X-G-RST-DE Series

High precision motorized gimbals with built-in controllers and direct encoders

About This Series

Zaber's X-G-RST-DE series products are motorized two-axis rotation stage devices with built-in controllers and direct reading encoders for high accuracy motion. Rated for up to 15 kg load capacity centered about the elevation axis and 10 N⋅m of torque, they are ideal for high-load, high-precision, angular positioning in optics, telecom, scanning, and tracking applications.

These gimbals ship assembled, making them 'plug and play'. They are easy to set up and operate. A variety of standard crossmembers for both metric and imperial mounting are available: AP193M, AP193E, AP194M & AP194E; custom versions are also available. The adjustable height of the elevation assembly provides a versatile solution for centering different size payloads.

Zaber's X-RST-DE rotary stages with built-in controllers allow daisy-chaining power and communication. This means only one standard 48 V power supply is needed to power the gimbal. A single RS-232 or USB port from a computer can be used for convenient control of both axes of the system. The rotary stages are daisy-chained via slip ring offering tangle free cable management with unlimited rotation. Four additional signal wires are included through the slip ring, available for your convenience.

- An indexed knob provides convenient manual control.

- Control all units in the daisy-chain via serial port (with a locking X-SDC cable) or USB (with an X-USBDC cable).

- Daisy-chain additional units with a locking X-DC02 cable or X-DC06 cable. Power can also be shared in the chain.

- Integrated direct reading encoder, stepper motor controller and motor driver allows for easy-to-use control with stall detection.

- 200 step per revolution stepper motor, microstepped up to 256x to provide smooth and precise motion.

- Adjustable crossmember offset relative to elevation axis, from 0 mm to 175 mm in 12.5 mm increments. Note: Payload mount plates AP193 and AP194 are sold separately as accessories.

- High accuracy obtained with direct reading encoder with 0.2 arc sec resolution.

- Slip ring power and data interconnection allows continuous azimuth axis rotation and tangle free cable management.

- Aperture clearance on elevation axis offers convenient end user cable entry.

- High precision planar alignment between azimuth and elevation axes within 100 µm.

- Optional 4x 2 Amp signal wire connections available.

- Easy to mount; compatible with both metric and imperial breadboards.

Easy Set-Up

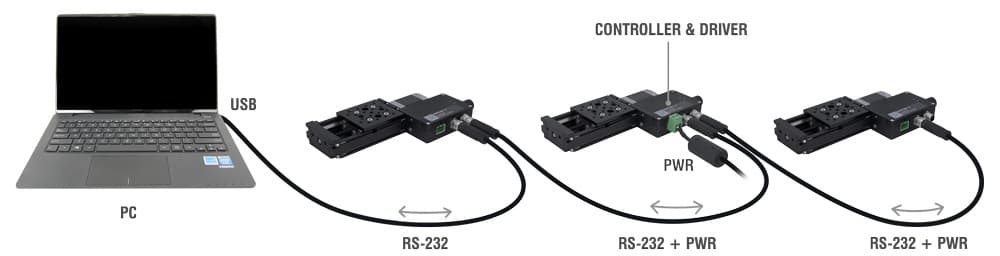

Zaber's devices can share both data and power through a daisy-chain, which reduces cabling and makes set-up as easy as 1, 2, 3:

- Connect the Zaber device to your computer via USB or RS-232 port.

- Connect the power supply to your Zaber device.

- Send instructions or automate your set-up using the Zaber Launcher.

For more details on daisy-chaining, read our technical article, "Daisy-chaining Data and Power to Reduce Cabling", or to determine which accessories you need for your system, try our Connection Guide Tool.

For additional information about setting up our devices, please visit our Support page, which includes our Getting Started Guide, Troubleshooting Guides, product user manuals, and other resources.