XY Stage Selection for Microscopy

By Mike Fussell, Marketing Team

Published on Feb. 25, 2022

Selecting the XY stage for your microscope is a crucial decision. This article introduces the key XY stage specifications and describes how to use them to select the best stage for your application.

X & Y-Axis Travel

Stage travel is typically determined by the size of the sample being imaged. For a single slide, petri dish, or microplate, 120 mm x 100 mm travel will be sufficient. For maximum walk-away time, the 305 mm x 305 mm stage can hold up to six standard microplates.

| Target | Recommended Stage |

|---|---|

| 1 x petri dish | ASR 120 mm x 100 mm ADR 130 mm x 100 mm |

| 1 x slide | ASR 120 mm x 100 mm ADR 130 mm x 100 mm |

| 4 x slide | ASR 120 mm x 100 mm ADR 130 mm x 100 mm ADR 250 mm x 100 mm |

| 8 x slide | ADR 250 mm x 100 mm |

| 1 x microplate | ASR 120 mm x 100 mm ADR 130 mm x 100 mm |

| 2 x microplate | ASR 205 mm x 205 mm ADR 250 mm x 100 mm |

| 3 - 6 x microplate | ASR 305 mm x 305 mm |

Table 1: Recommended XY stages for different targets

Figure 1: Stage travel for X-ASR and X-ADR series compared to standard microplate

Accuracy and Repeatability

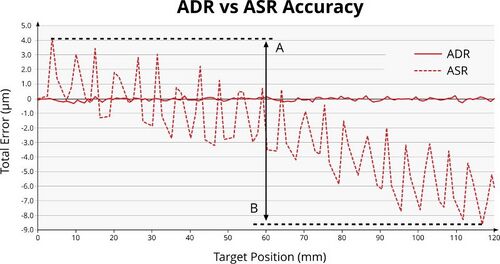

Accuracy is the largest possible difference between the reported position of a stage position and its true position. As the travel of X-ASR stepper motor stages increases, the maximum error possible will also increase.The accuracy of X-ADR linear motor driven stages remains the same, regardless of their travel. High accuracy is beneficial for image stitching applications as it enables less overlap between images, which in-turn speeds up the scanning time. With low-distortion optics, if the accuracy is better than the size of a single pixel, no image stitching algorithm is required.

Figure 2: Accuracy is measured as the largest possible difference between expected and actual target positions. This is shown as the distance between points A and B. X-ASR series of stages show greater positioning error than linear motor driven X-ADR stages.

Repeatability is a measure of how accurately a stage can return to the same position over multiple movement cycles from the same direction. The linear motors of ADR stages deliver superior repeatability giving them more consistent performance on repeated tasks.

X-ADR series stages use direct encoders to measure their position, enabling them to fine tune their positioning to compensate for external forces. The 1 nm resolution of X-ADR encoders enables them to detect vibrations in the stage which could blur images captured at high magnifications. The stage can output an IO trigger signal when the vibrations have settled below a target threshold, improving throughput compared to waiting for an arbitrary settling time.

X-ASR series stages use motor encoders to detect slipping or stalling of stepper motors due to external forces or exceeding thrust limits. Detecting slips or stalls which result in a discrepancy between intended and actual stage position enables corrective actions to be taken and prevents erroneous results due to inaccurate sample positioning.

Speed

Linear motor driven X-ADR stages are capable of moving at up to 750 mm/s while the stepper motor driven X-ASR stages' maximum speed is 85 mm/s.

For high magnification imaging where the stage must settle completely to capture sharp images, X-ADR stages support closed loop servo control for shorter settling times and faster cycle times relative to the X-ASR series. X-ADR stages can detect when they have settled below a target threshold and automatically trigger image acquisition, eliminating the need for arbitrary settling delays, further reducing cycle times and improving throughput.

| XY Stage | Drive | Minimum 96-Well Scanning Time | Minimum 384 Well Scanning Time |

|---|---|---|---|

| X-ADR | Linear Motor | < 12 seconds | < 46 seconds |

| X-ASR | Stepper Motor | < 19 seconds | < 58 seconds |

Table 2: The minimum scanning time is the time required to traverse standard microplate with a 100X objective stopping at each well to settle and capture a 25 µs exposure. Scanning times will vary on a case-by-case basis depending on camera, fluorophore, imaging parameters, illumination wavelength and objective selection. Stage service life will vary depending on the stage load, speed and acceleration. Higher loads at higher speeds will result in increased wear of stepper motor stage components.

Continuous high-throughput operation

The repeated short, high acceleration movements encountered during high speed plate scanning can result in increased mechanical wear on the lead screw and lead nut of X-ASR stages. Higher loads and greater acceleration will reduce the expected lifespan from 95 million cycles at 0.3 N to 15 million cycles at 1.3 N. X-ADR series stages are recommended for applications requiring extended operations at maximum speed and thrust as they are direct drive stages (no leadscrew or lead nut). In addition, their higher maximum speed enables faster cycle times while their direct drive design delivers a greatly extended lifetime.

Other considerations

Linear motor X-ADR stages deliver a significant “quality-of-life” advantage over X-ADR stepper motor stages. They are virtually silent, making them ideal for labs where they will be operating continuously for long periods in spaces shared with people. When unpowered, linear motor stages can be moved freely for quick coarse positioning or for applying oil to immersion objectives. Stepper motor X-ASR stages do not allow for free motion when unpowered.

Summary

| Specification | Why it matters | ASR (Stepper Motor) | ADR (Linear Motor) |

|---|---|---|---|

| Minimum Incremental Move | Small moves enable rapid, fine position adjustment | < 0.47 µm | 50 nm |

| Maximum Speed | Greater maximum speed enables a faster scanning for higher throughput | 65 mm/s - 85 mm/s | 750 mm/s |

| Accuracy (unidirectional) | The maximum error possible when moving between any two positions, when both positions are approached from the same direction. | 12 µm - 80 µm Accuracy decreases as length of travel increases due to accumulation in lead screw error. | 5 µm |

| Repeatability | Ability to return to a target position multiple times from the same direction. High repeatability ensures consistent positioning to maximize consistency of results. | < 2 µm | < 0.5 µm |

| Service Life | Long service lives of many million cycles ensure highly reliable operation for continuous, high-throughput applications. | Accuracy is reduced as drive components wear over time. Wear is accelerated by extended operation at maximum speed. | Not impacted by extended operation at maximum speed |

| Operating Noise | Silent operation is beneficial for people sharing space with operating stages for long periods of time. | Velocity dependent noise | Virtually silent operation at any speed |

Table 3: Summarized differences between lead screw and linear motor drive for Nucleus MVR XY stage.