Representative Image

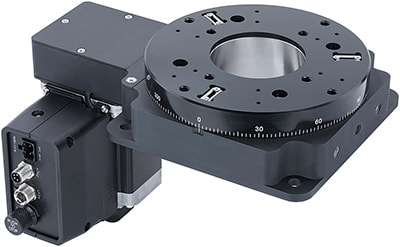

RSB Family

High Speed Belt Drive Rotary Stage

- Belt driven for high speed, efficiency and lifetime

- 60 and 120 mm stage top diameter

- Power-off brake option for load protection during power interrupts

- Built-in controller or motor models only

- Motor encoder option for slip/stall detection and automatic recovery

- Multiple motor mounting configurations

- Contact us for information and custom options for cleanroom use

| Best Accuracy | Best Backlash | Best Repeatability | Highest Speed | Highest Torque | Load |

|---|---|---|---|---|---|

0.2° (3.490000 mrad) | < 0.1° (< 1.745 mrad) | < 0.001° (< 0.017 mrad) | 7200°/s (1200 rpm) | 750 N⋅cm (1062.1 oz⋅in) | 500 N (112.1 lb) |

| Series Name | Optional Brake | Built-In Controller | Built-In Encoder | Built-In Motor | Price Range ( USD ) * | Current Lead Times | Add To Compare |

|---|---|---|---|---|---|---|---|

| X-RSB-E | Motor/rotary | Stepper | $2,721 – $4,685 | 1-5 Days | |||

| X-RSB | Stepper | $2,445 – $3,702 | 1-5 Days | ||||

| RSB-E | Motor/rotary | Stepper | $1,874 – $3,765 | 1-5 Days | |||

| RSB | Stepper | $1,631 – $2,753 | 1-5 Days |

* These are our direct prices in USD to customers in North America. If you are in Canada, click the Canadian flag icon at the top right of the page to see CAD prices. If you are in a country outside North America where we have an exclusive distributor, please check with the distributor for pricing. Distributor prices might be slightly higher to factor in shipping and import fees. Click here for a list of Zaber's Distributors.

RSB Customization Examples

Whether you need modifications to standard products or have unique stage or system needs, our Product Customization team is dedicated to building tailored solutions.

Response Time Promise: 1 Business Day

Custom Gimbal with Through-Bore Slip Ring

The Challenge: A customer needed continuous two-axis rotation for a new instrument but also required clear, unobstructed access through the center to mount a stationary object. Standard rotary stages include an aperture, but running cables through a continuously rotating stage can cause cables to tangle. Zaber's standard gimbals include optional slip rings to provide unrestricted rotation with cables but this component occupies the rotary stage aperture.

The Solution: Our Custom Engineering team designed a custom miniature gimbal that integrates a through-bore slip ring.

The Outcome: The slip ring handles all electrical connections, allowing for infinite, tangle-free rotation, while the hollow center remains open for the customer's stationary hardware.

Zaber's Technical Advantage: The gimbal was built using Zaber's standard X-RSB-E and X-RSW-E rotary stages. These devices have integrated controllers and daisy-chain with a single cable for power and data, minimizing cable clutter, making this complex system remarkably simple to integrate.