X-NA-SV2 Series

High vacuum micro linear actuators with built-in controllers

About This Series

Zaber's X-NA-SV2 Series devices are high-vacuum compatible, computer-controlled, motorized miniature linear actuators with high thrust and speed capabilities, and a compact size. They are stand-alone units requiring only a standard 24 V or 48 V power supply.

These actuators connect to the RS-232 port or USB port of any computer, and they can be daisy-chained with any other Zaber products. The daisy-chain also shares power, making it possible for multiple X-Series products to share a single power supply.

At only 20 mm wide, these miniature actuators are excellent for applications where a small profile is required. The X-NA-SV2 is designed with vacuum compatible materials to minimize outgassing and allow for faster pump down times. Like all of Zaber's products, the X-NA-SV2 Series is designed to be 'plug and play' and very easy to set up and operate.

For more information about the basics of a vacuum system and considerations to keep in mind when gathering requirements for your application, read our technical article, "Motion Device Design Considerations for Vacuum Applications".

See our Vacuum Compatible TSB-V Linear Slides for more information on compatible slides.

- Integrated stepper motor controller and motor driver allows for easy-to-use control.

- Vacuum compatible greases and epoxies are used.

- Only 4 feedthrough wires required to control all units in the daisy-chain via serial port (with an X-PIB adaptor).

- Daisy-chain additional units to reduce wiring clutter. Power and data can be shared in the chain.

- High vacuum compatible stepper motors rated to 10-6 torr.

- Flexible M3 mounting interface. Heat transfer tab can be moved from one side to another to free up mounting holes on desired surface.

- Precision lead screw, stepper motor and advanced algorithm enable 50 nm resolution.

- Standard mounting interface replaces most manual micrometer heads.

- M3, flat tip, or ball tip interface option included with every actuator.

Easy Set-Up

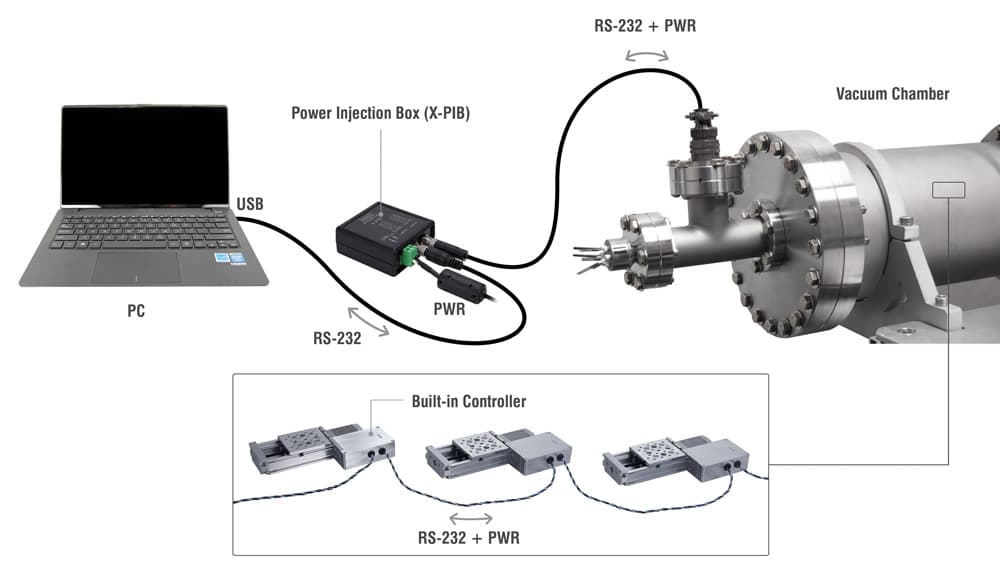

Control and Power Multiple Devices With Only Four Feedthrough Wires

- Connect data and power cables between computer and vacuum chamber.

- Devices with built-in controllers receive power and data in the vacuum chamber via 4 feedthrough wires*.

- Send instructions or automate your set-up using the Zaber Launcher.

* For X-Series devices, power is injected via the X-PIB. T-Series devices require 5 feedthrough wires and the T-DSUB9-P for power injection.

For more details on setting up vacuum devices, read our technical article, "Motion Device Design Considerations for Vacuum Applications".

For additional information about setting up our devices, please visit our Support page, which includes our Getting Started Guide, Troubleshooting Guides, product user manuals, and other resources.