DMQ-AE Series User's Manual

Direct drive linear stages with built-in linear encoders

Disclaimer

Zaber’s products are not intended for use in any critical medical, aviation, or military applications or situations where a product's use or failure could cause personal injury, death, or damage to property. Zaber disclaims any warranty of fitness for a particular purpose. The user of this product agrees to Zaber's general terms and conditions of sale.

Precautions

Zaber's autodetect peripheral axes are designed to be used effortlessly with Zaber's line of autodetect controllers. The DMQ-AE includes onboard memory that allows Zaber's controllers to autodetect the model and set reasonable parameters. See the Protocol Manual for more information on how to modify the settings. Damage to the axis may result if the settings are not correct. To use your Zaber peripheral with a third-party controller, review the motor, sensor, and encoder specifications and pin-outs carefully.

Magnetic Flux Leakage

The DMQ-AE series of linear stages contains high-grade Neodymium-Iron-Boron (NdFeB) rare-earth magnets. A strong magnetic field is present at the surfaces of the device, which rapidly decays in strength with distance. Immediately adjacent to some surfaces the peak magnetic field is about 100 mT, decaying to 5 mT at a distance of 25 mm. This magnetic field may be strong enough to interfere with pacemakers or other magnetic-field-sensitive equipment placed sufficiently close to the device, and will gently attract nearby ferromagnetic objects. The accessory DMQ Flux Shield included with the DMQ-AE may be used to reduce the magnetic field for sensitive applications. Use of the DMQ Flux Shield or mounting to ferromagnetic surfaces will slightly reduce the force produced by the DMQ-AE.

Prolonged Operation at High Force and Temperature

In voice coil devices the maximum continuous force is limited by heat dissipation. The DMQ-AE is rated to produce a continuous force of 12 N under normal operating conditions, and peak forces of 15.5 N. This rating is tested at 20°C environment with the stage mounted to an aluminum surface. Under these conditions, the device can produce its continuous force indefinitely without suffering damage or exceeding a safe-to-touch temperature of 60°C.

Exceeding the continuous force rating for sustained periods of time (typically 1-5 minutes), or operation at high force outputs in non-standard conditions (such as an elevated-temperature environment, enclosed environment, or mounted to highly insulating surfaces) will result in a high surface temperature that may present a burn hazard. Operation under such conditions may also lead to a permanent reduction in device performance or accelerated failure.

If the DMQ-AE detects it is exceeding temperature limits, the controller will set the FD warning and disable the driver. Once the axis has cooled, send system reset to re-enable the driver. See the ASCII protocol manual for details about warning flags.

Servo Tuning

The DMQ-AE is a servo device, meaning that its performance is dependent on proper tuning of the servo parameters for the given load. The use of incorrect servo parameters may reduce the device's performance in operation. Incorrect tuning may also result in unstable operation, which can cause unexpected rapid motion of the device, leading to reduced device lifetime and user injury. When the operating load on the device is changed, the tuning parameters should be updated to match.

Backdrivability

The DMQ-AE does not have a brake, and can backdrive. When the device is un-powered or the force against the device exceeds the force that the device can exert (stall condition), the device will move in the direction that the external force is applied until the device reaches the end of its physical travel range. Be sure that harm cannot come to people or equipment if the device backdrives.

Bearing Lubrication

Short travel can cause an insufficient distribution of lubricant amongst the rolling elements of the bearing system for the DMQ-AE. For crossed-roller bearing guide types used in the DMQ-AE, short travel is equal to or less than twice the spacing of the rolling elements (typically 5-6 mm). If your application is considered short travel, it is recommended to occasionally drive the stage throughout its full travel range to maintain an even lubrication film over the entire guide surface.

Conventions used throughout this document

- Fixed width type indicates communication to and from a device. The

symbol indicates a carriage return, which can be achieved by pressing enter when using a terminal program.

symbol indicates a carriage return, which can be achieved by pressing enter when using a terminal program.

Device Overview

AutoDetect

Your DMQ-AE peripheral is equipped with AutoDetect, a feature that allows a Zaber controller to automatically configure its settings for the peripheral when it is connected.

Important: The controller should always be powered down before disconnecting or connecting your DMQ-AE peripheral.

Important: The controller should always be powered down before disconnecting or connecting your DMQ-AE peripheral.

To connect the peripheral to a controller:

- Power off the controller.

- Connect the DMQ-AE peripheral.

- Power on the controller.

- The controller will activate the peripheral shortly after it is powered on.

See the Zaber controller user manual for more details on peripheral activation and control.

Connectors

Recommended controller(s) for your DMQ-AE peripheral are provided in the product specifications. Zaber's controllers and peripherals are designed for ease of use when used together. Optimal settings for each peripheral are automatically detected by Zaber's controllers when the device is connected.

For reference, the pinout for the peripheral cable connectors is shown below:

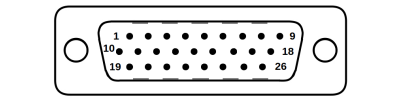

Pinout for D-sub 26 Connectors (peripherals)

Male High Density D-sub26 Connector |

Pin | Description | Pin | Description |

|---|---|---|---|---|

| 1 | AutoDetect Clock | 14 | N.C. | |

| 2 | AutoDetect Data | 15 | +5V | |

| 3 | N.C. | 16 | Ground | |

| 4 | N.C. | 17 | N.C. | |

| 5 | N.C. | 18 | N.C. | |

| 6 | N.C. | 19 | Differential Encoder Sin- | |

| 7 | Ground | 20 | Differential Encoder Cos- | |

| 8 | Motor A2 | 21 | Differential Encoder Index- | |

| 9 | Motor A1 | 22 | AutoDetect Presence | |

| 10 | Differential Encoder Sin+ | 23 | N.C. | |

| 11 | Differential Encoder Cos+ | 24 | N.C. | |

| 12 | Differential Encoder Index+ | 25 | N.C. | |

| 13 | N.C. | 26 | N.C. |

NOTE: All hall sensor signals (for limits or motor phase) are open collector and require a pull-up on the controller.

NOTE: All single-ended encoder inputs are non-isolated 5V TTL lines.

NOTE: All differential encoder signals are non-isolated, and must be terminated on the controller with 120 Ω. For -AE peripherals, these signals are sinusoidal with 1 V peak-to-peak differential levels and with the common mode between 1.5 V and 2.5 V.

Alternate Controllers

The DMQ-AE can be controlled by alternate controllers with appropriate motor and encoder input. Damage to the device due to incorrect wiring is not covered by warranty.

Motors & Encoders

For motor and encoder information see the DMQ-AE product page

Installation

The DMQ-AE can be operated by connecting to the controller/s recommended in the product specifications. Please review the controller's user manual as well.

Servo Tuning

This peripheral is a closed-loop positioning servo system. When not in force mode, it continuously monitors and corrects its position via the linear encoder. As with any servo system, the behaviour is dependent on the controller tuning. The DMQ-AE, when paired with a compatible Zaber controller, such as an X-MCC series Universal Motor Controller, will be appropriately tuned out of the box with settings that are optimized for regular use under a light load. However, as with any closed-loop feedback system, the device performance is load-dependent, and conditions significantly outside of the intended operating range have the potential for reduced performance or instability. Thus, if operation with large or unconventional dynamic loads is desired, or if the application demands specific performance characteristics, it may be necessary to tune the servo parameters. This may be conveniently done by using Zaber Launcher's Servo Tuner App, or Zaber Motion Library's ServoTuner API.

Tip: Because servo devices continuously monitor and correct position, it is necessary to specify how accurate and stable the final position must be at the end of the movement. Criteria required for the controller to report IDLE status after movement are specified using the cloop.settle.tolerance and cloop.settle.period settings. For applications requiring utmost precision, you may want to specify a smaller tolerance and longer period. Note that there is a direct, inverse relationship between settling time and cloop.settle.tolerance, and the controller may never report IDLE status if the tolerance is too small.

Tip: Because servo devices continuously monitor and correct position, it is necessary to specify how accurate and stable the final position must be at the end of the movement. Criteria required for the controller to report IDLE status after movement are specified using the cloop.settle.tolerance and cloop.settle.period settings. For applications requiring utmost precision, you may want to specify a smaller tolerance and longer period. Note that there is a direct, inverse relationship between settling time and cloop.settle.tolerance, and the controller may never report IDLE status if the tolerance is too small.

Trajectory Control and Behaviour

This section describes the behaviour of the axis trajectory when a movement command is issued.

Software Position Limits

The travel range of the axis is limited by the Minimum Position and Maximum Position settings. The factory settings for the axis are configured to match the physical travel range. If a customized range is desired, it can be changed by configuring the limit.min and limit.max settings to appropriate values. For the Current Position, query pos.

- Minimum Position

- When the Current Position is less than the Minimum Position value, the axis cannot move in the negative direction.

- Maximum Position

- When the Current Position is greater than the Maximum Position value, the axis cannot move in the positive direction.

Movement Speed

The movement speed of the axis depends on axis status and various speed settings. If the axis has not been initialized by the home command or by moving towards the home end of the axis, movement speed will be constrained to fail-safe values. The home status of the axis can be determined by reading the limit.home.triggered setting.

Movement speed of the axis is specified below:

- move vel

- The axis will move at the specified speed regardless of home status.

- Knob movement in Velocity Mode

- The axis will move at the specified speed regardless of home status.

- The speed is specified by the knob.speedprofile and knob.maxspeed settings.

- Other movement commands - when the axis has not been homed

- The axis will move at the slower of the maxspeed and limit.approach.maxspeed settings.

- Other movement commands - when the axis has been homed

- The axis will move at the speed specified by the maxspeed setting.

Warranty and Repair

For Zaber's policies on warranty and repair, please refer to the Ordering Policies.

Standard products

Standard products are any part numbers that do not contain the suffix ENG followed by a 4 digit number. Most, but not all, standard products are listed for sale on our website. All standard Zaber products are backed by a one-month satisfaction guarantee. If you are not satisfied with your purchase, we will refund your payment minus any shipping charges. Goods must be in brand new saleable condition with no marks. Zaber products are guaranteed for one year. During this period Zaber will repair any products with faults due to manufacturing defects, free of charge.

Custom products

Custom products are any part numbers containing the suffix ENG followed by a 4 digit number. Each of these products has been designed for a custom application for a particular customer. Custom products are guaranteed for one year, unless explicitly stated otherwise. During this period Zaber will repair any products with faults due to manufacturing defects, free of charge.

How to return products

Customers with devices in need of return or repair should contact Zaber to obtain an RMA form which must be filled out and sent back to us to receive an RMA number. The RMA form contains instructions for packing and returning the device. The specified RMA number must be included on the shipment to ensure timely processing.

Email Updates

If you would like to receive our periodic email newsletter including product updates and promotions.

Contact Information

Contact Zaber Technologies Inc by any of the following methods:

| Phone | 1-604-569-3780 (direct) 1-888-276-8033 (toll free in North America) |

|---|---|

| Fax | 1-604-648-8033 |

| #2 - 605 West Kent Ave. N., Vancouver, British Columbia, Canada, V6P 6T7 | |

| Web | www.zaber.com |

| Please visit our website for up to date email contact information. |

The original instructions for this product are available at https://www.zaber.com/manuals/DMQ-AE.

Appendix A: Default Settings

Please see the Zaber Support Page for default settings for this device.

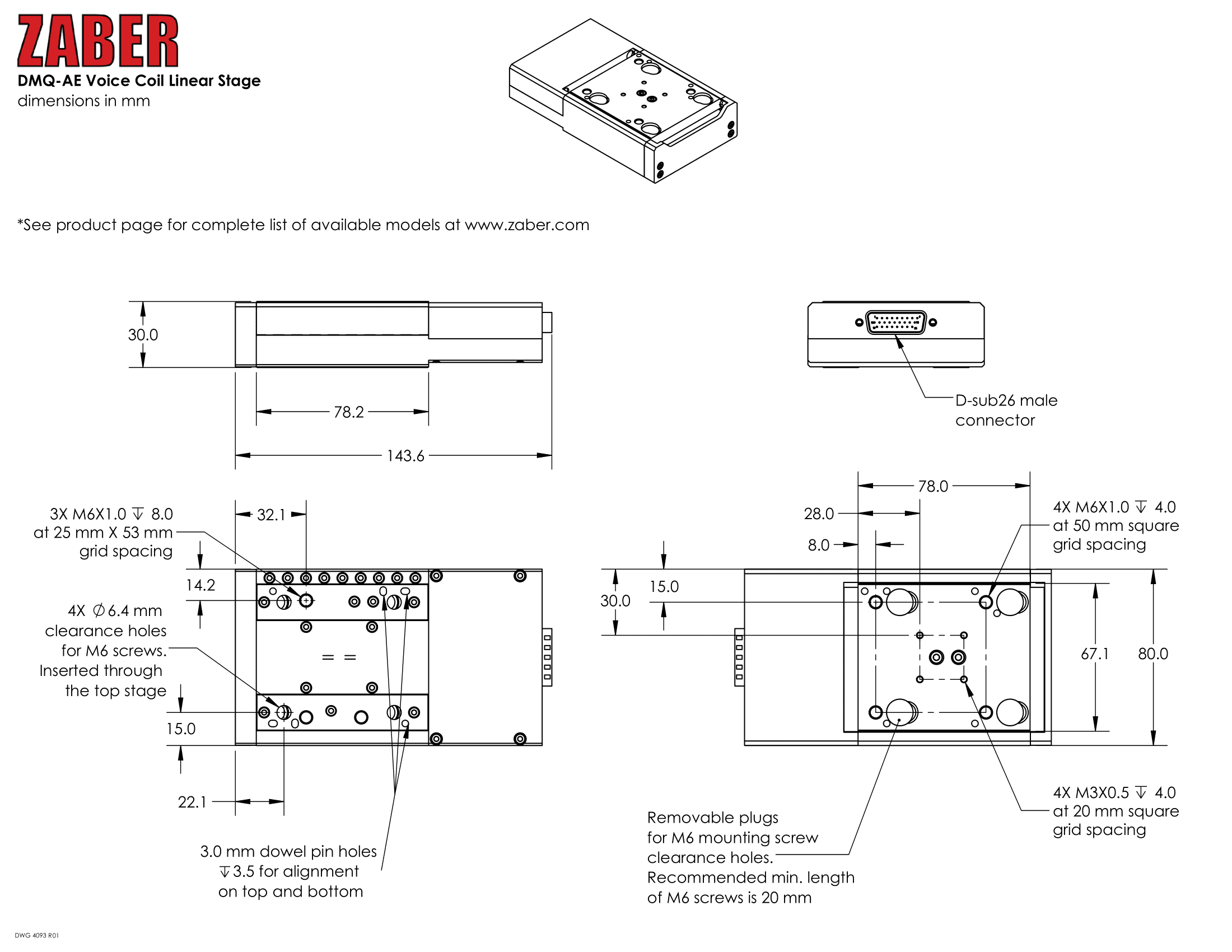

Product Drawing

Specifications

| Specification | Value | Alternate Unit |

|---|---|---|

| Built-in Controller | No | |

| Recommended Controller | X-MCC (48 V) Recommended | |

| AutoDetect | Yes | |

| Travel Range | 12 mm | 0.472" |

| Accuracy (unidirectional) | 4 µm | 0.000157" |

| Repeatability | < 0.5 µm | < 0.000020" |

| Minimum Incremental Move | 200 nm | |

| Maximum Acceleration | 245 m/s2 | 24.97 g |

| Maximum Speed | 1400 mm/s | 55.118"/s |

| Minimum Speed | 0.61 nm/s | |

| Speed Resolution | 0.61 nm/s | |

| Encoder Type | Linear analog encoder | |

| Encoder Count Size | 1 nm | |

| Peak Thrust | 26 N | 5.8 lb |

| Maximum Continuous Thrust | 12 N | 2.7 lb |

| Maximum Centered Load | 100 N | 22.4 lb |

| Maximum Moment (Pitch) | 120 N⋅cm | 169.9 oz⋅in |

| Maximum Moment (Roll) | 320 N⋅cm | 453.2 oz⋅in |

| Maximum Moment (Yaw) | 120 N⋅cm | 169.9 oz⋅in |

| Vertical Runout | < 6 µm | < 0.000236" |

| Horizontal Runout | < 5 µm | < 0.000197" |

| Typical Velocity Stability | ± 4.7% at 10 mm/s with a 0.38 kg payload | |

| Pitch | 0.01° | 0.174 mrad |

| Roll | 0.01° | 0.174 mrad |

| Yaw | 0.01° | 0.174 mrad |

| Stiffness in Pitch | 50 N⋅m/° | 349 µrad/N⋅m |

| Stiffness in Roll | 70 N⋅m/° | 249 µrad/N⋅m |

| Stiffness in Yaw | 85 N⋅m/° | 205 µrad/N⋅m |

| Motor Type | Voice Coil Linear Actuator | |

| Force Constant | 12.6 N/A | 2.8 lbs/A |

| Motor Connection | D-sub 26 | |

| Guide Type | Crossed-Roller Bearing | |

| Mechanical Drive System | Moving Coil, Direct Drive | |

| Limit or Home Sensing | Optical Index Mark | |

| Axes of Motion | 1 | |

| LED Indicators | Yes | |

| Mounting Interface | M6 and M3 threaded holes | |

| Moving Mass | 0.095 kg | 0.209 lbs |

| Operating Temperature Range | 0-50 °C | |

| CE Compliant | Yes | |

| Vacuum Compatible | No | |

| Weight | 0.8 kg | 1.764 lb |

Charts and Notes

Product Change Notices

Click here to view the current product change notices and subscribe to future change notifications.