X-RSB-E Series

High speed motorized rotary stages with built in controllers, motor encoders, and optional brakes

About This Series

Zaber's X-RSB-E Series rotation stages feature a compact footprint, low profile, and a load capability of up to 50 kg. With a maximum speed of 1,200 rpm, these rotation stages are ideal for the rapid positioning of light loads to within a fraction of a degree.

They are stand-alone units requiring either a standard 24 V or 48 V power supply. A built-in motor encoder allows for closed-loop operation and slip/stall recovery features. There are two motor configurations available: up and down. Motor up configurations allow flush mounting of the device to a flat surface, and motor down configurations allow for a full 360° movement of loads that extend past the edge of the stage top. An indexed knob provides convenient manual control for versatile operation even without a computer. An optional power-off brake is available to protect the payload from unintended motion in the event of power loss.

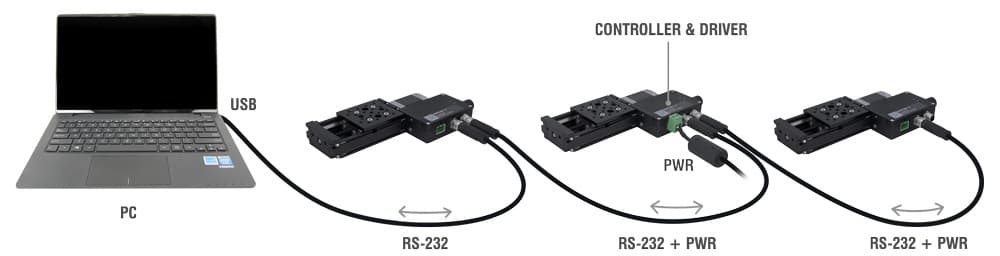

These stages connect to the RS-232 port or USB port of any computer, and they can be daisy-chained with any other Zaber products. The daisy-chain also shares power, making it possible for multiple X-Series products to share a single power supply. Convenient locking, 4-pin, M8 connectors on the unit allow for secure connection between units. Like all of Zaber's products, the X-RSB-E Series is designed to be 'plug and play' and very easy to set up and operate.

- Integrated controller and stepper motor driver provide easy-to-use motion.

- Integrated motor encoder, provides easy-to-use closed-loop motion.

- 200 step per revolution stepper motor, microstepped up to 256x to provide smooth and precise motion.

- Control all units in the daisy-chain via serial port (with a locking X-SDC cable) or USB (with an X-USBDC cable).

- Daisy-chain additional units with a locking X-DC02 cable or X-DC06 cable. Power can also be shared in the chain.

- Stage top supports multiple mounting options.

- Innovative design allows for superior speed & load capabilities; up to 1,200 rpm & 50 kg load.

- Belt drive allows high speed, low noise, and low backlash positioning.

- Straight through aperture.

- Flexible mounting options; can be mounted directly on other Zaber stages.

- An optional power-off brake is available to protect payload from unintended motion in the event of power loss.

Easy Set-Up

Zaber's devices can share both data and power through a daisy-chain, which reduces cabling and makes set-up as easy as 1, 2, 3:

- Connect the Zaber device to your computer via USB or RS-232 port.

- Connect the power supply to your Zaber device.

- Send instructions or automate your set-up using the Zaber Launcher.

For more details on daisy-chaining, read our technical article, "Daisy-chaining Data and Power to Reduce Cabling", or to determine which accessories you need for your system, try our Connection Guide Tool.

For additional information about setting up our devices, please visit our Support page, which includes our Getting Started Guide, Troubleshooting Guides, product user manuals, and other resources.