC40C linear guide. The motor can mount on either side, and the motor housing may point in any direction. The plastic covers over the pulley bore can be pried out with a 3 mm hex key. Secure the motor with M4 fasteners and 3 mm hex key.

- Fasten the home sensor (included with motor) to the AP265 limit sensor bracket using a 2 mm hex key.

- Install an M6 T-nut into the side of the LC40C linear guide for the AP265 limit sensor magnet. The home sensor and magnet may be mounted to either side of the LC40C, but for easy wire routing it is recommended to mount it on the same side as the motor.

- Attach the AP265 magnet to the T-nut using an M6 fastener and 5 mm hex key. Attach the AP265 limit sensor bracket with home sensor with M3 countersink fasteners using a 2 mm hex key onto the side of the LC40C carriage. Route the cable through the slot on the back of the limit sensor bracket. The bracket should be on the end of the carriage towards the home direction with the cable pointing toward the motor.

- Set the magnet position to approximately 58 mm from the end of the extrusion.

Please use the LC40 Setup Application within Zaber Launcher to help configure the LC40C.

The app will perform a test that moves the stage through the full travel range. Ensure the stage is securely mounted before performing this step.

The app will perform a test that moves the stage through the full travel range. Ensure the stage is securely mounted before performing this step.

The motor controller can also be set up manually via the following steps if you choose not to use the LC40 Setup Application:

- If your drive kit is installed in a left-hand orientation, it will function right away. If the drive is installed in a right-hand orientation, the travel direction will need to be reversed in the controller settings. These commands can be executed with the following commands sent through the terminal in Zaber Launcher:

- set system.access 2

- set driver.dir 0

- set encoder.dir 1

- set system.access 1

- Set the maximum travel setting (limit.max) to match the physical travel of the device. The travel in mm can be found from the 4 digits following LC40C on the product part number.

- For example, part number 'LC40C0450' has a travel of 450 mm. This travel should be multiplied by 142.222 to convert it to microsteps (rounded to an integer) and sent through the terminal as the command "set limit.max 64000"

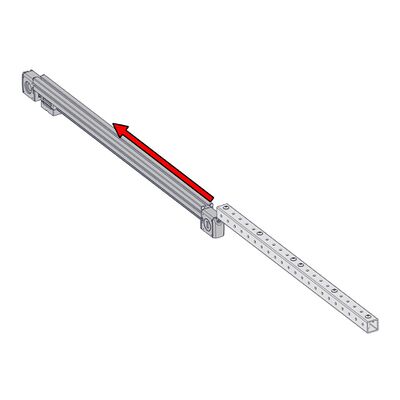

Shaft Coupling Setup: Installation of Motor and Shaft

Note: This instruction applies only to shaft-coupled gantries. For all other assemblies, move onto the next section.

Related Products

|

|

|

|

|

Required Tools

- 2 mm hex key

- 3 mm hex key

Assembly

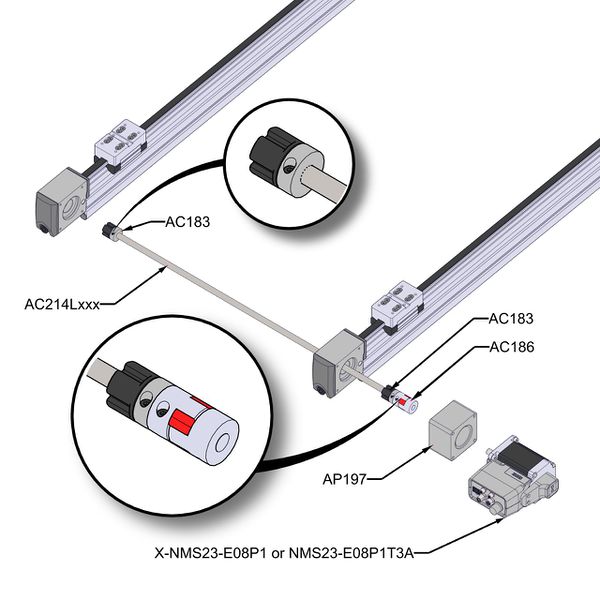

- Slide the AC183 pulley coupling onto the AC214Lxxx coupling shaft in the orientation shown and leave it loose.

- Insert the AC214Lxxx coupling shaft into the end of the AC186 coupling (the red spider coupling) as far as it will go. Use the 2 mm hex key to tighten the AC186 coupling in place.

- Push the AC183 pulley coupling against the AC186 jaw coupling and tighten it using the same hex key.

- Slide the shaft with both couplings through the pulley bore on the side of the gantry where the motor will be mounted.

- Place the AP197 NEMA23 standoff over the coupling shaft against the pulley bore of the LC40, so that it sits between the motor and the pulley bore.

- Insert the motor shaft into the AC186 jaw coupling. It should be pressed as far down on the shaft as possible. Tighten in place using the 2 mm hex key.

- Install the second pulley coupling on the other end of the coupling shaft loosely, in the orientation shown.

- Pull the carriages on both X-axis stages by hand to their hard stop position close to the shaft.

- Use light pressure to engage both pulley couplings with their respective pulley bores, but don't fully insert them yet.

- Tighten the second pulley coupling to the end of the shaft using the hex key, then firmly press the entire shaft and coupling assembly into both pulley bores.

- Press the motor into the AP197 NEMA23 standoff onto the pulley housing. It should align itself with the bore.

- Press the motor and standoff onto the pulley housing. Ensure the connectors on the motor are facing away from the LC40 stage.

- Install the four screws packed with AP197 through the flange into the pulley housing, then install the motor into the adaptor and tighten all screws with the 3 mm hex key.

- Complete the AP187 Limit Sensor Mount assembly by following the instructions in Single Axis Setup: Installation of Motor and Home Limit Sensor for the X-axis, and then complete the Y-axis stage motor assembly following the instructions below.

Installing AB189 Alignment Bar

Related Products

|

|

Required Tools

- 3 mm hex key

Assembly

- Orient the alignment bar (AB189) towards the working space of your gantry by default (although it can be mounted in either direction for most applications). With AP244 bracing, you may need to orient the bar outside the working space.

- Seat the alignment bar into the groove of the LC40 carriage and tighten both screws with a 3 mm hex key

- Make sure to install an alignment bar onto each X-axis carriage

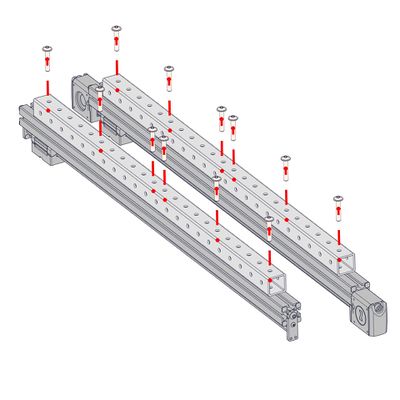

Assembly of AB188 Mounting Clamps

Related Products

|

|

|

Precautions

Important: Make sure that all of your devices work individually before proceeding with this step.

Important: Make sure that all of your devices work individually before proceeding with this step.

Required Tools

- 3 mm hex key

Assembly

- Securely mount one of the X-axes to your structure, allow the other to float freely.

- Temporarily remove the motor from any motorized Y-axis stage(s) to allow access to the mounting holes for the AB188.

- Place the Y-axis on top of the X-axis carriages so that the AB189 alignment bars seat into the T-slot of the Y-axis.

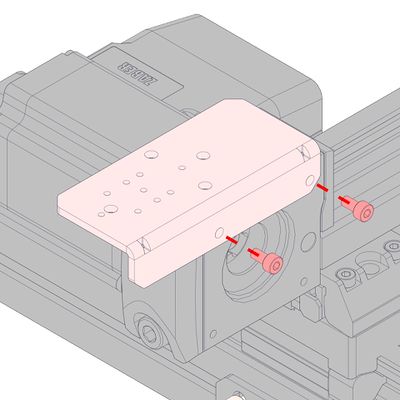

- Install the AB188 clamps into the slots on the side of the Y-axis.

- Square the Y-axis to the fixed side of the X-axis and tighten the screws on the AB188 clamps. Repeat for the floating side.

- Adjust the carriage position of either X-axis device until you are satisfied with the alignment.

- If using two X-axis motors with an external controller, set up lockstep now.

- Run the joined X-axis through its full range of travel, and secure the floating side to your structure.

- Torque all of the screws in the clamps to 3 Nm, or very tight by hand feel.

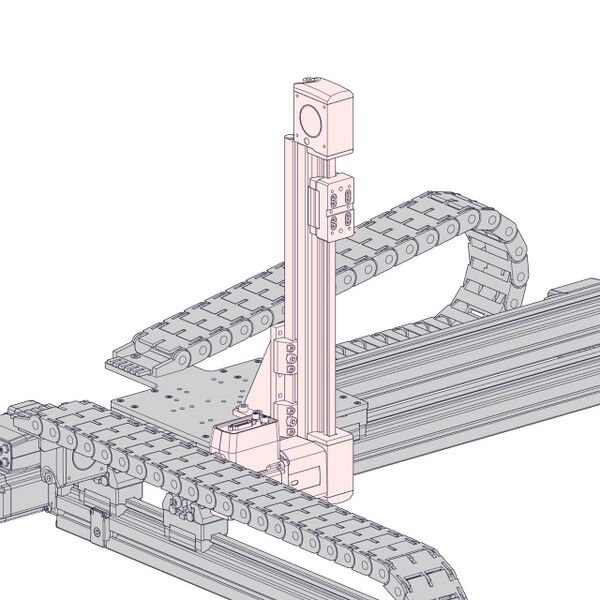

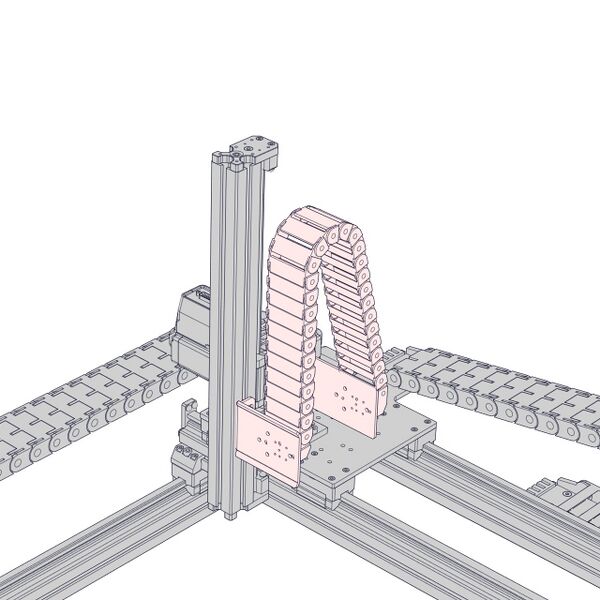

Z-Axis Installation

Related Products

Note: Not all systems will require all of the listed parts.

|

|

|

|

|

|

|

Required Tools

- 3 mm hex key

- 5 mm hex key

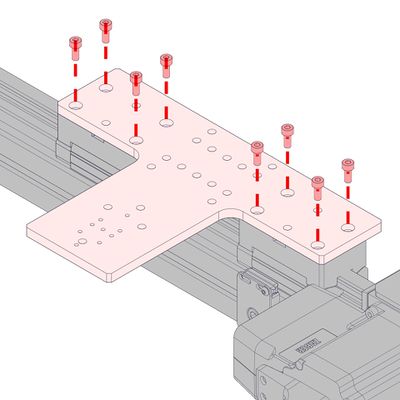

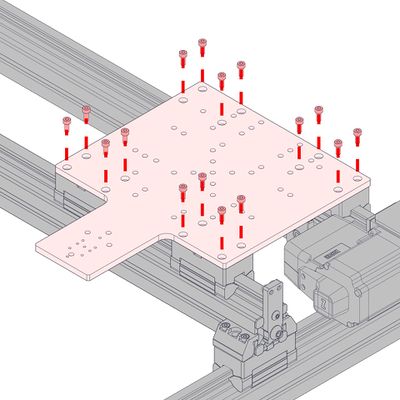

LC40B Assembly

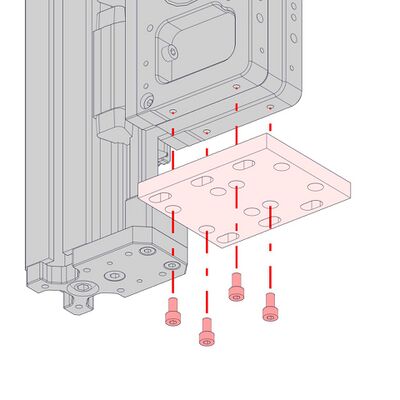

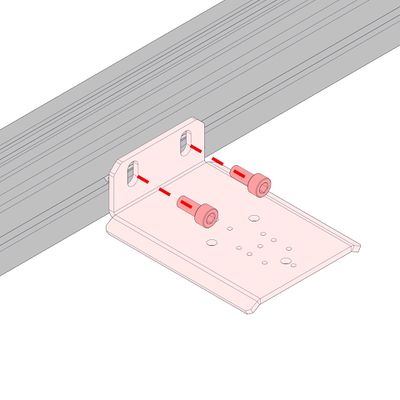

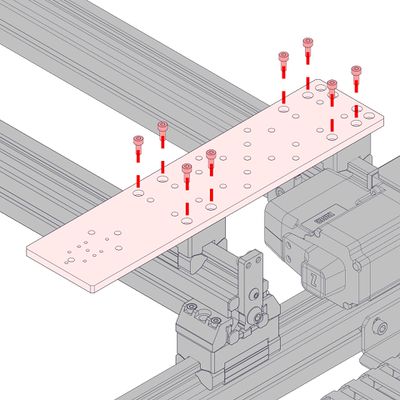

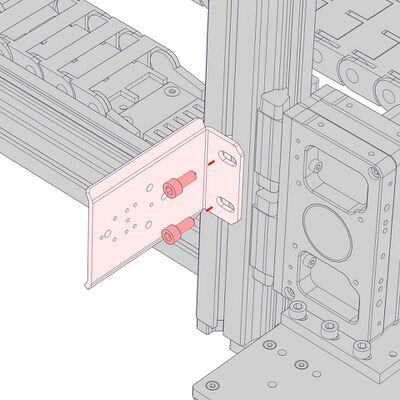

- Place the AB104 angle bracket on the top plate and align the 6 slotted holes with the centered hole pattern of the AB246 quad carriage plate.

- Using 6 x M6x14mm screws through the slotted holes, mount the angle bracket to AB246.

- Press the completed LC40 Z-axis stage assembly against the vertical edge of the AB104 bracket. We recommend having the motor at the end closest to the connection with AB104 for better weight distribution during acceleration.

- While supporting the Z-axis against AB104, install the 4 x AB188 mounting clamps to hold it into position.

- Ensure the Z-axis motor doesn’t contact either of the X-axis guides by cycling the Y-axis through travel. If it does contact, loosen off the AB288 clamps and raise the Z-axis stage until there is clearance.

- Square the Z-axis against the Y-axis before tightening the 4 x AB188 mounting clamps to secure it in position.

- Torque all of the screws in the clamps to 3 Nm, or very tight by hand feel

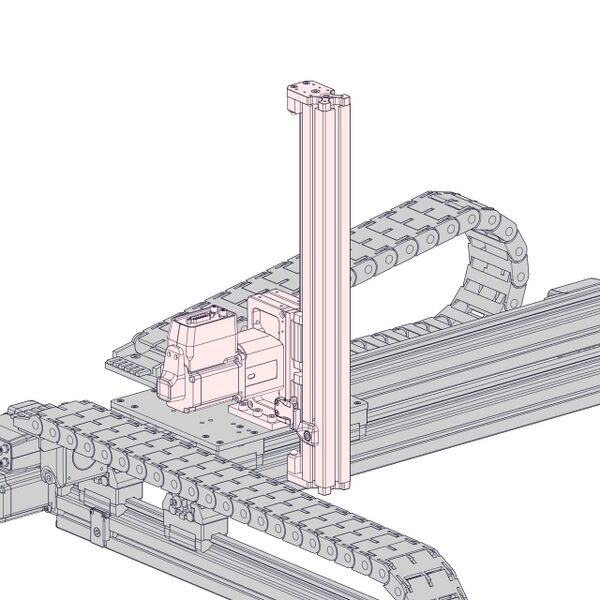

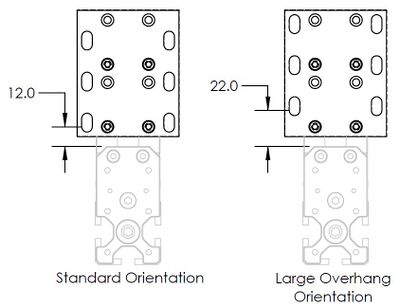

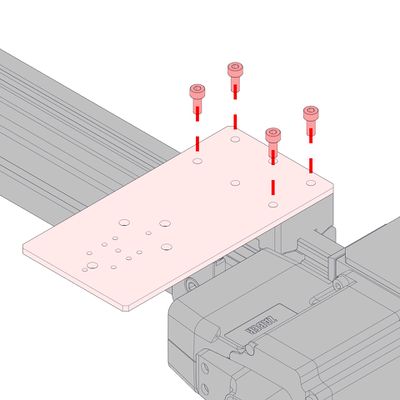

LC40C Assembly

- If the motor is installed on the stage, temporarily remove it so that the mounting screws can be accessed.

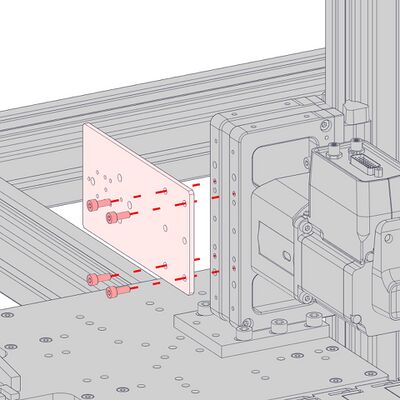

- Attach the AP266 mounting plate with 4x M4 x 8 screws to the bottom of the pulley housing. The plate can be attached in two different orientations to give different amounts of overhang. It is recommended to start with the standard orientation and switch to the large overhand orientation if additional overhang is necessary.

- Place the stage on the top plate and align the 6 slotted holes with the centered hole pattern of the AB246 quad carriage plate

- Using 6 x M6x14mm screws through the slotted holes, mount the LC40C to the AB246.

- Manually move the stage to check that there are no clashes. If necessary, remove the stage and rotate the AP266 mounting plate to the large overhang orientation and reinstall.

- Reinstall the motor.

CG Cable Guide and Cable Assembly

Related Products

|

|

|

|

|

|

|

|

MC10T3L060 MC10T3L300 MC10T3L450 |

|

Precautions

Important: Ensure cables are not twisted along their length. This can reduce cable lifetime.

Important: Ensure cables are not twisted along their length. This can reduce cable lifetime.

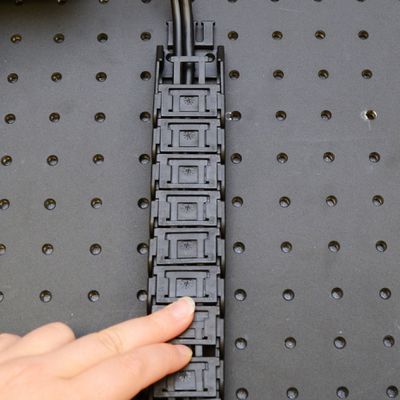

Assembly

-

Ensure all motor cables are connected to the correct peripherals before building the cable guides.

-

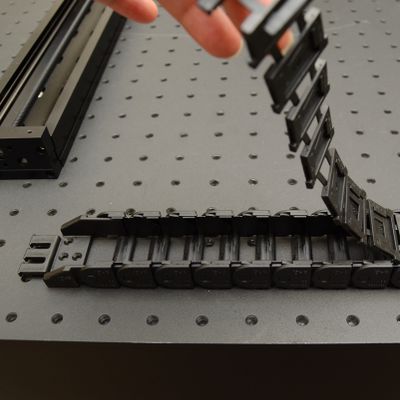

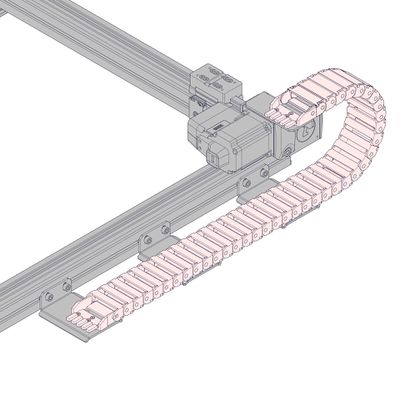

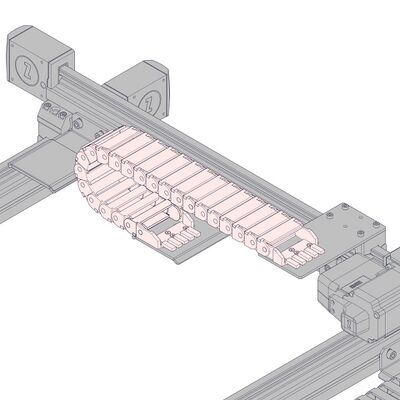

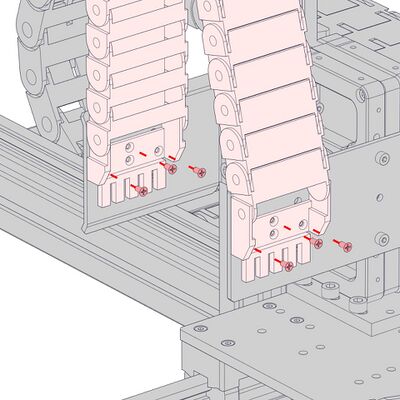

Determine the number of links required for the guide in each axis. See Appendix B: Cable Guide Links for specific quantities.

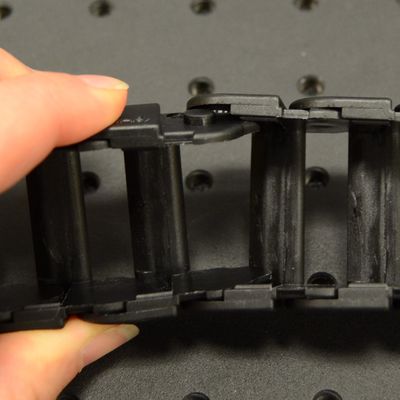

Peel open the cable guide. -

Break the CGxx chain at the appropriate position.

-

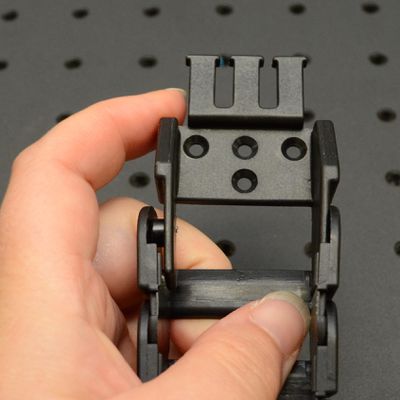

Attach the CGxxT parts to the mating ends of the CGxx.

Note: You may need to remove these temporarily to attach them to the mounting adaptors.

Note: For an LC40C Z-axis with inline mounted CG01 cable guide see LC40C CG01T Assembly for additional instructions for attaching CG01T. -

Lay out the cable guide and determine which way it will bend and where the CGxxT terminations will mount to the cable guide adaptors.

Note: If using CG06T, the pivoting termination should mount to the upper cable guide adapter. -

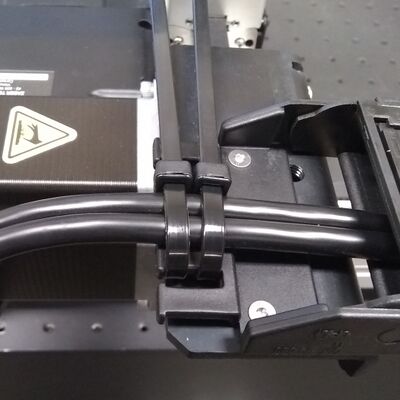

Lay cables in the guides, ensuring that the peripheral connectors are exiting the top end of the guide. Remove any twists in the cable(s) and lay them in the centre of the guide. Minimize twists outside the cable guide.

Important: If you are using a Y-axis cable guide, ensure that the cable(s) for the Z/theta axis and any end effectors are also included in the X-axis cable guide. -

Close the CGxx cable guide by clicking the parts together.

Note: The CGxx cable guide parts must be oriented as shown to click together. -

Ensure 150-200 mm (6-8 inches) of cable length extends from the top end of the cable guide where it will connect.

-

Terminations can be attached in two orientations, depending on how they will attach to the mounting adaptors. If the termination needs to be flipped, you will need to assemble the cable in the guide then remove and re-attach the termination as shown.

LC40C CG01T Assembly

Follow the instructions below to assemble CG01 cable guides for inline cable guide mounting on a LC40C.

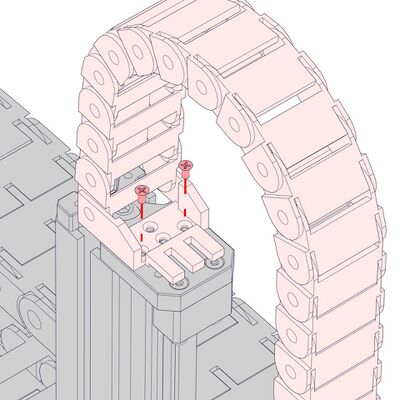

-

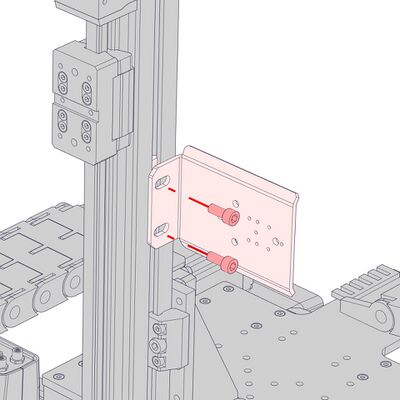

Attach the CG01T mating end with the through holes pivoted 90° as shown. The end should be pointing inwards towards the cable guide bend.

-

Attach the other mating end as normal. This will attach to the stationary pulley housing.

-

The cable guides should be mounted to the LC40C as shown, with the rotated end attaching to the end of the column and the other straight end attaching to the pulley housing.

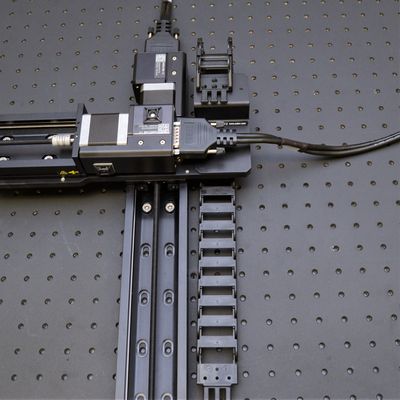

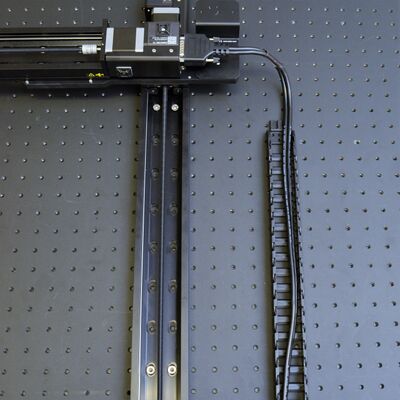

Installing X-Axis Cable Guide Supports

Note: Instructions below are provided for both inverted and standard orientation gantries. Not all systems will require all of the listed parts.

Related Products

|

|

|

Required Tools

- 5 mm hex key

- 3 mm hex key

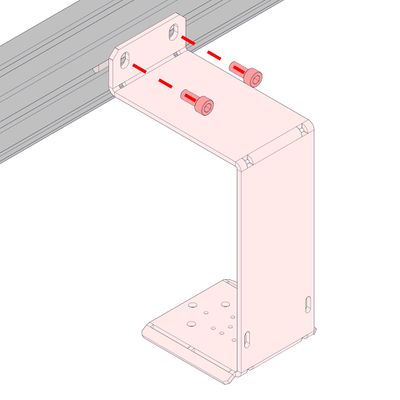

Installing Fixed Supports

-

Install roll-in T-nuts into side of the X-axis stage closest to the Y-axis stage motor. Install 2 x T-nuts for each cable guide support, spacing the supports approximately 200 mm apart, starting at the mid-point of the physical travel and continuing to the end of travel away from the X-axis motor.

-

Install the AP235 (standard orientation) or AP239 (inverted orientation) supports using 2 x M6 x 14 screws and the 5 mm hex key. Slide the supports along the extrusion to the desired locations, then tighten the fasteners.

-

AP239 is shown here for inverted gantries.

-

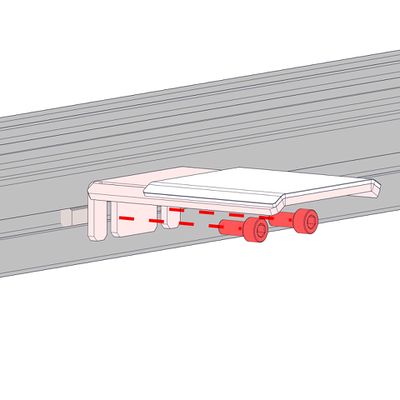

OPTIONAL: Remove the adhesive back and apply foam to the AP235 or AP239 supports as shown to reduce noise and wear.

Important: Do not apply foam to the AP235 or AP239 support in the middle of travel. This is where your cable guide termination will be attached.

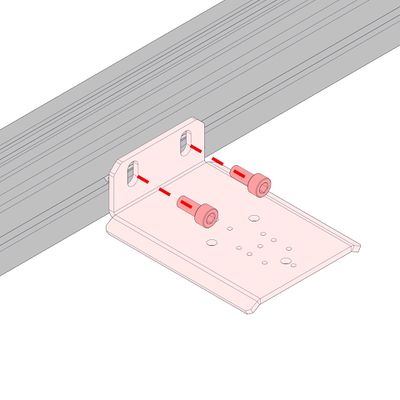

Installing Moving Support

-

Attach the AP237 moving support plate to the Y-axis pulley housing using 2 x M4 x 8 screws and the 3 mm hex key.

Installing Cable Guide

-

Move the Y-axis carriage to the home position. Install the cable guide by attaching the terminations to the mid-travel AP235 or AP239 support, and to the AP237 support.

See CG Cable Guide and Cable Assembly for details on assembling the cable guides and Cable Management for important information on securing cables. -

Check that the X-axis can reach both ends of travel. If it does not, adjust the positions of the AP235/AP239 supports as needed.

Installing Y-Axis Cable Guide Supports

Note: Instructions below are provided for both inverted and standard orientation gantries, and systems will single, double or quadruple carriages. Not all systems will require all of the listed parts.

Related Products

|

|

|

|

|

|

Required Tools

- 5 mm hex key

- 3 mm hex key

Installing Fixed Supports

-

Install roll-in T-nuts into side of the Y-axis stage you intend to mount the cable guide beside. Install 2 x T-nuts for each cable guide support, spacing the supports approximately 200 mm apart, starting at the mid-point of the physical travel and continuing to the end of travel.

-

Install the AP235 (standard orientation) or AP239 (inverted orientation) supports using 2 x M6 x 14 screws and the 5 mm hex key. Slide the supports along the extrusion to the desired locations, then tighten the fasteners.

-

AP239 shown for inverted gantries

-

OPTIONAL: Remove the adhesive back and apply foam to the AP235 or AP239 supports as shown to reduce noise and wear.

Important: Do not apply foam to the AP235 or AP239 support in the middle of travel. This is where your cable guide termination will be attached.

Installing Moving Support

-

Attach the moving support plate (AP238, AP245, AP246 or AP247) to the Y-axis carriage(s) using the provided M4 x 8 screws and the 3 mm hex key.

AP238 is shown here. -

AP245, for use with dual in-line carriages is shown here.

-

AP246, for use with quadruple (dual X and Y) carriages is shown here.

-

AP247, for use with dual parallel carriages is shown here.

Installing Cable Guide

-

Install the cable guide by attaching the terminations to the mid-travel AP235 or AP239 support, and to the moving support (AP238, AP245, AP246 or AP247, depending on the number of carriages).

See CG Cable Guide and Cable Assembly for details on assembling the cable guides and Cable Management for important information on securing cables. -

Check that the Y-axis carriage can reach both ends of travel. If it does not, adjust the positions of the AP235/AP239 supports as needed.

Check that the X-axis can reach both ends of travel without any interference from the cable guide.

Installing Z-axis Cable Guide Supports

Note: Not all systems will require all of the listed parts.

Related Products

|

|

Required Tools

- 5 mm hex key

- 3 mm hex key

- #1 Phillips-head screwdriver

LC40B Z-axis

-

Install 2 x roll-in T-nuts into the side of the Z-axis stage you intend to mount the cable guide beside.

-

Install the AP235 support using 2 x M6 x 14 screws and the 5 mm hex key. Slide the support along the extrusion to the desired locations, then tighten the fasteners.

-

Attach the AP238 moving support plate to the Z-axis carriage using the provided M4 x 8 screws and the 3 mm hex key.

-

Install the cable guide by attaching the terminations to the AP235 support and the AP238 moving support.

See CG Cable Guide and Cable Assembly for details on assembling the cable guides and Cable Management for important information on securing cables. -

Check that the Z-axis carriage can reach both ends of travel. If it does not, adjust the positions of the AP235 support as needed.

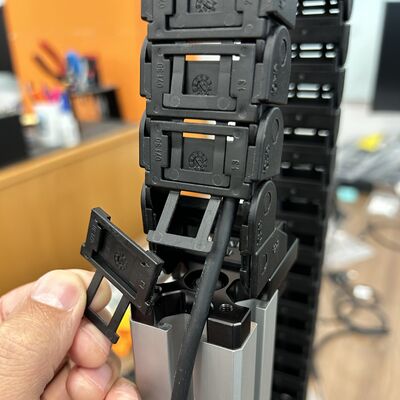

LC40C Z-Axis

CG01, Inline Mounted

CG01 cable guides attach directly to the stage with M3 countersink screws. No cable guide supports are required for this configuration.

-

Attach the end of the cable guide with the rotated termination to the end plate of the column with 2 x M3 countersink screws.

See CG Cable Guide and Cable Assembly for details on assembling the cable guides and Cable Management for important information on securing cables. -

Attach the other end to the pulley housing with 2 x M3 countersink screws.

-

After attaching the cable guide to the end plate remove as many covers from the links as necessary for the cable to freely exit the cable guide.

-

Check that the Z-axis can reach both ends of travel.

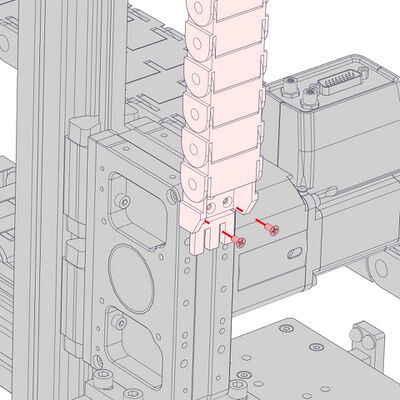

Other Cable Guides, Side Mounted

-

Install 2 x roll-in T-nuts into the side of the Z-axis stage you intend to mount the cable guide beside.

-

Install the AP235 support using 2 x M6 x 14 screws and the 5 mm hex key. Slide the support along the extrusion to the desired locations, then tighten the fasteners.

-

Attach the AP238 plate to the Z-axis pulley housing using the provided M4 x 8 screws and the 3 mm hex key.

-

Install the cable guide by attaching the terminations to the AP235 and AP238 supports.

See CG Cable Guide and Cable Assembly for details on assembling the cable guides and Cable Management for important information on securing cables. -

Check that the Z-axis can reach both ends of travel. If it does not, adjust the positions of the AP235 support as needed.

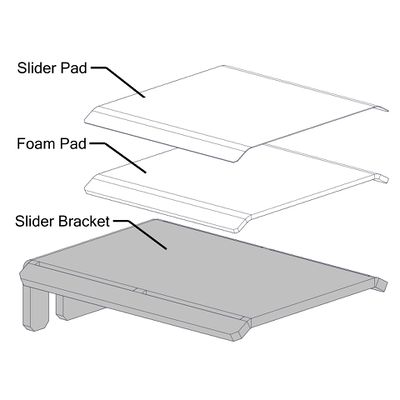

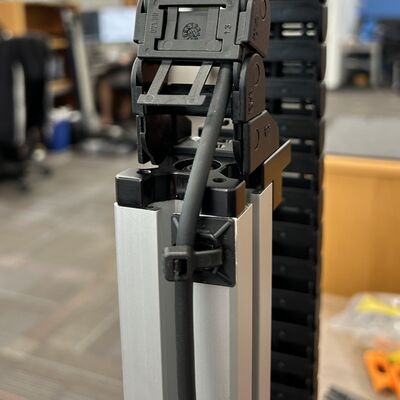

Installing Cable Guide Sliders

Sliders are recommended for cable guides supporting travel equal to or greater than 1500 mm.

Related Products

|

|

Required Tools

- 5 mm hex key

- 3 mm hex key

Assembly

-

Remove adhesive backs, then apply foam, followed by slider pad to the contact surface of the AP236 or AP241 parts.

-

Sliders should be installed on top of cable guide supports in the 'home' end of travel where the cable guide may sag downwards.

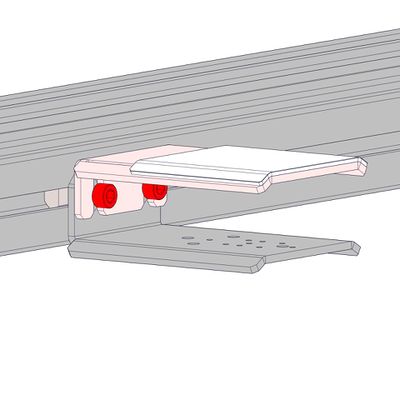

AP236 Installation for Standard Orientation

-

To install an AP236 slider on top of an AP235 support, loosen the screws for the previously installed AP235 support guide and slide the slotted edge of the AP236 under the screw heads.

-

To install an AP236 slider by itself, insert a T-nut into the side of the LC40 extrusion, and fasten the AP236 in place using 2 x M6 x 14 screws and the 5 mm hex key.

Adjust the slider height and alignment to ensure a straight path for the cable guide and retighten the cable guide support screws using the 5 mm hex key.

AP241 Installation for Inverted Orientation

-

To install an AP241 slider, use 2 x M3 x 6 screws to mount the slider to the AP239 inverted cable guide support.

Cable Management

Related Products

|

|

|

MC10T3L060 MC10T3L300 MC10T3L450 |

MC10L060 MC10L300 MC10L450 |

Precautions

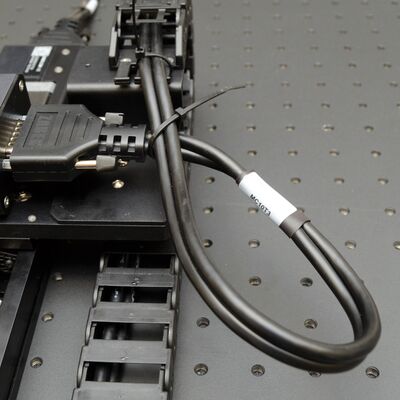

Important: Creating a loop in the cable of 150 to 200 mm (6-8 inches), between the top cable guide mount and the Y-axis stage, protects the cable and increases cycle lifetime.

Important: Creating a loop in the cable of 150 to 200 mm (6-8 inches), between the top cable guide mount and the Y-axis stage, protects the cable and increases cycle lifetime.

Required Tools

- cable ties

- cable tie mounts

- scissors

Assembly

-

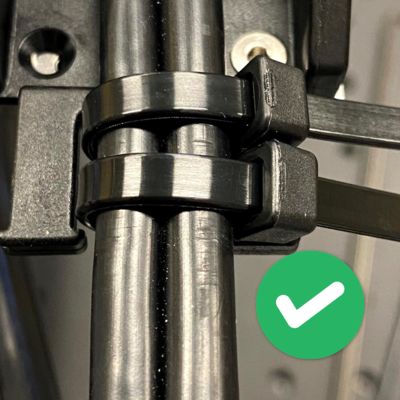

Use cable ties (provided in CGxxT kit) to loosely secure cables to the prongs on the CGxxT as shown, to restrict their motion.

-

Where there are no prongs available, use adhesive-backed cable tie mounts (provided in the CGxxT kit) to secure cables to a surface near the exit of the cable guide.

-

Create the loop of cable using at least 150 to 200 mm (6-8 inches) of cable, for each cable as it exits the guide.

-

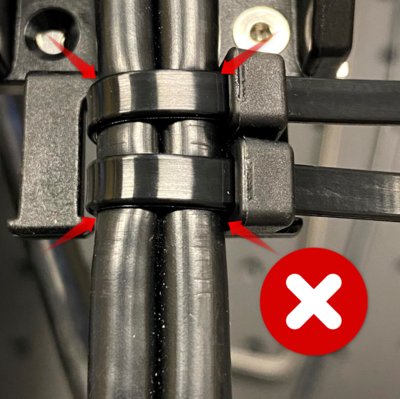

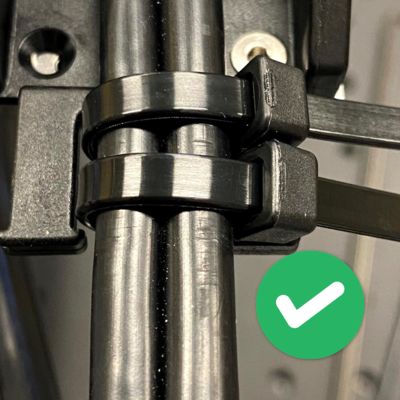

To create the upper strain relief tighten two cable ties on the upper prongs of the CGxxT and the cable. The cable ties should be loose enough that you can move the cable though them fairly easily by hand, but tight enough to constrain the external cable jacket. This allows the internal cable wires to move through the strain relief to relieve bending stresses during motion.

-

The cable ties in this image have been overtightened and are pinching the cable jacket. Remove ties and start again if needed.

-

Adjust the cable position inside the guide.

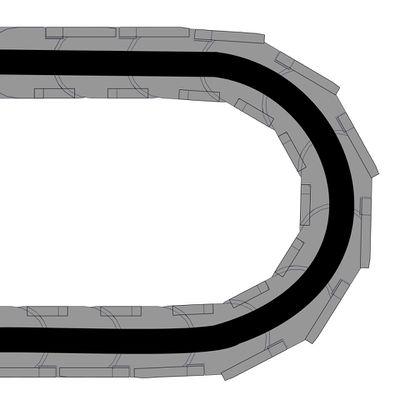

1. The cable should be in the centre of the guide, not pulled tight against the inner radius or pushed against the outer radius of the bend.

2. Holding the cable gently on the controller side of the cable, move the stage along its entire range of travel several times and ensure the cable runs freely in the guide. -

Tighten the cable tie on the second CGxxT prongs to create the lower strain relief, matching the snugness of the first termination.

Trim the ends of the cable ties.

Disassembly

To disassemble, follow the assembly procedures in reverse. Please keep the following guidelines in mind:

- Remove power before attempting to disassemble devices to prevent unexpected motion

- Retain fasteners for future use

- Keep cable guide assemblies intact

Operation

Setting Lockstep Tolerance

The lockstep tolerance limits the amount of twist between the two lockstepped stages as they travel. If the tolerance is exceeded, the devices will be brought to a stop, to prevent device damage from excessive twist. We recommend adjusting the default setting to larger values (up to the maximum safe values presented below for your specific configuration). Setting a larger tolerance reduces the risk of unexpected or jarring stops and should not affect the typical operating performance of the lockstepped stages.

| Distance Between X-Axis Stages | Lockstep Tolerance (microsteps) |

| 100 | 0 (unlimited) |

| 200 | 0 (unlimited) |

| 300 | 0 (unlimited) |

| 350 | 0 (unlimited) |

| 400 | 94 |

| 500 | 134 |

| 600 | 160 |

| 700 | 187 |

| 800 | 214 |

| 900 | 241 |

| 1000 | 267 |

| 1250 | 334 |

| 1500 | 401 |

| 1750 | 468 |

| 2000 | 535 |

| 2250 | 601 |

| 2500 | 668 |

| 2750 | 735 |

| 3000 | 802 |

| 3250 | 869 |

| 3500 | 936 |

Dual Motor X-Axis Thrust

In the dual motor configuration, the load split between the two X-axis motors will not be consistent at every position. When pushing against a load or resistance exactly halfway between the two X-axes, the load will be shared perfectly between both motors, increasing the total thrust available, but approaching either end of the Y-axis the load will be shared less evenly, decreasing the total thrust. The table below gives the approximate worst case load sharing. These values are approximate because they will also be affected by the stiffness of the assembled joints and the length of the belt in the X-axis. Doubling the Y-axis rails with a quad carriage plate will significantly improve these numbers.

| Y-Axis Maximum Travel (mm) | Worst Case Load Ratio (%/%) |

|---|---|

| 100 | 71/29 |

| 200 | 73/28 |

| 500 | 76/24 |

| 1000 | 80/20 |

| 2000 | 85/15 |

| 3000 | 88/12 |

Device Product Manuals

Zaber's gantry products include combinations of several Zaber motion control devices. For device operation, maintenance procedures and troubleshooting, consult the detailed product manuals for these devices:

- X-MCC Universal Drive Controller

- These controllers are available with 1-4 axes. In a gantry, a three or four axis controller is typically used to operate the two X-axis stages in lockstep, and to provide coordinated motion for up to two additional axes of motion. This controller may be daisy-chained with other Zaber controllers or motion devices with integrated control.

- LSQ-E Linear Stage

- Provides X,Y and optional Z axis linear motion in LSQ-E Gantries.

- LSQ-EC Linear Stage

- Provides X,Y and optional Z axis linear motion in LSQ-EC Gantries.

- LRT-EC Linear Stage

- Provides X,Y and optional Z axis linear motion in LRT-EC Gantries.

- LC40B-KM01 Linear Guide with Integrated Controller Motor Kit

- Provides X,Y linear motion in LC40 Gantries.

- LC40B-KM02 Linear Guide with Motor Kit for External Controller

- Provides X,Y linear motion in LC40 Gantries.

- LC40C-KM03 Linear Cantilever Axis with Integrated Controller Motor Kit

- Provides X,Y linear motion in LC40 Gantries.

- LC40C-KM04 Linear Cantilever Axis with Motor Kit for External Controller

- Provides X,Y linear motion in LC40 Gantries.

- RSW Rotary Stage

- Provides and optional rotary axis to a gantry.

Additional Zaber motion products can be used in any Zaber gantry. Product Manuals can be found through their product pages here: Zaber Products

Older Versions of This Document

This document is updated regularly to reference new components and procedures. For older systems, it may be helpful to refer to the archived instructions closest to the purchase date:

Troubleshooting a Gantry product

The following sections contain tips for troubleshooting gantry behavior. Please also see the Device Product Manuals for individual stage behavior, indicator information, and additional troubleshooting.

Unexpected Behaviour

- An axis doesn't respond to a move command.

- The axis stage(s) may need to be homed before use. Send the home command, or the lockstep home command if the axis is in a lockstep group (X-axis).

- Ensure commands addressed to lockstep group stages (X-axis) are lockstep motion commands.

- A peripheral won’t move and move commands are rejected.

- The peripheral may have been unplugged and plugged back in to the wrong axis. Send the activate command the peripheral to continue using it.

- The device is moving on its own and running against the ends of travel.

- The position encoder has de-synchronized.

- Reset the device by power cycling it or sending the system reset (T:0) command, then re-initialize it with the home (T:1) command.

- The X-axis stages have stopped unexpectedly during a move.

- See warning flags for more information.

- A stage may have stalled. See X-MCC Troubleshooting.

- Lockstep twist tolerance may have been exceeded. Consider adjusting lockstep tolerance. See Operation section for maximum recommended settings.

- Lockstepped Stages Stuck or Not Moving Well

- Alignment may not be ideal or stages may have become twisted.

- Disable the lockstep group by sending lockstep setup disable. Typically this will look like 'lockstep 1 setup disable'.

- Perform alignment steps, homing, and lockstep setup again.

Warranty and Repair

For Zaber's policies on warranty and repair, please refer to the Ordering Policies.

Standard products

Standard products are any part numbers that do not contain the suffix ENG followed by a 4 digit number. Most, but not all, standard products are listed for sale on our website. All standard Zaber products are backed by a one-month satisfaction guarantee. If you are not satisfied with your purchase, we will refund your payment minus any shipping charges. Goods must be in brand new saleable condition with no marks. Zaber products are guaranteed for one year. During this period Zaber will repair any products with faults due to manufacturing defects, free of charge.

Custom products

Custom products are any part numbers containing the suffix ENG followed by a 4 digit number. Each of these products has been designed for a custom application for a particular customer. Custom products are guaranteed for one year, unless explicitly stated otherwise. During this period Zaber will repair any products with faults due to manufacturing defects, free of charge.

How to return products

Customers with devices in need of return or repair should contact Zaber to obtain an RMA form which must be filled out and sent back to us to receive an RMA number. The RMA form contains instructions for packing and returning the device. The specified RMA number must be included on the shipment to ensure timely processing.

Email Updates

If you would like to receive our periodic email newsletter including product updates and promotions.

Contact Information

Contact Zaber Technologies Inc by any of the following methods:

| Phone | 1-604-569-3780 (direct) 1-888-276-8033 (toll free in North America) |

|---|---|

| Fax | 1-604-648-8033 |

| #2 - 605 West Kent Ave. N., Vancouver, British Columbia, Canada, V6P 6T7 | |

| Web | www.zaber.com |

| Please visit our website for up to date email contact information. |

The original instructions for this product are available at https://www.zaber.com/manuals/LC40-GANTRY.

Appendix A: Default Settings

Please see the Zaber Support Page for default settings for this device.

Appendix B: Cable Guide Links

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Drawing

Specifications

This product uses the FreeRTOS kernel. FreeRTOS is © 2026 Amazon.com, Inc. or its affiliates and is governed by the following license:

All rights reserved.

Permission is hereby granted, free of charge, to any person obtaining a copy of this software and associated documentation files (the "Software"), to deal in the Software without restriction, including without limitation the rights to use, copy, modify, merge, publish, distribute, sublicense, and/or sell copies of the Software, and to permit persons to whom the Software is furnished to do so, subject to the following conditions:

The above copyright notice and this permission notice shall be included in all copies or substantial portions of the Software.

THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT.

IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

This product uses the LZ4 compression library. LZ4 is © 2011–2016 Yann Collet and is governed by the following license:

All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met:

- Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer.

- Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the documentation and/or other materials provided with the distribution.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.