Scope

This manual defines Zaber’s ASCII protocol for all products with firmware versions 7.46 and below. Not all commands or settings are supported by all products. See the product-specific protocol manual for which commands and settings a product supports.

This manual defines Zaber’s ASCII protocol and the device settings and commands for the GENERIC PRODUCT running firmware version 7.46. Other products or firmware versions may support other commands or settings; see a product’s specific protocol manual for the commands and settings it supports.

If your device uses Firmware 6, refer to the Firmware 6 ASCII Protocol Manual. See here for instructions on how to tell which version your device uses.

Conventions

Conventions used throughout this document:

Fixed widthtype indicates ASCII characters communicated to and from a device.- The

↵symbol indicates a newline. When sending a command to a device,↵can be any combination of the Carriage Return (CR,‘\r’, ASCII code 13) and/or Line Feed (LF,‘\n’, ASCII code 10) characters. In responses from a device,↵includes both the Carriage Return and Line Feed characters. - When describing command parameters:

- Square brackets around a parameter indicate it is optional, e.g., [axis].

- Three periods following a parameter indicate that the parameter can be included more than once in a single command, e.g., axis

.... - An italicized parameter with a

<prefix and>suffix must be replaced with data, typically a number, when sending the command, e.g., <value>. - A pipe separating multiple parameters indicates that one of the listed parameters should be provided, e.g., abs|rel.

- Parameters enclosed in parentheses are grouped together with respect to operators, e.g., <channel>|(port <action>) means only <channel> or port <action> are valid; <channel> <action> is invalid.

Physical Units

Many of the setting values and command parameters described in this document relate to physical units, such as distance, voltage, and time. When a setting value is expressed in a real-world metric unit or in a scaled version of a unit, the units are described explicitly (such as a voltage specified in units of volts, or a current specified in 20 mA increments). In other cases, the value is unitless and some scaling factor is required to convert to a practical unit. Unitless values may be referred to in this document as the ‘data’ value.

In general, the documentation of each command or setting describes how to convert the relevant data values to real-world units. An exception is for values involving physical distances or positions (including speed/velocity and acceleration/deceleration), which are described here. This section is referenced whenever they’re used in a command or setting.

Converting data values involving distance or position to real-world values requires a device-specific conversion factor, which is listed in the "Specifications" section of the device’s User Manual.

For stepper motors, this conversion factor is called "Microstep Size". The value in the User Manual assumes the resolution setting is at the default value. If you have modified the resolution value, the Microstep Size can be converted:

The default resolution is available at Zaber Support - Device Settings.

For linear motor or voice coil products, this conversion factor is called "Encoder Count Size".

Position

For stepper motor products, all position and distance data values are in units of stepper motor microsteps. The conversion from distance or position data values to real-world units is given by:

For linear motor or voice coil products, all position and distance data values are in units of encoder counts. The conversion from distance or position data values to real-world units is given by:

Velocity

For stepper motor products, the conversion from velocity or speed data values to real-world units is given by:

For linear motor or voice coil products, the conversion from velocity or speed data values to real-world units is given by:

Acceleration

For stepper motor products, the conversion from acceleration or deceleration data values to real-world units is given by:

For linear motor or voice coil products, the conversion from acceleration or deceleration data values to real-world units is given by:

Quick Start

Connecting

Zaber devices support connecting to user equipment over standard serial connections using a human-readable, text-based protocol - Zaber’s ASCII protocol. This allows these devices to interface with a variety of equipment and software, including:

- Zaber Launcher

- Zaber Motion Library

- Zaber Console

- Terminal Emulators

- User programs

- PLCs

- Automation and Instrumentation packages

Zaber devices can be up and running in a matter of minutes, no matter what environment is being used.

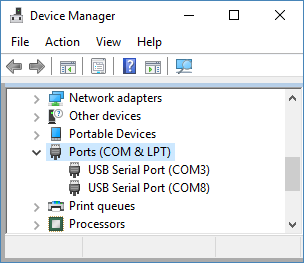

X-Series devices typically communicate over RS-232 at 9600 or 115200 baud, with 8 bits, 1 stop bit and no parity, however please refer to the RS-232 Communications section of the device-specific User Manual for the correct settings. Characters are not echoed by the device, so if a terminal emulator is being used, it is advisable to turn on local echo.

Talking to Zaber Devices

Zaber devices listen for commands sent to them over a serial port and then immediately respond with a reply. Commands always begin with a / and end with a newline. Some commands take parameters, which are separated by spaces. Two example commands are:

/1 warnings↵

/1 system reset↵Replies begin with a @, end with a newline, and have several space-delimited parameters in between. For example, the most common reply is:

@01 0 OK IDLE -- 0This can be broken down into:

@ A reply.

01 The address of the device sending the reply

0 The reply scope: 0 for the device or all axes, 1 onwards for an individual axis

OK The command succeeded.

IDLE The device isn’t moving (or BUSY if it is moving).

-- No faults or warnings are active.

0 The return value, typically 0 Devices can also send two other types of messages: alerts, which start with !; and info, which start with #.

Talking to an Individual Device

If there is more than one device in a chain, sending the command /move abs 10000 will move all devices in the chain at once and return multiple responses. While this is a handy feature for initial setup, general use requires a way to instruct only an individual device to move.

Devices can be addressed by including their device number before the command. For example, the following command instructs only device 1 to move:

/1 move abs 10000↵

@01 0 OK BUSY -- 0The valid device addresses are from 1 to 99 inclusive and can include a leading 0 for devices 1 to 9. For example, both 01 and 1 refer to device 1.

Talking to an Individual Axis

On multi-axis devices, commands of the form /command or /# command affect all axes of the device. In order to send a command to a single axis, provide an axis number after the device number.

Example: Moving a single axis

The following command instructs axis 1 on device 2 to move to position 10,000:

/2 1 move abs 10000↵

@02 1 OK BUSY -- 0Note that the response scope is 1, indicating that the information in the reply applies to axis 1.

Example: Turning on a single lamp

The following command instructs lamp axis 1 on device 2 to turn on:

/2 1 lamp on↵

@02 1 OK BUSY -- 0Note that the response scope is 1, indicating that the information in the reply applies to axis 1.

Talking to Multiple Axes

On multi-axis devices, commands of the form /command or /# command affect all axes of the device.

The firmware processes an axis-scope command addressed to multiple axes in two steps.

First, it selects the axes which support the command. If no axes support the command, the command will be rejected with the reason BADCOMMAND.

Then, if at least one axis supports the command, firmware will validate the command on all the supported axes. The command will only execute if validation succeeds on all of these axes; if validation fails on any single axis, the command will be rejected with a reason other than BADCOMMAND.

Settings that are not supported on an axis will return NA when read with a get command.

- The axis is in unused mode

- The command or setting may pertain to a feature that requires hardware that the axis does not have. For example, settings to configure an encoder are not supported on axes with no encoder.

- A set command is trying to modify a read-only setting.

BADCOMMAND, the command is not supported on that axis. Example: Reading the position of multiple axes

Read the position of all axes on a 3-axis controller:

/1 get pos↵

@01 0 OK IDLE -- 12345 NA 0- The peripheral on axis 1 is at position 12,345.

- Axis 2 does not support the command, so the pos value returned is

NA. This likely indicates it is in unused mode. - The peripheral on axis 3 is at position 0.

Note that the response scope is 0, indicating that the information in the reply applies to all axes.

Example: Setting the maximum speed on multiple axes at once

Set maxspeed to 100,000 on all axes of a 3-axis controller:

/1 set maxspeed 100000↵

@01 0 OK IDLE -- 0Now verify the result by reading maxspeed on all axes:

/1 get maxspeed↵

@01 0 OK IDLE -- 10000 NA 100000- Axes 1 and 3 now have maxspeed set to 100,000.

- Axis 2 returned

NA, indicating that the maxspeed setting is not supported on that axis.

Example: Reading a setting on multiple axes

Read the maximum position of all axes on a 2-axis device:

/1 get limit.max↵

@01 0 OK IDLE -- 640000 768000- The maximum position of axis 1 is 640,000.

- The maximum position of axis 2 is 768,000.

Note that the response scope is 0, indicating that the information in the reply applies to all axes.

Example: Reading the maximum current of all lamp axes

Read the maximum current of each lamp on an X-LCA:

/1 get lamp.current.max↵

@01 0 OK IDLE -- 1.000 NA 0.8000 NA- The lamp peripheral on axis 1 has a maximum current of 1 A.

- Axis 2 is unused, so the value returned is

NA. - The lamp peripheral on axis 3 has a maximum current of 0.8 A.

- Axis 4 is unused, so the value returned is

NA.

Note that the response scope is 0, indicating that the information in the reply applies to all axes.

Making it Move

It is recommended that the first movement command sent to a device after it is connected and powered is the home command. The device will move to the home limit sensor and establish a reference position:

/home↵

@01 0 OK BUSY WR 0If the device hasn’t been homed, motion commands may not work as expected. The controller’s position limits will not match the physical limits, absolute movements will not move to expected positions, and relative movements the device is capable of may be rejected for being outside the travel range. Replies from the device will include the No Reference Position (WR) flag:

/move rel 10000↵

@01 0 RJ IDLE WR BADDATAOnce the device has been homed, make the device move by sending a move command. For example, to move a distance of 10,000 forward from the current position:

/move rel 10000↵

@01 0 OK BUSY -- 0To move to the absolute position 10,000, measured from the home position, regardless of the current position:

/move abs 10000↵

@01 0 OK BUSY -- 0See the Physical Units section for information about unit conversions.

Changing a Device Setting

All of the device settings are read and modified using the get and set commands. For example, to query the device maxspeed:

/get maxspeed↵

@01 0 OK IDLE -- 153600The maximum speed setting is currently 153,600.

See the Physical Units section for information about unit conversions.

On a multi-axis device, sending an axis-scope command without specifying an axis returns a value for each of the axes. For example:

/get maxspeed↵

@01 0 OK IDLE -- 153600 153600To set the maximum speed, for example, to be twice what was read:

/set maxspeed 307200↵

@01 0 OK IDLE -- 0On a multi-axis device, the command above sets the maximum speed for all axes.

Message Format

The ASCII protocol uses a command-reply model, such that:

- The user must initiate all communication by sending a device a command.

- Unless explicitly disabled, a device always responds with one reply immediately after a command has been received (see the Message IDs section for how to disable replies). Select commands will return additional Info messages.

- Unless explicitly enabled, a device never sends a message unless in response to a command (see Alerts for more information).

The content of the message is space-delimited, with consecutive spaces being treated as a single space. There is only one command or response per message. Sending multiple commands in a single message is not supported.

Reserved Characters

The following characters are reserved and their use is restricted:

-

/,@,#, and!indicate the message type and must be the first byte of a message. - Carriage Return (CR,

‘\r’, ASCII code 13), Line Feed (LF,‘\n’, ASCII code 10), or any combination thereof, indicate a newline (collectively represented as↵) and the end of a message. All newline characters must be the last bytes of a message. -

:indicates the start of a message checksum and must be followed by a two-byte checksum and↵. See Checksums for more details. -

\indicates a line continuation for firmware versions 7.12 and above and must only appear immediately prior to↵or the:of a message checksum. It may appear in replies or info messages. In firmware versions 7.26 and above it may also appear in command messages. See Line Continuation for more details. -

\is reserved in firmware versions 7.11 and below and may not be present anywhere in a message. - Bytes 128 to 255 are reserved and may not be present anywhere in a message.

Any message that includes these characters in positions other than those specified above is malformed. If a device receives a malformed command it may not respond, respond with the reason BADCOMMAND, or interpret the command in unexpected ways. For example, including ! as an argument to a command will not elicit a reply:

/tools echo hi!↵Similarly, including newline characters, ↵, anywhere but the last bytes of a command will truncate the message, producing an unexpected reply:

/tools echo hello↵world↵

@01 0 OK IDLE -- helloCommands

Users send commands to one or more devices, which always and immediately respond with a reply. See the Command Reference section for all the available commands. A command instructs the device to perform an operation. An example of a typical command message and associated fields is:

╭────────────────────── /

│╭───────────────────── [n]

││ ╭─────────────────── [a]

││ │ ╭───────────────── [i]

││ │ │ ╭────────────── x...

││ │ │ │ ╭────── [y...]

││ │ │ │ │ ╭─ [\][:CC]

││ │ │ ╭┴─╮ ╭───┴───╮├─ ff

/1 1 1 move abs 10000↵/-

Message Type

Size: 1 byte

The message type for a command is always

/.This field and the footer are the only required fields; all others are optional.

n-

Device Address

Size: 1+ bytes

The address indicates which device number should perform the command. The address is optional: if it is not included, or set to 0, all devices on the chain execute the command. Device addresses range from 1 to 99 inclusive.

Examples of acceptable addresses are:

0, 00, 1, 01, 000001, 76, 99, 0x00, 0x01, 0x5A, 0x5aInvalid addresses include:

100, -1, 0x65The addresses are out of range and while the message may be valid, no device will respond.

a-

Axis Number

Size: 1+ bytes

The axis number indicates which axis within a device should perform the command. The axis number is optional: if it is not included, or set to 0, the command is executed by all axes of the device. If it is included, the Device Address is then also required. Axis numbers range from 1 to 9 inclusive.

The axis number is further restricted by the number of axes that are actually present on the device. The device will reject commands with an axis number higher than what the device supports with the reason

BADAXIS.Examples of acceptable axis numbers are:

0, 00, 1, 01, 000001, 0x00, 0x01Invalid axis numbers include:

76, 99, 0xA, 0x0a, -1, 0x65These axis numbers are out of range, and the command will be rejected.

i-

Message ID

Size: 1+ bytes

The message ID is an optional field that can be included in any command, and causes responses (including reply and info responses) to the command to include the same message ID. If it is included, the Axis Number and Device Address are then also required.

For more information about message IDs, see Message IDs.

x...-

Command

Size: Variable

The command message data contains the command information. The contents are space-delimited.

The Command Reference covers the available commands.

y...-

Command Parameters

Size: Variable

This message data contains command parameters and data. The contents are space-delimited and case-sensitive. Any numerical values in the message data can either be in decimal format or in hexadecimal and prefixed with

0x.Negative values are prefixed with ‘

-’; positive values may optionally be prefixed with ‘+’.The Command Reference covers the contents of the parameters field for the available commands.

\-

Line Continuation

Size: 1 byte

Indicates that the command is not complete and the controller should expect subsequent packets containing the rest of the command. See Line Continuation for more details.

Introduced in 7.26

:CC-

Message Checksum

Size: 3 bytes.

The message checksum is an optional parameter that, when provided, causes a device to reject a message that has been corrupted during transmission.

For more information about checksums, see Checksums.

ff-

Message Footer

Size: 1 - 2 bytes

The footer indicates end-of-message. For convenience, the device accepts any ASCII combination of carriage return (CR,

\r) and/or line feed (LF,\n) as a message footer. In a terminal emulator, this is included when the command is sent by pressing enter or return.

Smallest Command

The smallest valid command is /↵, which generates a response from all devices in the chain:

/↵

@01 0 OK IDLE -- 0

@03 0 OK IDLE -- 0

@02 0 OK IDLE -- 0This can be used as a quick way to check the statuses of all devices and that they are communicating as expected.

Largest Command

The maximum command packet size is comm.packet.size.max comm.packet.size.max 80 80 (comm.packet.size.max) characters, including the / and ↵. Devices do not respond to command packets longer than this. In firmware versions 7.26 and above, Line Continuation can be used to send a larger command by splitting it into multiple packets.

Replies

The device sends a reply as soon as it has received a command and determined if it should respond. An example of a typical response message and associated fields is:

╭────────────────────── @

│╭───────────────────── n

││ ╭────────────────── a

││ │ ╭──────────────── [i]

││ │ │ ╭───────────── fl

││ │ │ │ ╭───────── s

││ │ │ │ │ ╭───── w

││ │ │ │ │ │ ╭── x

││ │ │ │ │ │ │╭─ [\][:CC]

││ │ │ │ ╭┴─╮ │ │├─ ff

@01 0 01 OK IDLE -- 0↵@-

Message Type

Size: 1 byte

The message type for a reply is always

@. n-

Device Address

Size: 2 bytes

The address indicates the address of the device sending the message, and is always formatted as two digits.

a-

Axis Number

Size: 1 byte

The axis number limits the scope of the reply, and has a value in the range of 0 to 9. An axis number between 1 and 9 indicates the reply applies specifically to that axis. An axis number of 0 indicates that the reply applies to the whole device and all axes on it.

i-

Message ID

Size: 2 bytes

The message ID of the command that elicited the reply. Omitted if the command had no message ID.

For more information about message IDs, see Message IDs.

fl-

Reply Flag

Size: 2 bytes

The reply flag indicates if the message was accepted or rejected and has one the following values:

OKThe command was valid and accepted by the device.

RJ-

The command was rejected. The data field of the message will contain one of the following reasons:

AGAINThe device cannot process the command right now. Send the command again. This response is only in replies to stream or pvt commands.

AXISONLY-

On a multi-axis device, the command must be addressed to a particular axis, but the axis number was

0or omitted. BADAXISThe command’s axis number was greater than the number of axes available.

BADCOMMANDThe command or setting was incorrect or invalid.

BADDATAThe command’s data was incorrect or out of range.

BADMESSAGEIDThe command included a message ID, but the ID was not either

--or a number from 0 to 99.BADSPLITThe command was split into multiple packets in an incorrect way. Possible causes include the parts having different axis numbers or message IDs, an incorrect packet counter value, incorrect positioning of

\characters, or the use of the line continuation feature in a renumber command. See Line Continuation for more details.BRAKECLOSED-

One of the specified axes has a closed brake so cannot move. Open the brake using the brake.mode setting.

DEVICEONLYAn axis number was provided to a device-scope command.

DRIVERDISABLED-

One of the drivers is disabled because the driver is or was in an over-temperature, over-voltage, or over-current condition. Alternatively, it is possible that the device’s emergency stop input was activated or that the user disabled the driver with the driver disable command. See Warning Flags to determine the underlying cause. This rejection reason persists until the driver is successfully re-enabled with the driver enable command.

FULL-

The device cannot allocate more memory for information related to the command. See the documentation for the command that prompted this response for details of this rejection.

INACTIVE-

The command failed to execute because the axis is inactive. See Peripheral Inactive (

FZ) for more information. INVALIDLIMITS-

The process output cannot be turned on because voltage limits are not set correctly. See process on for more information.

LOCKSTEPAn axis cannot be parked, unparked, or moved using normal motion commands because it is part of a lockstep group. Use lockstep commands instead or disable the lockstep group first.

LONGWORDA word in a message was longer than comm.word.size.max characters.

NOACCESSThe command or setting is not available at the current access level.

NOTSINThe axis is not currently moving in response to a move sin command, so it cannot be stopped with the move sin stop command.

NOTSUPPORTED-

The axis cannot be activated because the connected peripheral is not supported by this version of firmware.

See Peripheral Not Supported (

FN) for more information. OVERDRIVELIMIT-

The axis cannot execute motion requests because it exceeded its overdrive energy limit and has entered the recovery state.

The axis cannot execute motion requests because it has not yet cooled sufficiently since exceeding its overdrive energy limit.

See Overdrive Limit Exceeded (

FR) for more information.The axis cannot execute motion requests because it exceeded its overdrive energy limit and has entered the recovery state.

PARKED-

The device cannot move because it is currently parked.

Use the tools parking unpark command to unpark the device.

PROCESSON-

The setting value cannot be changed because the process output is currently turned on. Use process off to turn the output off before changing the setting.

REMOTE-

The command cannot be executed because the device is in EtherCAT Remote Mode. See comm.ethercat.remote for more details.

REMOTEANDENABLED-

The command cannot be executed because the device is in EtherCAT Remote Mode and the axis is in the Operation Enabled CiA402 state. See comm.ethercat.remote for more details.

STATUSBUSY-

The device cannot execute the command because it is currently busy. For example, the command might require that the axis have the

IDLEstatus when it is insteadBUSY, or some other resource required for the command is already in use. SYSTEMERROR-

The device failed to execute the command due to a system failure. Use the system errors command to review errors.

TWISTED-

The device failed to execute a stream or pvt command on a lockstep group because the axes in the group are twisted beyond the allowable threshold and cannot correct for the twist. Send a lockstep move command to automatically untwist the axes before retrying the stream or pvt command. See the lockstep commands section for more information about twisting.

s-

Status

Size: 4 bytes

On devices that control motion axes, the device status is

BUSYwhen the axis is moving andIDLEotherwise. All motion commands, including stop, put the axis into theBUSYstate while they are being executed. During streamed motion, stream wait commands are considered to be busy, not idle. If the reply message applies to the whole device, the status isBUSYif any axis is busy andIDLEif all axes are idle.On devices that control lamps, the device status is always

IDLE. w-

Warning Flag

Size: 2 bytes

The warning flag is the highest priority warning currently active for the device or axis, or

--when there are no warnings. For the list of warning flags, see Warning Flags. x...-

Data

Size: 1+ bytes

The contents and format of the data vary depending on the command the reply relates to. The data is

0for commands that don’t return specific information. \-

Line Continuation

Size: 1 byte

Indicates that the message cannot fit within the comm.packet.size.max comm.packet.size.max 80 80 (comm.packet.size.max) character limit of an ASCII packet and is incomplete. The remainder of the message will be sent in subsequent Info packet(s). See Line Continuation for more details.

Introduced in 7.12

:CC-

Message Checksum

Size: 3 bytes

The comm.checksum setting determines whether a reply includes a checksum.

For more information about checksums, see Checksums.

ff-

Message Footer

Size: 2 bytes

The message footer is always composed of a CR-LF combination (

\r\n).

Replies on Multi-axis Devices

For replies with an axis number of 0, the status and warning flags apply to the whole device. If any axis on the device is moving, then the reply status is BUSY. Similarly the warning flags show the highest priority warning across all axes.

For replies with an axis number of 1 or above, the status and warning flags only apply to the axis indicated.

Warning Flags

Each reply message includes a warning flag, indicating whether any device fault or warning is active. If more than one condition is active, it shows the one with highest priority.

- Fault

-

Flags in this category indicate an event that has immediate consequences to the behaviour of the device. As a result, the device may have deviated from its trajectory or stopped.

- Warning

-

Flags in this category indicate that continued operation may lead to unexpected behaviour.

- Note

-

Flags in this category indicate that an event should be noted by the user before continued operation, but is part of normal device operation.

The warning flags are defined as follows, with the highest priority first:

FF-

Fault - Critical System Error

The device has experienced a critical system error. This should not occur during normal operation. Please contact Zaber Support with the response from system errors if this occurs.

FN-

Fault - Peripheral Not Supported

The connected peripheral is not supported by this version of firmware.

We recommend upgrading the controller to the latest firmware version (see Firmware Upgrades). To read the currently installed firmware version, consult the version setting. To look up which firmware versions support your peripheral, see Device Settings.

FZ-

Fault - Peripheral Inactive

The peripheral is inactive.

Until the peripheral is reactivated, all motion commands will be rejected.

Until the peripheral is reactivated, all lamp commands will be rejected.

On autodetect peripherals, this flag indicates one of the following:- One or more of the peripheral’s cables is not fully plugged in. Depending upon the order in which the cables are reconnected, activation may not happen automatically. In this case, send the activate command to manually activate the peripheral after reconnecting the cables.

- The peripheral that is plugged in is different from the peripheral for which the controller is currently configured. To rectify this, either plug in the correct peripheral, or send activate to accept the new configuration.

On peripherals without the autodetect feature, this flag indicates one of the following:- The peripheral.id setting is not correct. Check that it matches the value on the label of the peripheral.

- The peripheral is not plugged in.

- The peripheral is properly configured, but needs to be activated. Send the activate command.

This warning may be present at startup while the controller checks for the presence of autodetect peripherals.

See the peripheral settings section for more detailed information about peripheral configuration and activation.

FH-

Fault - Hardware Emergency Stop Driver Disabled

The device has disabled the driver in response to a hardware emergency stop signal.

This warning persists until the driver returns to normal operating conditions, the hardware emergency stop is deactivated, and the user re-enables the driver with a driver enable command.

FV-

Fault - Overvoltage or Undervoltage Driver Disabled

The device has disabled the driver in response to the driver voltage being outside the normal operating range. This can occur if:- a stall has occurred

- the motor is backdriven

- there is damage to the driver hardware

- there is a problem with the power supply

- the supply voltage is below the level needed to open the brake.

This warning persists until the driver voltage returns to normal operating conditions, and the user re-enables the driver with a driver enable command.

This warning may appear briefly at power-up.

FO-

Fault - Driver Disabled

The device has disabled the driver. There are several cases in which case this warning flag can appear:- This warning will appear after the user has sent a driver disable command. In this case, it will persist until the user re-enables the driver with a driver enable command.

- This warning may appear at power-up or after a reset, while the device starts up. On controllers, this warning may also appear after a peripheral is plugged in or activated, while the controller waits for the peripheral to power up. Once the device is ready, if driver.enable.mode is set to 1, the driver will be automatically enabled and the warning flag will be cleared.

- If driver.enable.mode is set to 0, this warning will appear after a peripheral is unplugged from a controller. It will persist until the user re-enables the driver with a driver enable command.

- It may also appear while executing certain commands or setting changes that require disabling the driver. If the driver was previously enabled, the driver will automatically be re-enabled once the device is ready.

- On brake products, this warning will occur if a non-recovered stall or displacement occurs. In this case, either the Stalled Stalled Stalled and Stopped (

FS) or Displaced When Stationary (WM) warning flag will also be raised. The Driver Disabled (FO) will persist until the user re-enables the driver with a driver enable command. - On EtherCAT products, this warning will appear whenever the device is in the Switch On Disabled, Ready To Switch On, Switched On, or Not Ready To Switch On CiA402 states. Several fault conditions can also disable the driver and cause this warning to appear when the device is in the Fault state. The driver will remain disabled until the user re-enables the driver with a driver enable command or via the CANopen Controlword (0x6040) object. See the CANopen Protocol Manual for more details.

Introduced in 7.11

FC-

Fault - Current Inrush Error

The device has disabled the driver due to an excessive inrush of current from the power supply. This may occur due to a problem with the driver or motor or load, motor, or load, or in rare cases during normal operation if the device attempts to draw more than system.current.max from its supply. It may also occur when power supplies are connected to or disconnected from a controller supporting multiple power supplies or devices in a daisy-chain.

This warning persists until the user re-enables the driver with a driver enable command.

In firmware versions 7.37 and below, this warning may appear at power-up or after a reset, while the device starts up. Once the device is ready, the driver is automatically enabled and the warning flag is cleared.

Introduced in 7.11

FM-

Fault - Motor Temperature Error

The device has disabled the driver due to an overheating motor.

This warning persists until the motor temperature returns to normal operating conditions and the user re-enables the driver with a driver enable command.

On a controller, this flag may appear when the peripheral is unplugged. It will be cleared when the peripheral is activated. See the peripheral settings section for more information on activating peripherals.

Warning: Continually driving the motor at power levels sufficient to repeatedly trigger this fault may permanently damage the motor.Introduced in 7.11

FD-

Fault - Driver Temperature/Current Error Driver Temperature/Current Error Driver Disabled

Called Driver Disabled in firmware versions 7.10 and below.

The device has disabled the driver due to an overheating driver or an over-current condition.

In firmware versions 7.10 and below, this also indicates that the device has disabled the driver in response to a driver disable command.

On products with encoders with firmware versions 7.08, 7.09, or 7.10, this warning may also appear when the device powers up, while the controller waits for the encoder to power up. Once the encoder is ready, the driver is automatically enabled and the warning flag is cleared.

This warning persists until the driver temperature and current return to normal operating conditions and the user re-enables the driver with a driver enable command.

FQ-

Fault - Encoder Error

The encoder-measured position may be unreliable. The encoder has encountered a read error due to poor sensor alignment, vibration, dirt or other environmental conditions. Reset the encoder reference position by sending system reset followed by a home operation.

On a controller, if the peripheral ID of a product is set but the peripheral is unplugged, this flag may appear. It will be cleared when the peripheral is activated. See the peripheral settings section for more information on activating peripherals.

On EtherCAT devices, the device will disable the driver and set the Driver Disabled (

FO) flag.This warning persists until acknowledged and cleared by the user with the warnings clear command.

Please contact Zaber Support if this error persists.

FI-

Fault - Index Error

The encoder has encountered a problem with the index mark and the home position may be unreliable. This could be due to poor sensor alignment, vibration, dirt, or other environmental conditions. A home operation is recommended to reset the encoder reference position.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

Please contact Zaber Support if this error persists.

FA-

Fault - Analog Encoder Sync Error

The encoder-measured position may be unreliable due to a problem interpolating the encoder signals. This could be due to poor sensor alignment, dirt, or other environmental conditions. Reset the encoder reference position by sending system reset followed by a home operation.

On a controller, if the peripheral ID of a product is set but the peripheral is unplugged, this flag may appear. It will be cleared when the peripheral is activated. See the peripheral settings section for more information on activating peripherals.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

Please contact Zaber Support if this error persists.

FR-

Fault - Overdrive Limit Exceeded

The axis exceeded its overdrive energy limit and has entered the recovery state. The axis has stopped or is in the process of stopping.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

The axis exceeded its overdrive energy limit and either has stopped or is in the process of stopping. The driver has temporarily restricted its current output to driver.current.continuous, and will temporarily reject motion commands. The axis driver will begin accepting motion requests and allowing overdrive currents after driver.i2t.measured and motor.i2t.measured have both fallen below 100 %.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

See the driver settings section for more details on continuous and overdrive current limits.

The axis exceeded its overdrive energy limit and has entered the recovery state. The axis has stopped or is in the process of stopping.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

Introduced in 7.28

FS-

Fault - Stalled Stalled Stalled and Stopped

Called Stalled and Stopped in firmware versions 7.26 and below.

The axis detected a stall. The action specified by cloop.stall.action has begun, and as a result, the axis may have stopped. In firmware versions 7.26 and below, the axis has immediately stopped. The requested movement was not completed.

On EtherCAT devices, after the stall action has completed (cloop.stall.action), the device will disable the driver and set the Driver Disabled (

FO) flag.On brake products, after the stall action has completed (cloop.stall.action), the device will disable the driver and set the Driver Disabled (

FO) flag.This warning persists until acknowledged and cleared by the user with the warnings clear command.

FB-

Fault - Stream/PVT Sequence Bounds Error Stream Bounds Error Stream/PVT Sequence Bounds Error

The device could not execute a previously sent stream or pvt movement because it failed a precondition (e.g., motion exceeds device bounds, calls nested too deeply), or a PVT sequence ended with non-zero velocity, causing it to deviate from the prescribed path.

Obtain the error reason with the stream info or pvt info command.

This warning persists until acknowledged and cleared by the user with the warnings clear command or until the stream or PVT sequence is disabled with the stream setup disable or pvt setup disable command. Until the warning is cleared, no further streamed motions or PVT points can be sent to the failed stream or PVT sequence.

FP-

Fault - Interpolated Path Deviation

The device has terminated streamed or sinusoidal motion because it slipped and thus deviated from the requested path.

See cloop.enable for more information on slips.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

This warning has been removed in firmware versions 7.09 and above.

FE-

Fault - Limit Error

A limit sensor is faulty, could not be found, or was found unexpectedly; or the axis would need to move outside of its limits to achieve the commanded motion

This warning persists until acknowledged and cleared by the user with the warnings clear command.

On a controller, this flag may appear when the peripheral is unplugged. It will be cleared when the peripheral is activated. See the peripheral settings section for more information on activating peripherals.

If the axis is part of a lockstep group, excessive twist may have prevented the axis from reaching the limit sensor.

While detecting the installed filter holder the device failed to find the away sensor or found it in an unexpected position.

While homing or spontaneously encountering a limit sensor, this flag may appear if the offset position dictated by limit.home.offset is outside the range limit.min to limit.max.

In firmware versions 7.37 and above, this flag may appear if the sensor position the tools gotolimit command tries to write to limit.min or limit.max is beyond the valid limits (-1,000,000,000 to 1,000,000,000).

This flag may appear during a move track command if the control loop needed to drive the axis beyond the valid limits or if the analog input signal became invalid.

This flag may appear during a move scan track once command if the command completed the scanning stage without locating a valid analog signal or if the resulting position after moving motion.tracking.scan.offset would be outside the valid travel range for the command.

FT-

Fault - Excessive Twist

Twist in the lockstep group exceeded the allowable tolerance setting or one of the axes has stalled (regardless of the twist tolerance), and movement has stopped.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

WL-

Warning - Unexpected Limit Trigger

A movement operation did not complete due to a triggered limit sensor. This flag is set if a limit sensor interrupts a movement operation and the No Reference Position (

WR) warning flag is not present. This may be an indication that the axis has slipped or one of limit.min and limit.max is incorrect.This warning persists until acknowledged and cleared by the user with the warnings clear command.

On a controller, this flag may appear when the peripheral is unplugged. It will be cleared when the peripheral is activated. See the peripheral settings section for more information on activating peripherals.

WV-

Warning - Voltage Out of Range

The supply voltage is outside the recommended operating range of the device. Damage to the device could occur if not remedied.

This warning persists until the condition is remedied.

WT-

Warning - Temperature High

The internal temperature of the controller or lamp has exceeded the recommended limit for the device.

This warning persists until the over-temperature condition is remedied.

See driver.temperature.

See lamp.temperature.

See system.temperature.

WS-

Warning - Stalled with Recovery

The axis detected a stall, but has recovered or is recovering.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

WM-

Warning - Displaced When Stationary

While not in motion, the axis has been forced out of its position.

On EtherCAT devices, the device will disable the driver and set the Driver Disabled (

FO) flag.On brake products, the device will disable the driver and set the Driver Disabled (

FO) flag.This warning persists until the axis is moved or until the user acknowledges and clears it with the warnings clear command.

WP-

Warning - Invalid Calibration Type

There is calibration data saved which this axis configuration does not support.

This warning persists until the axis configuration is changed to support the data or until the data is deleted.

WR-

Warning - No Reference Position

The axis does not have a reference position.

This warning persists until the axis position is updated by homing or any command/action that sets position.

Calibration remains disabled until the axis has been homed.

WH-

Warning - Device Not Homed

The axis has a position reference, but has not been homed. As a result, calibration has been disabled. Home the axis to re-enable calibration.

This warning persists until the axis has been homed.

NC-

Note - Manual Control

The axis is busy due to manual control via the knob.

This warning persists until a movement command is issued.

NI-

Note - Movement Interrupted

The device prematurely ended a previous motion command or displacement recovery in order to execute a newly-received movement operation (either a command or manual control). This indicates that a movement command or displacement recovery did not complete. This flag will not occur if the movement that was prematurely ended was initiated using the manual knob.

This warning persists until a movement command is issued when the axis is either idle or executing a manual control movement, or until a lockstep group is enabled on the axis.

ND-

Note - Stream/PVT Sequence Discontinuity Stream Discontinuity Stream/PVT Sequence Discontinuity

The axis has slowed down or stopped while following a stream or PVT motion path because it has run out of queued motions. In the case of a PVT sequence, this implies that time has become desynchronized, and it is no longer guaranteed that adding up the time values for each of the individual segments will equal the actual runtime of the sequence.

This warning persists until the stream has enough motions queued that it no longer needs to decelerate for that reason, or until the stream or PVT sequence is disabled.

NR-

Note - Value Rounded

One or more values in a command exceeded their specified levels of precision and were rounded.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

NT-

Note - Value Truncated

The value could not fit into a single packet and was truncated. See Line Continuation for more details.

This warning persists until acknowledged and cleared by the user with the warnings clear command.

Introduced in 7.12

Info

Info messages contain extra information from the device. One or more info messages can follow a reply to select commands.

An example of a typical info message and its fields is:

╭────────────────────────────────────────────────────── #

│╭───────────────────────────────────────────────────── n

││ ╭────────────────────────────────────────────────── a

││ │ ╭──────────────────────────────────────────────── [i]

││ │ │ ╭──────────────────────── x...

││ │ │ │ ╭─ [\][:CC]

││ │ │ ╭────────────────────┴─────────────────────╮├─ ff

#01 0 01 Visit www.zaber.com for instruction manuals.↵#-

Message Type

Size: 1 byte

The message type for an info message is always

#. n-

Device Address

Size: 2 bytes

The device address contains the address of the device sending the info, and is always formatted as two digits.

a-

Axis Number

Size: 1 byte

The axis number limits the scope of the info message, and has a value in the range of 0 to 9. An axis number between 1 and 9 indicates the info message applies specifically to that axis. An axis number of 0 indicates that the info message applies to the whole device and all axes on it.

i-

Message ID

Size: 2 bytes

The message ID of the command that elicited the info message. Omitted if the command had no message ID.

For more information about message IDs, see Message IDs.

x...-

Data

Size: 1+ bytes

The data for the info message contains command specific content.

\-

Line Continuation

Size: 1 byte

Indicates that the message cannot fit within the comm.packet.size.max comm.packet.size.max 80 80 (comm.packet.size.max) character limit of an ASCII packet and is incomplete. The remainder of the message will be sent in subsequent Info packet(s). See Line Continuation for more details.

Introduced in 7.12

:CC-

Message Checksum

Size: 3 bytes

The comm.checksum setting determines whether an info message includes a checksum.

For more information about checksums, see Checksums.

ff-

Message Footer

Size: 2 bytes

The message footer always contains a CR-LF combination (

\r\n) for an info message.

Alerts

The device sends an alert message when an axis’s status changes to IDLE. For example, on motion axes, BUSY indicates that the axis is moving, so the device will send an alert when motion completes.

Alerts are controlled by the comm.alert setting, which must be 1 for the device to send status alerts. If it is enabled, an alert can be sent at any time without being preceded by a command from the user.

This message type is used for informational purposes or time-sensitive operations.

An example of a typical alert message and its fields is:

╭────────────── !

│╭───────────── n

││ ╭────────── a

││ │ ╭─────── s

││ │ │ ╭─── w

││ │ │ │ ╭─ [x...][:CC]

││ │ ╭┴─╮ │ ├─ ff

!01 1 IDLE --↵!-

Message Type

Size: 1 byte

The message type for an alert message is always

!. n-

Device Address

Size: 2 bytes

The address indicates the address of the device sending the message, and is always formatted as two digits.

a-

Axis Number

Size: 1 byte

The axis number limits the scope of the alert, and has a value in the range of 1 to 9. The axis number indicates that the alert applies specifically to that axis.

s-

Device Status

Size: 4 bytes

On devices that control motion axes, the device status is

BUSYwhen the axis is moving andIDLEotherwise. All motion commands, including stop, put the axis into theBUSYstate while they are being executed. During streamed motion, stream wait commands are considered to be busy, not idle.On devices that control lamps, the device status is always

IDLE. Therefore, alerts will never be sent. w-

Warning Flag

Size: 2 bytes

The warning flag is the highest priority warning currently active for the device or axis, or

--when there are no warnings. For the list of warning flags, see Warning Flags. x...-

Data

Size: 0+ bytes

The contents and format of the data vary depending on the purpose of the alert. The data is omitted for alerts that do not need it.

:CC-

Message Checksum

Size: 3 bytes

The checksum is included if the comm.checksum setting is configured to 1. For more information about checksums, see Checksums.

ff-

Message Footer

Size: 2 bytes

The message footer is always composed of a CR-LF combination (

\r\n).

Multi-Axis Alerts

On a multi-axis device with completion alerts enabled, an alert is generated each time an axis stops. In the example below, axis 2 is closer to its maximum position than axis 1 is:

/move max↵

@01 0 OK BUSY -- 0

!01 2 IDLE --

!01 1 IDLE --The first alert is generated when axis 2 stops, and as that axis is idle, the axis-scope reply has IDLE in its ssss field, even though the device as a whole is still busy due to axis 1 moving. The second alert is generated when axis 1 stops.

Command Reference

The following section details available ASCII commands.

Commands are associated with either the device or its axes, which is referred to as the command’s scope. For device-scope commands, specifying an axis number other than 0 results in a DEVICEONLY error:

/1 tools parking park↵

@01 0 OK IDLE -- 0

/1 0 tools parking park↵

@01 0 OK IDLE -- 0

/1 1 tools parking park↵

@01 1 RJ IDLE -- DEVICEONLY For axis-scope commands, specifying an axis number of 0 (or omitting the axis number) directs the command to all axes on the device. If one of the axes is unable to accept the command, a BADDATA response is returned and none of the axes execute the command. For example, moving to a position that is valid for one axis, but not another, results in an error:

/1 get limit.max↵

@01 0 OK IDLE -- 3038763 6062362

/1 move abs 4750000↵

@01 0 RJ IDLE -- BADDATAactivate

Activates the peripheral

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

This command will activate the peripheral. This will set the No Reference Position (WR) warning flag, and update pos according to the value of limit.start.pos. It should be used in cases in which the controller does not automatically activate the peripheral. See the peripheral settings section for more detailed information about configuring and activating peripherals.

If the peripheral is already activated (i.e., the Peripheral Inactive (FZ) warning flag is not present), this command will be accepted but will have no side effects.

On an autodetect peripheral, this command will be accepted if a supported autodetect peripheral is plugged in. If the axis is not already configured for the plugged in peripheral (i.e., if peripheral.id does not match peripheral.id.pending), it will update peripheral.id to the value stored on the peripheral.

On a peripheral without the autodetect feature, this command will be rejected if the firmware can detect that the configured peripheral is not present.

For some peripheral and controller combinations, the controller will not be able to tell that the peripheral is unplugged until it activates the peripheral and tries to drive current. On these products, the controller will accept the activate command when the peripheral is unplugged, but will deactivate and set the Peripheral Inactive (FZ) warning flag shortly after.

Introduced in 7.11

axis restore

Restores axis-scope data to factory values

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Restores axis-scope data to the default values for the currently configured peripheral.

- Restore all axis-scope settings to their default values.

- On products that support lockstep groups, disable any lockstep group the axis is part of.

- On products that support tools parking, unpark the axis.

- On direct-drive (linear motor or voice coil) products, restore servo tuning to its default parameter set and clear parameter sets.

- On calibrated peripherals without the autodetect feature, delete any calibration data saved for the axis.

- Device-scope or volatile settings.

- Data stored via the storage command.

- Triggers will retain their previous configuration and remain enabled. If configured to do so, they may fire as a side effect of restoring axis-scope data. See the trigger commands section for more information about triggers.

- Any stored stream buffers will persist.

Introduced in 7.11

Example: Restoring an axis to its default factory configuration

The limit.max setting has been set to 1,000, a non-default value for axis 3. Issue axis restore to restore all settings on axis 3 to their default values:

/01 3 get limit.max↵

@01 3 OK IDLE -- 1000

/01 3 axis restore↵

@01 3 OK IDLE -- 0

/01 3 get limit.max↵

@01 3 OK IDLE -- 5000000The limit.max setting has been reset to its default value of 5,000,000.

driver

These commands allow enabling and disabling the driver (which controls current to the motor or load). These commands allow enabling and disabling the axis driver (which controls current to the motor). These commands allow enabling and disabling the process driver (which controls current to the load).

See the driver settings section for settings related to the driver.

driver disable

Disables the driver Disables the axis driver Disables the process driver

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Disables the driver, which prevents current from being sent to the motor or load. Disables the axis driver, which prevents current from being sent to the motor. Disables the process driver, which prevents current from being sent to the load. On firmware versions 7.10 and below, raises the Driver Temperature/Current Error Driver Temperature/Current Error Driver Disabled (FD) warning flag. On firmware versions 7.11 and above, raises the Driver Disabled (FO) warning flag. If the driver is already disabled when this command is sent, the command is accepted and the driver remains disabled.

On brake products, this command will close the brake, wait to give it time to fully close, then disable the driver before sending a reply. The motor may move slightly as the brake engages and the current is turned off.

driver enable

Enables the driver Enables the axis driver Enables the process driver

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Attempts to enable the driver. Attempts to enable the axis driver. Attempts to enable the process driver. If successful, the Hardware Emergency Stop Driver Disabled (FH), Overvoltage or Undervoltage Driver Disabled (FV), Driver Disabled (FO), Current Inrush Error (FC), Motor Temperature Error (FM), and Driver Temperature/Current Error Driver Temperature/Current Error Driver Disabled (FD) warning flags will be cleared. However, if the device detects that a driver-disabling condition is still physically present, the driver will not be enabled, and the command will be rejected with the reason DRIVERDISABLED. If the driver is already enabled when this command is sent, the command will be accepted and the driver will remain enabled.

comm

These commands assist with configuring communication interfaces.

See the comm settings section for settings related to communication interfaces.

comm en ipv4 dhcp

Enables the Ethernet DHCP client and requests network configuration details

- Parameters

- None

- Scope

- Device

- Access Level

- Normal

The Ethernet communication interface supports automatic configuration of network details via DHCP. This command enables the DHCP client and requests network configuration details. When the DHCP client is enabled, requests for updated network details are made periodically in the background.

After enabling the DHCP client, it may take the device several seconds to obtain network settings from the DHCP server. During this time, the device will retain its previous network settings. If a response is not received from the DHCP server within 6 seconds, the device will automatically assign itself a random IP address in the link-local range (169.254.0.0 to 169.254.255.255). After a reset, the device will not be able to communicate over Ethernet until this process is complete.

- comm.en.ipv4.address returns the IP address of the device.

- comm.en.ipv4.netmask returns the subnet mask.

- comm.en.ipv4.gateway returns the IP address of the default gateway.

DHCP is enabled by default on devices with Ethernet. As an alternative to using DHCP, use the comm en ipv4 static command to disable the DHCP client and specify network details explicitly.

Introduced in 7.23

Example: Enabling the Ethernet DHCP client

Enable the DHCP client and trigger an immediate DHCP request:

/comm en ipv4 dhcp↵

@01 0 OK IDLE -- 0The DHCP server now has 6 seconds to respond with network details before a fallback IP address will be assigned.

comm en ipv4 static <address> <netmask> <gateway>

Configures static Ethernet IPv4 network details

- Parameters

-

- <address>

-

The IPv4 address to use for this device

Must be in the range 1.0.0.0 to 223.255.255.255, or 0.0.0.0 to disable IPv4 networking

- <netmask>

-

The IPv4 subnet mask

Must be in the range 255.0.0.0 to 255.255.255.254 when specified in dot-decimal notation, or in the range 8 to 31 when specified as the bit-length of the network prefix

- <gateway>

-

The IPv4 address of the default gateway

Must be in the range 1.0.0.0 to 223.255.255.255, or 0.0.0.0 if not using a default gateway

- Scope

- Device

- Access Level

- Normal

Configures IPv4 network details for the Ethernet communication interface. After executing this command, the device may be reached at the IP address specified by the address parameter. Sending this command closes all existing Ethernet connections to the device, including the current connection (if this command is executed over the Ethernet communication interface). In this case, the connection needs to be reestablished in order to continue communicating with the device.

The Ethernet communication interface may be used to communicate with hosts outside the local subnet by using another host on the subnet as a gateway to other subnets and networks. This host is referred to as the default gateway, and is specified using the gateway parameter. Using a default gateway is optional and not required for devices which only communicate with other hosts on the same local subnet. In the case that a default gateway is not needed, the gateway parameter must be specified as 0.0.0.0. The netmask parameter is used to specify which IP addresses can be reached via the local subnet and which need to be forwarded to another subnet via the default gateway. To obtain the network address prefix of the current subnet, a bitwise AND is performed between the value of the netmask parameter and the value of the address parameter. Traffic to other IP addresses is checked against this prefix; if the leading bits of the target IP address match this prefix, then the message is directed to the local network. Otherwise, the message is directed to the default gateway.

As an alternative to configuring network details manually, the comm en ipv4 dhcp command can be used to configure network details automatically using DHCP.

Introduced in 7.23

Example: Manually configuring static network details

/comm en ipv4 static 192.168.0.123 255.255.255.0 192.168.0.1↵

@01 0 OK IDLE -- 0The device will use the IP address 192.168.0.123, the subnet mask 255.255.255.0, and the default gateway address 192.168.0.1.

force

These commands provide the basic methods of applying force with an axis.

force abs <force>

Applies a constant force

- Parameters

-

- Scope

- Axis

- Access Level

- Normal

Causes the axis to apply a constant force specified by the <force> parameter. A positive value applies the force in the direction of positive travel, while a negative value applies the force in the direction of negative travel. An axis applying a constant force is considered IDLE.

This command only applies to voice coil products.

Introduced in 7.25

Example: Applying a constant force

Apply a 200 µN force in the positive direction:

/force abs 200↵

@01 0 OK IDLE -- 0force off

Stops applying any force

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Removes all current to the motor, pre-empting any force or move commands. If the axis is stationary and in position control mode, the position will no longer be actively maintained.

This command only applies to voice coil products.

Introduced in 7.25

Example: Stopping all force output

/force off

@01 0 OK IDLE -- 0get <setting><scoped-setting>...

Returns the current value of a device or axis setting Returns the current value of one or more device or axis settings

- Parameters

-

- <setting>

-

The name of a setting

- <scoped-setting>

-

The name of one or more settings

Setting names can be prefixed by one or more axis numbers to change their scope

At most get.settings.max settings are permitted

- Scope

- Device and Axis

- Access Level

- Normal

Returns the current value of the named setting or settings.

See the Setting Reference for a detailed list of settings and what they do.

In firmware versions 7.35 and above multiple settings can be named. The output of this command is the value of each requested setting, separated by semicolons. All settings requested in the command will be read simultaneously, ensuring that data points are not mismatched.

If an invalid setting is requested, the response will contain an NA for that setting for each applicable axis. Not all settings exist on every Zaber product: an attempt to read a setting which is valid on one Zaber product may result in NA on a product with different features.

NA: - If any of the settings are valid device-scope settings requested in an axis-scope context, the command will be rejected with the reason

DEVICEONLY. - Otherwise, the command will be rejected with the reason

BADCOMMAND.

At most get.settings.max settings are permitted in a single get command. A command with more settings will be rejected with the reason BADDATA.

Example: Reading the value of a setting

The following command returns the device.id setting, which in this example is 50106 (X-LSQ150B):

/get device.id↵

@01 0 OK IDLE -- 50106If the specified setting is axis-scope and the product has multiple axes, the setting’s value on each axis will be returned unless a specific axis is specified. For example, the following command reads the position of all axes on a 3-axis controller:

/get pos↵

@01 0 OK IDLE -- 12345 NA 0- Axis 1 is at position 12,345.

- Axis 2 does not support the

possetting, soNAis returned. - Axis 3 is at position 0.

Example: Reading the values of multiple settings at once

In firmware versions 7.35 and above, multiple settings can be read simultaneously. For example, the following command returns the system.uptime setting along with the first two user.data settings and pos on a 2-axis device:

/1 0 get system.uptime user.data.0 user.data.1 pos↵

@01 0 OK IDLE -- 27817122.4 ; 1211 ; 3321 ; 63351 66473- The device has been powered on for 27,817.1224 seconds.

- user.data.0 and user.data.1 are 1,211 and 3,321, respectively.

- Axis 1 is at position 63,351 and axis 2 is at position 66,473.

Note how each setting listed in the command corresponds to a semicolon delimited section in the response.

Since all the settings requested in the get command are read simultaneously, system.uptime can be included to collect timestamped data points.

Example: Attempting to read nonexistent settings

Not all settings are supported on every Zaber product. Attempting to read settings that are unsupported or nonexistent results in a BADCOMMAND rejection reply:

/get nonexistent.setting↵

@01 0 RJ IDLE -- BADCOMMAND

/get this.command.is all.imaginary.setting.names which.do.not.exist↵

@01 0 RJ IDLE -- BADCOMMAND However, if the setting is supported on at least one axis, the command will be accepted and NA will be returned for the axes it is not supported on. Similarly, when reading multiple settings, if at least one of the settings is valid it will be accepted and NA will be returned for the invalid settings :

/get pos↵

@01 0 OK IDLE -- 12345 NA 0

/get fake.setting.name system.serial this.is.invalid↵

@01 0 OK IDLE -- NA ; 4294967295 ; NAAdvanced: Custom scopes for settings

When reading the values of multiple settings it may be desireable to change the requested scope of one or more settings in order to reduce the amount of data collected and transferred. To achieve this, each <scoped-setting> may start with an optional <scope-group>:

A <scope-group> is either the device-scope number (0) or one or more space-separated axis numbers (≥1). If it is omitted, it defaults to the last defined scope: either a <scope-group> or the scope of the command.

For example, the following command has three <scoped-setting>s (underlined):

/1 0 get 1 2 pos vel 0 accel↵

@01 0 OK BUSY -- 5500 4410 ; 150 200 ; 205 130 5501 2 posreturns the value ofposon axes 1 and 2: 5500 and 4410, respectively.velreturns the value ofvelon axes 1 and 2, which was the last defined scope: 150 and 200, respectively.0 accelreturns the value ofaccelon all axes (3 axes in this example): 205, 130, and 550.

Requesting an axis-scope setting with a device scope (0) will return the setting’s value on each axis, in axis number order. If a <scope-group> contains multiple axis numbers, the returned setting values will be in the same order as the specified axes.

- The group must not contain duplicated numbers. For example, the following command is invalid:

/1 0 get 1 2 1 pos↵ @01 0 RJ IDLE -- BADAXIS - The group must not include any axis numbers that are outside of the command’s scope.

- In an axis-scope command, the only valid <scope-group> is the one equivalent to the command’s scope. Therefore, specifying any <scope-group> in an axis-scope command is either invalid or superfluous. For example, the following commands are invalid:

/1 2 get 3 pos↵ @01 2 RJ IDLE -- BADAXIS /1 2 get 0 pos↵ @01 2 RJ IDLE -- DEVICEONLY - There are no restrictions on <scope-group>s in a device-scope command.

- In an axis-scope command, the only valid <scope-group> is the one equivalent to the command’s scope. Therefore, specifying any <scope-group> in an axis-scope command is either invalid or superfluous. For example, the following commands are invalid:

- The group contains one but not both of:

- The device scope number (0).

- One or more axis numbers (≥1).

/1 0 get 0 1 pos↵ @01 0 RJ IDLE -- BADAXIS

BADAXIS. The one exception is when a device-scope <scope-group> (0) is specified in an axis-scope command. In that case the rejection reason will be DEVICEONLY instead. BADDATA: /1 get pos 1↵

@01 0 RJ IDLE -- BADDATAhome

Moves the axis towards the home sensor to set the reference position

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Moves the axis towards the home position at the lesser of limit.approach.maxspeed and maxspeed until the home sensor is triggered. Once the home position is reached, the current position is reset to limit.home.preset, establishing the reference position. Additionally, limit.home.triggered is set to 1, and the No Reference Position (WR) warning flag is cleared.

This command is similar to issuing /tools gotolimit home neg 2 0. On some products, the axis may reverse direction when searching for the home sensor during homing. However, tools gotolimit will only search in the specified direction.

Example: Homing

/home↵

@01 0 OK BUSY WR 0home measure phase

Measures the motor phase at the index mark

- Parameters

- None

- Scope

- Axis

- Access Level

- Normal

Performs a modified version of the homing routine that measures the motor phase at the index mark; see home for a more detailed description of the homing routine and side effects. In order to measure the phase at the index mark some steps of homing are done with open-loop control. After homing, limit.ref.phase.measured will be set to the measured phase.

Example: Measuring and setting motor phase at the index mark

/home measure phase↵

@01 0 OK BUSY WR 0

!01 0 OK IDLE -- 0

/get limit.ref.phase.measured↵

@01 0 OK IDLE -- 1190

/set limit.ref.phase 1190↵

@01 0 OK IDLE -- 0io

These commands provide access to the digital or analog input or output (IO) channels on the device.

There are four types of IO channels:

- ao

- Analog output

- ai

- Analog input

- do

- Digital output

- di

- Digital input

All IO channels of a particular type are collectively called a port and each channel is identified by its position within the port. For instance, do 1 is the first digital output. Note that channels only have one type and cannot change types, e.g., a digital output cannot function as a digital input.

Not all IO types are available on every device. Use the io info command to see the IO channels available on a particular device.

io cancel schedule <type> <channel>|(port [<action>...])

Cancels a scheduled IO action

- Parameters

-

- <type>

-

The type of IO channel

Must be one of

ao(analog output), ordo(digital output).Must be

do(digital output) - <channel>

-

The channel number

Must be in the range 1 to the value returned by io info for the channel type of <type>

- <action>

-

When the port parameter is specified, a space-separated list of actions, one for each channel in the port (optional).

Each action must be one of

0(ignore) or1(cancel scheduled action).

- Scope

- Device

- Access Level

- Normal

Cancels IO scheduled on one or more IO channels using the io set do schedule command or the io set ao schedule command.

If port is provided without <action>, all scheduled IO on all channels in the port will be canceled.

Introduced in 7.37

Example: Canceling a scheduled action on a channel

Cancel any scheduled action on digital output channel 2:

/io cancel schedule do 2↵

@01 0 OK IDLE -- 0Example: Canceling scheduled actions on multiple channels

Cancel any scheduled actions on digital output channels 1 and 4 but not 2 and 3:

/io cancel schedule do port 1 0 0 1↵

@01 0 OK IDLE -- 0Example: Canceling scheduled actions on a port

Cancel any scheduled actions on all digital output channels:

/io cancel schedule do port↵

@01 0 OK IDLE -- 0io get ai <channel>|port

Returns the voltage of an analog input channel or port

- Parameters

-

- <channel>

-

The analog input channel number

Must be in the range 1 to the value returned by io info ai

- port

-

Return the voltages for all analog input channels

- Scope

- Device

- Access Level

- Normal

Returns the voltage measured on the specified analog input channel in volts with a sufficient number of decimal places to capture the available resolution. If the port parameter is provided, this command returns a space-separated list of voltages, one for each channel in the port.

Introduced in 7.11

Example: Reading an analog input

/io get ai 1↵

@01 0 OK IDLE -- 7.5Analog input 1 has 7.5 V applied to it.

io get ao <channel>|port

Returns the voltage of an analog output channel or port

- Parameters

-

- <channel>

-

The analog output channel number

Must be in the range 1 to the value returned by io info ao

- port

-

Return the voltages for all analog output channels

- Scope

- Device

- Access Level

- Normal

Returns the voltage the device is currently driving the specified analog output channel at, in volts with a sufficient number of decimal places to capture the available resolution. If the port parameter is provided, this command returns a space-separated list of voltages, one for each channel in the port.

Introduced in 7.11

Example: Reading an analog output

/io get ao 1↵

@01 0 OK IDLE -- 7.5The device is driving analog output 1 to 7.5 V.

io get di <channel>|port

Returns the state of a digital input channel or port

- Parameters

-

- <channel>

-

The digital input channel number

Must be in the range 1 to the value returned by io info di

- port

-

Return the states for all digital input channels

- Scope

- Device

- Access Level

- Normal

This command returns the state of the specified digital input channel. If the port parameter is provided, this command returns a space-separated list of values, one for each channel in the port. The command returns 0 for off or 1 for on.

In firmware versions 7.22 and above, the state of the digital input port can also be read using the io.di.port setting.

0 (off) and 1 (on) states are product dependent. See the product’s User Manual for a description of its behaviour. Introduced in 7.07

Example: Reading a digital input

/io get di 2↵

@01 0 OK IDLE -- 1Digital input 2 is on.

Example: Reading all digital inputs

/io info di↵

@01 0 OK IDLE -- 2

/io get di port↵

@01 0 OK IDLE -- 0 1The device has two digital inputs: digital input 1 is off, and digital input 2 is on.

io get do <channel>|port

Returns the state of a digital output channel or port

- Parameters

-

- <channel>

-

The digital output channel number

Must be in the range 1 to the value returned by io info do

- port

-

Return the states for all digital output channels

- Scope

- Device

- Access Level

- Normal

This command returns the state the device is currently driving the specified digital output channel at. If the port parameter is provided, this command returns a space-separated list of values, one for each channel in the port. The command returns 0 for off or 1 for on.

In firmware versions 7.22 and above, the state of the digital output port can also be read using the io.do.port setting.

0 (off) and 1 (on) states are product dependent. See the product’s User Manual for a description of its behaviour. Introduced in 7.07

Example: Reading a digital output

/io get do 2↵

@01 0 OK IDLE -- 1The device has turned on output 2.

Example: Reading all digital outputs

/io info do↵

@01 0 OK IDLE -- 2

/io get do port↵

@01 0 OK IDLE -- 0 1The device has two digital outputs: digital output 1 is off, and digital output 2 is on.