Manuals/ASCII Protocol Manual

This document is applicable to devices with Firmware 6.xx. If your device uses Firmware 7.xx, refer to the Firmware 7 ASCII Protocol Manual. See here for instructions on how to tell which version your device uses.

The ASCII protocol is a format for sending and receiving information with your Zaber devices. It can be used with A-Series and X-Series devices that have firmware 6.06 or higher. It's designed to be an easy and intuitive method for communicating in plain text. This manual will help you set up your connection, choose which software to use, and help you start operating your Zaber Device. There are also references for the list of all commands and settings and the complete message structure.

If you are interested in knowing more about other possible communication protocols, or if your device uses a firmware lower than 6.06, please see the Binary Protocol manual. See Appendix C for how to switch between these protocols.

Conventions Used Throughout this Document

- Fixed width type indicates ASCII characters communicated to and from a device.

- The ↵ symbol indicates a newline. When sending a command to a device, ↵ can be any combination of the Carriage Return (CR, '\r', ASCII code 13) and/or Line Feed (LF, '\n', ASCII code 10) characters. In responses from a device, ↵ includes both the Carriage Return and Line Feed characters.

- Most of the devices covered by this document use stepper motors, so the document refers to microsteps whenever discussing resolution. For devices that do not use stepper motors, the encoder resolution should be substituted.

Previous Versions

As new features are added to the ASCII protocol, archived versions of this manual will become available below. Please consult the correct manual for your device version.

Quick Start

Connecting

Zaber A-Series and X-Series devices support connecting to user equipment over standard serial connections using a human-readable, text-based protocol. This allows these devices to interface with a variety of equipment and software, including:

- Zaber Console

- Zaber Launcher

- Terminal Emulators

- User programs

- PLCs

- Automation and Instrumentation packages

Zaber devices can be up and running in a matter of minutes, no matter what environment is being used.

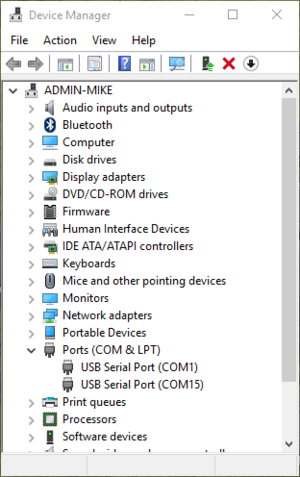

A-Series and X-Series devices typically communicate over RS232 at 9600 or 115200 baud, with 8 bits, 1 stop bit and no parity, however please refer to the RS232 Communications section of the device-specific User Manual for the correct settings. Characters are not echoed by the device, so if a terminal emulator is being used, it is advisable to turn on local echo.

For detailed instructions on how to set up and configure various communication software, please refer to the Communication Software section below.

Talking to Zaber Devices

Zaber devices listen for Commands sent to them over a serial port and then immediately respond with a Reply. Commands always begin with a / and end with a newline. Some commands take parameters, which are separated by spaces. Two example commands are:

/1 help↵ /1 move abs 10000↵

Where the move command has parameters of abs and 10000.

Replies begin with a @, have 4 or more parameters and end with a newline. For example, the most common reply is:

@01 0 OK IDLE -- 0

Which can be broken down into:

@ A Reply

01 The ID of the device sending the reply

0 The reply scope. 0 for the device or all axes, 1 onwards for an individual axis.

OK The command succeeded.

IDLE The device isn't moving, otherwise BUSY if it is moving.

-- No faults or warnings in the device

0 The return value, typically 0.

A complete description of the reply fields is available in the Replies section.

Devices can also send two other types of messages; Alerts, starting with ! and Info, starting with #. Info messages are commonly seen in response to a help command.

Making it Move

Before a device can moved, it first needs to establish a reference to the home position. This is achieved by sending the home command, as shown below:

/home↵ @01 0 OK BUSY WR 0

If the device isn't homed and a move command is attempted, the device will respond with a rejection reply and the Invalid Reference (WR) flag set:

/move rel 10000↵ @01 0 RJ IDLE WR BADDATA

Once the device has been homed, you can make the device move by sending a move command. For example, to move 10000 microsteps forward from the current position:

/move rel 10000↵ @01 0 OK BUSY -- 0

To move 10000 microsteps away from the home position, regardless of the current position:

/move abs 10000↵ @01 0 OK BUSY -- 0

Changing a Device Setting

All of the device settings are read and modified using the get and set commands. For example, to query the device maxspeed:

/get maxspeed @01 0 OK IDLE -- 153600

The maximum speed setting is currently 153600. The speed in microsteps/sec is calculated as data / 1.6384, which equates to 93750 microsteps/sec for the data value of 153600.

On a multi axis device, the same command would return a value for each of the axes. For example:

/get maxspeed @01 0 OK IDLE -- 153600 153600

To set the device to move at a target speed of 50000 microsteps/sec, the speed setting would be modified as shown below:

/set maxspeed 81920 @01 0 OK IDLE -- 0

On a multi axis device, the command above would set the speed for all axes. To only query or set a value for a specific axis, see the Talking to an Individual Axis section below.

Talking to an Individual Device

Up until now all the commands that have been sent haven't included a device address. If you have more than one device in a chain, you may have noticed that all of the devices moved at once in the Making it Move example above and that multiple responses were received. While this is a handy feature for initial setup, general use requires a way to instruct only an individual device to move.

Devices can be addressed by including their device number before the command. For example, the following command instructs only device 1 to move:

/1 move abs 10000↵ @01 0 OK BUSY -- 0

The valid device addresses are from 1 - 99 inclusive and can include a leading zero for devices 1 - 9. For example either 01 or 1 would both refer to device 1.

Talking to an Individual Axis

On multi axis devices, all the commands shown above would have affected all axes in the device. In order to get only a single axis to move an axis number has to be provided after the device number. The following command would instruct the first axis on a device to move to position 10000.

/1 1 move abs 10000↵ @01 1 OK BUSY -- 0

Note that this time the response scope is 1, indicating that the following information applies to axis 1.

Valid axis numbers are 0 - 9 inclusive, where 0 means all axis of the device, depending on the command or setting.

Built-in Help

All Zaber A-Series and X-Series devices feature built-in help, providing a quick and easy reference for all Commands and Settings that the device has. Help commands require a device number to be provided. For example to access the built-in help for device 1, send: /1 help↵.

The device will respond with a detailed description on how to access specific information about commands and replies, as shown below:

/1 help↵ @01 0 OK IDLE WR 0 #01 0 COMMAND USAGE: #01 0 '/stop' stop all devices #01 0 '/1 stop' stop device number 1 #01 0 '/1 2 stop' stop device number 1 axis number 2 #01 0 #01 0 Type '/help commands' for a list of all top-level commands. #01 0 Type '/help reply' for a quick reference on reply messages. #01 0 Visit www.zaber.com/support for complete instruction manuals.

Note that you can view a list of all the top level commands available to device 1 by using /1 help commands↵. To access help for a specific command, for example the move command, send:

/1 help move↵

@01 0 OK IDLE -- 0

#01 0 move abs {x} Move to absolute position

#01 0 move rel {x} Move by relative position

#01 0 move vel {x} Move at constant velocity

#01 0 move min Move to minimum position

#01 0 move max Move to maximum position

Quick Command Reference

The following table offers a quick command and setting reference for ASCII devices. For more detailed information, refer to the Command Reference or Device Settings below.

Quick Commands

Parameters in square brackets, e.g. [clr], indicate that the parameter is optional.

Parameters in italics, e.g. value, indicate that data, typically a number, needs to be provided.

Parameters separated by a pipe, e.g. abs|rel, indicate that one of the parameters in the set need to be provided.

| Command | Scope | Parameter(s) | Returns | Firmware Versions | Description |

|---|---|---|---|---|---|

| calibration | Device | Refer to the documentation below | 0 | 6.24+ | Configure linear encoder calibration. |

| estop | Axis | 0 | 6.06+ | Instantly stops motorized movement. | |

| force | Axis |

abs value |

0 | 6.25+ | Applies a constant or sinusoidal force to a voice coil device. |

| get | Device and Axis | setting | value | 6.06+ | Retrieves the current value of the device or axis setting. |

| help | Device | commands reply warnflags enums command ... enum |

0 | 6.06+ | Displays the help information for the system. |

| home | Axis | 0 | 6.06+ | Moves the axis to the home position. | |

| io info | Device |

[ai|ao|do|di] |

ports | 6.06+ | Returns the number of I/O channels the device has. |

| io get | Device |

ai|ao|do|di [channel] |

value | 6.06+ | Returns the current value of the specified I/O channel type. |

| io set | Device | ao channel value do channel value do port value value2... |

0 | 6.06+ | Sets the specified output channel to value. |

| joystick | Device | Refer to the documentation below | Refer to the documentation below | 6.16+ | Configures joystick axes. |

| key | Device | Refer to the documentation below | Refer to the documentation below | 6.16+ | Configures joystick keys. |

| lockstep | Device | Refer to the documentation below | Refer to the documentation below | 6.15+ | Sets up and controls synchronized motion of a group of parallel axes. |

| move | Axis |

abs|rel|vel value |

0 | 6.06+ | Moves the axis to various positions along its travel. |

| renumber | Device | value | 0 | 6.06+ | Renumbers all devices in the chain. |

| servo | Axis | Refer to the documentation below | Refer to the documentation below | 6.25+ | Configures position control servo tuning of a voice coil device. |

| set | Device and Axis | setting value | 0 | 6.06+ | Sets the device or axis setting setting to the value. |

| stop | Axis | 0 | 6.06+ | Decelerates the axis and brings it to a halt. | |

| stream | Device | Refer to the documentation below | Refer to the documentation below | 6.12+ | Performs an action related to streamed, interpolated motion. |

| system reset | Device | 0 | 6.06+ | Resets the device, as it would appear after power up. | |

| system restore | Device | 0 | 6.06+ | Restores common device settings to their default values. | |

| tools detectholder | Axis | 0 | 6.22+ | Detects the currently installed filter holder. | |

| tools echo | Device | (message) |

0 | 6.06+ | Echoes the provided message (if any) back to the user. |

| tools findrange | Axis | 0 | 6.10+ | Uses the home and away sensors to set the valid range of the axis. | |

| tools gotolimit | Axis | limit dir action update | 0 | 6.06+ | Moves the axis to a limit sensor and performs the provided actions. |

| tools parking | Device |

state|park|unpark |

0|1 |

6.06+ | Parking allows the device to be turned off and used at a later time without first having to home. |

| tools setcomm | Device | rs232baud protocol | 0 | 6.06+ | Sets RS232 baud rate and communication protocol for RS232 and USB. |

| tools storepos | Axis |

number [position|current] |

0|position |

6.06+ | Stores a number of positions for easy movement. |

| trigger | Device | Refer to the documentation below | 0 | 6.06+ | Configures actions to be performed on the device when a certain condition is met. |

| trigger dist | Device | number axis displacement number enable [count] number disable |

0 | 6.06+ | Configures a trigger to toggle a digital output line every displacement microsteps. |

| trigger time | Device | number period number enable [count] number disable |

0 | 6.06+ | Configures a periodic trigger to toggle a digital output line every period milliseconds. |

| virtual | Device | Refer to the documentation below | Refer to the documentation below | 6.18+ | Sets up and controls a pair of axes to allow movement along a virtual axis. |

| warnings | Axis | [clear] |

0 | 6.06+ | Displays the active device and axis warnings, optionally clearing them if applicable. |

Quick Device Settings

The settings listed below can be inspected and modified with the get and set commands described above.

| Setting | Scope | Writable | Firmware Versions | Description |

|---|---|---|---|---|

| accel | Axis | Yes | 6.06+ | Sets the acceleration used to modify the speed. |

| calibration.type | Axis | No | 6.24+ | The type of calibration saved for the axis. |

| cloop.counts | Axis | Yes | 6.06+ | The number of counts generated by the encoder for one full revolution. |

| cloop.displace.tolerance | Axis | Yes | 6.19+ | The minimum deviation in the position of a stationary axis that will register as a displacement. |

| cloop.duration.max | Axis | Yes | 6.17+ | The duration for attempting fine position correction. |

| cloop.mode | Axis | Yes | 6.06+ | The closed-loop (slip, stall, and displacement detection and recovery) control mode. |

| cloop.stalltimeout | Axis | Yes | 6.06+ | The amount of time to wait after a stall/displacement condition, in milliseconds. |

| cloop.steps | Axis | Yes | 6.06+ | The number of full steps required for the motor to complete one revolution. |

| comm.address | Device | Yes | 6.06+ | The device address. |

| comm.alert | Device | Yes | 6.06+ | The device will send alert messages when this setting is 1. |

| comm.checksum | Device | Yes | 6.06+ | The device includes checksums in its messages if this setting is set to 1. |

| comm.protocol | Device | Yes | 6.06+ | The communications protocol used by the device on the current interface. |

| comm.rs232.baud | Device | Yes | 6.06+ | The baud rate used by RS232 Prev and Next interfaces. |

| comm.rs232.protocol | Device | Yes | 6.09+ | The protocol used by RS232 Prev and Next interfaces. |

| comm.rs485.baud | Device | Yes | 6.09+ | The baud rate used by RS485 interface. |

| comm.rs485.enable | Device | Yes | 6.09+ | Enables the RS485 interface. |

| comm.rs485.protocol | Device | Yes | 6.09+ | The protocol used by RS485 interface. |

| comm.usb.protocol | Device | Yes | 6.09+ | The protocol used by the usb interface. |

| deviceid | Device | No | 6.06+ | The device ID for the unit. |

| driver.current.hold | Axis | Yes | 6.06+ | Current used to hold the motor in position, in 20 mA DC increments. |

| driver.current.max | Axis | No | 6.16+ | Maximum legal value of driver.current.hold and driver.current.run. |

| driver.current.run | Axis | Yes | 6.06+ | Current used to drive the motor, in 14.1 mA RMS (20 mA peak) increments. |

| driver.dir | Axis | Yes | 6.06+ | Reverse the motor driver output direction. |

| driver.temperature | Axis | No | 6.06+ | The current temperature of the axis driver, in degrees Celsius. |

| encoder.count | Axis | Yes | 6.06+ | The recorded counts of the axis encoder. |

| encoder.count.calibrated | Axis | No | 6.24+ | The calibrated counts of the axis encoder. |

| encoder.dir | Axis | Yes | 6.06+ | Inverts the counting direction for the axis encoder. |

| encoder.error | Axis | No | 6.17+ | Position error measured by encoder. |

| encoder.fault.type | Axis | Yes | 6.24+ | The type of fault signal provided by the encoder. |

| encoder.filter | Axis | Yes | 6.06+ | Enable and set up digital filtering of the encoder inputs. |

| encoder.index.count | Axis | Yes | 6.06+ | The recorded counts of the axis encoder index pulse. |

| encoder.index.mode | Axis | Yes | 6.06+ | The operating mode of the axis encoder index signal. |

| encoder.index.phase | Axis | Yes | 6.06+ | The required phase for an index pulse to be counted. |

| encoder.mode | Axis | Yes | 6.06+ | The operating mode of the axis encoder. |

| encoder.pos | Axis | No | 6.17+ | Position measured by encoder. |

| filter.holderid | Axis | Yes | 6.22+ | The ID of the installed filter holder. |

| force.average | Axis | Yes | 6.25+ | Average force applied recently by the axis. |

| joy.debug | Device | Yes | 6.16+ | Joystick debugging mode. |

| knob.dir | Axis | Yes | 6.06+ | Sets the movement direction for the knob. |

| knob.distance | Axis | Yes | 6.06+ | Sets how far the device moves with each step of the knob in displacement mode, in units of microsteps. |

| knob.enable | Axis | Yes | 6.06+ | Disable the use of the knob when set to 0. |

| knob.force | Axis | Yes | 6.25+ | The maximum force that can be reached using the knob in force mode. |

| knob.forceprofile | Axis | Yes | 6.25+ | Sets the profile to be used per increment when in force mode. |

| knob.maxspeed | Axis | Yes | 6.06+ | The maximum speed that can be reached using the knob in velocity mode. |

| knob.mode | Axis | Yes | 6.06+ | Sets the mode of the manual control knob. |

| knob.speedprofile | Axis | Yes | 6.06+ | Sets the profile to be used per increment when in velocity mode. |

| limit.approach.maxspeed | Axis | Yes | 6.06+ | Maximum speed used when approaching a limit sensor. |

| limit.cycle.dist | Axis | Yes | 6.20+ | The length of one full rotation. |

| limit.detect.decelonly | Axis | Yes | 6.06+ | Deceleration used when stopping after a limit sensor has triggered. |

| limit.detect.maxspeed | Axis | Yes | 6.06+ | Maximum speed used when moving away from a limit sensor. |

| limit.home.action | Axis | Yes | 6.06+ | Automatic limit switch action. |

| limit.home.edge | Axis | Yes | 6.06+ | Sensor edge to align action to. |

| limit.home.pos | Axis | Yes | 6.06+ | The updated position of the sensor, when triggered. |

| limit.home.posupdate | Axis | Yes | 6.06+ | Position update to occur when sensor is triggered. |

| limit.home.preset | Axis | Yes | 6.06+ | The default position of the home sensor. |

| limit.home.state | Axis | No | 6.06+ | The state of the home sensor. |

| limit.home.triggered | Axis | No | 6.06+ | Whether the home sensor has been triggered previously. |

| limit.home.type | Axis | Yes | 6.06+ | The type of home sensor connected. |

| limit.away.action | Axis | Yes | 6.06+ | Automatic limit switch action. |

| limit.away.edge | Axis | Yes | 6.06+ | Sensor edge to align action to. |

| limit.away.pos | Axis | Yes | 6.06+ | The updated position of the sensor, when triggered. |

| limit.away.posupdate | Axis | Yes | 6.06+ | Position update to occur when sensor is triggered. |

| limit.away.preset | Axis | Yes | 6.06+ | The default position of the away sensor. |

| limit.away.state | Axis | No | 6.06+ | The state of the home sensor. |

| limit.away.triggered | Axis | No | 6.06+ | Whether the away sensor has been triggered previously. |

| limit.away.type | Axis | Yes | 6.06+ | The type of away sensor connected. |

| limit.c.action | Axis | Yes | 6.06+ | Automatic limit switch action. |

| limit.c.edge | Axis | Yes | 6.06+ | Sensor edge to align action to. |

| limit.c.pos | Axis | Yes | 6.06+ | The updated position of the sensor, when triggered. |

| limit.c.posupdate | Axis | Yes | 6.06+ | Position update to occur when sensor is triggered. |

| limit.c.preset | Axis | Yes | 6.06+ | The default position of the c limit sensor. |

| limit.c.state | Axis | No | 6.06+ | The state of the c limit sensor. |

| limit.c.triggered | Axis | No | 6.06+ | Whether the c limit sensor has been triggered previously. |

| limit.c.type | Axis | Yes | 6.06+ | The type of c limit sensor connected. |

| limit.d.action | Axis | Yes | 6.06+ | Automatic limit switch action. |

| limit.d.edge | Axis | Yes | 6.06+ | Sensor edge to align action to. |

| limit.d.pos | Axis | Yes | 6.06+ | The updated position of the sensor, when triggered. |

| limit.d.posupdate | Axis | Yes | 6.06+ | Position update to occur when sensor is triggered. |

| limit.d.preset | Axis | Yes | 6.06+ | The default position of the d limit sensor. |

| limit.d.state | Axis | No | 6.06+ | The state of the d limit sensor. |

| limit.d.triggered | Axis | No | 6.06+ | Whether the d limit sensor has been triggered previously. |

| limit.d.type | Axis | Yes | 6.06+ | The type of d limit sensor connected. |

| limit.max | Axis | Yes | 6.06+ | The maximum position the device can move to, measured in microsteps. |

| limit.min | Axis | Yes | 6.06+ | The minimum position the device can move to, measured in microsteps. |

| limit.start.pos | Axis | Yes | 6.19+ | Start up position of the axis. |

| limit.swapinputs | Axis | Yes | 6.06+ | Reverses the limit positions by swapping the home and away sensors. |

| lockstep.numgroups | Device | No | 6.15+ | The number of lockstep groups provided on the device. |

| lockstep.tolerance | Axis | Yes | 6.15+ | The maximum twist distance between axes in a lockstep group before a stop and untwist occurs. |

| maxspeed | Axis | Yes | 6.06+ | The maximum speed the device moves at. |

| motion.accelonly | Axis | Yes | 6.06+ | Sets the acceleration used to increase the speed. |

| motion.decelonly | Axis | Yes | 6.06+ | Sets the deceleration used when decreasing the speed. |

| motion.index.dist | Axis | Yes | 6.21+ | The distance between consecutive index positions. |

| motion.index.num | Axis | No | 6.22+ | The current index number. |

| peripheralid | Axis | Yes | 6.06+ | The ID of the connected peripheral. |

| peripheral.serial | Axis | Yes | 6.24+ | The serial number of the attached peripheral. |

| pos | Axis | Yes | 6.06+ | The current absolute position of the device. |

| resolution | Axis | Yes | 6.06+ | Microstep resolution |

| stream.numbufs | Device | No | 6.14+ | The number of stream buffers provided in the device. |

| stream.numstreams | Device | No | 6.14+ | The number of streams provided in the device. |

| system.access | Device | Yes | 6.06+ | Sets the access level of the user. |

| system.axiscount | Device | No | 6.06+ | The number of axes in the device. |

| system.current | Device | No | 6.06+ | The current being drawn by the device and motors. |

| system.led.enable | Device | Yes | 6.06+ | Enables the front panel LEDs. |

| system.serial | Device | No | 6.15+ | The serial number of the device. |

| system.temperature | Device | No | 6.06+ | The current temperature of the unit, in degrees Celsius. |

| system.voltage | Device | No | 6.06+ | The voltage being applied to the device. |

| version | Device | No | 6.06+ | The firmware version of the device. |

| version.build | Device | No | 6.17+ | The build number of the device’s firmware. |

| virtual.numvirtual | Device | No | 6.18+ | Number of virtual axes. |

Message Format

The protocol uses a command-reply model, such that:

- Communication must be initiated by a user sending a device a command.

- The device always responds with one reply immediately after a command has been received (except the case mentioned in the Message IDs section below).

- Unless explicitly enabled, a device will not send any message other than a reply to a command.

The content of the message is space-delimited, with consecutive spaces being treated as a single space. There is only one command or response per message. Sending multiple commands in a single message is not supported. See the Message IDs section below for an alternate message format option.

Commands

Commands are sent from the user to one or more devices, which always and immediately respond with a Reply. The data field in the command is case sensitive, space-delimited and depends on the command being executed. See the Command Reference for all the available commands.

A command instructs the device to perform an operation. A typical command message and associated fields are:

- /1 1 move abs 10000↵

- /n a xxxx yyy yyyyy[:CC]ff

- / - Message Type

- Length: 1 byte.

- The message type for a command is always /.

- This field, and the footer, are the only required fields, all others are optional.

- n - Device Address

- Length: 1+ bytes.

- The address indicates which device number should perform the command. The address is optional and if left out, or set to zero, the command is executed by all devices on the chain. Device addresses range from 1 - 99 inclusive.

- Examples of acceptable addresses are:

- 0, 00, 1, 01, 000001, 76, 99, 0x00, 0x01, 0x5A, 0x5a

- Invalid addresses include:

- 100, -1, 0x65 - The addresses are out of range and while the message may be valid, no device will respond.

- a - Axis Number

- Length: 1 bytes.

- The axis number indicates which axis within a device should perform the command. The axis number is optional and if left out, or set to zero, the command is executed by all axes in the device. Axis numbers range from 0 - 9 inclusive.

- xxxx... - Command

- Length: Variable.

- Message data containing command information. The contents are space-delimited.

- The Command Reference below covers the available commands.

- yyy... - Command Parameters

- Length: Variable.

- Message data containing command parameters and data, the contents are space-delimited.

- Numerical values can be in decimal, or hexadecimal when prefixed with 0x.

- Negative values are prefixed with '-'; positive values may optionally be prefixed with '+'.

- The Command Reference below covers the contents of the parameters field for the available commands.

- CC - Message Checksum

- Length: 3 bytes.

- If provided, the device will reject messages that have been corrupted during transmission.

- More information and code examples are provided in the Checksumming section below.

- ff - Message Footer

- Length: 1 - 2 bytes.

- A newline, typically achieved by pressing enter or return. For convenience, the device accepts any ASCII combination of carriage return (CR, \r) and/or line feed (LF, \n) as a message footer.

Smallest Command

The smallest valid command is just /↵ which generates a response from all devices in the chain, as demonstrated below:

- /↵

- @01 0 OK IDLE -- 0

- @03 0 OK IDLE -- 0

- @02 0 OK IDLE -- 0

This can be used as a quick way to check that communications and all devices are functioning as expected.

Longest Command

The maximum command length is 80 characters, including the / and ↵. Devices will not respond to commands longer than this.

Replies

A reply is sent by the device as soon as it has received a command and determined if it should respond. A typical response message and associated fields are:

- @01 0 OK IDLE -- 0↵

- @nn a fl bbbb ww x[:CC]ff

- @ - Message Type

- Length: 1 byte.

- This field always contains @ for a reply message.

- nn - Device Address

- Length: 2 bytes.

- This field contains the address of the device sending the reply, always formatted as two digits.

- a - Axis Number

- Length: 1 byte.

- This field contains the reply scope, from 0 to 9. 0 indicates that the following fields apply to the whole device and all axes on it, otherwise the fields apply to the specific axis indicated.

- fl - Reply Flag

- Length: 2 bytes.

- The reply flag indicates if the message was accepted or rejected and can have the following values:

- OK - The command was valid and accepted by the device.

- RJ - The command was rejected. The data field of the message will contain one of the following reasons:

- AGAIN - The command cannot be processed right now. The user or application should send the command again. Occurs only during streamed motion.

- BADAXIS - The command was sent with an axis number greater than the number of axes available.

- BADCOMMAND - The command or setting is incorrect or invalid.

- BADDATA - The data provided in the command is incorrect or out of range.

- BADMESSAGEID - A message ID was provided, but was not either -- or a number from 0 to 99.

- DEVICEONLY - An axis number was specified when trying to execute a device only command.

- FULL - The device has run out of permanent storage and cannot accept the command. Occurs when storing to a stream buffer or when saving commands to joystick keys.

- LOCKSTEP - An axis cannot be moved using normal motion commands because it is part of a lockstep group. You must use lockstep commands for motion or disable the lockstep group first.

- NOACCESS - The command or setting is not available at the current access level.

- PARKED - The device cannot move because it is currently parked.

- STATUSBUSY - The device cannot be parked, nor can certain settings be changed, because it is currently busy.

- bbbb - Device Status

- Length: 4 bytes.

- This field contains BUSY when the axis is moving and IDLE otherwise. All movement commands, including stop, put the axis into the BUSY state, while they are being executed. During streamed motion, wait commands are considered to be busy, not idle. If the reply message applies to the whole device, the status is BUSY if any axis is busy and IDLE if all axes are idle.

- ww - Warning Flag

- Length: 2 bytes.

- Contains the highest priority warning currently active for the device or axis, or -- under normal conditions. A full description of the flags is available in the Warning Flags Section.

- xxx.. - Response Data

- Length: 1+ bytes.

- The response for the command executed. The contents and format of this field vary depending on the command, but is typically 0 (zero).

- CC - Message Checksum

- Length: 3 bytes.

- A device will append a checksum to all replies if the comm.checksum setting is configured to 1. More information and code examples are provided in the Checksumming section below.

- ff - Message Footer

- Length: 2 bytes.

- This field always contains a CR-LF combination (\r\n) for a reply message.

Replies on Multi axis Devices

For replies with an axis number of 0, the status and warning flags apply to the whole device. If any axis on the device is moving, then the reply status will be busy. Similarly the warning flags show the highest warning across all axes.

For replies with an axis number of 1 or above, the status and warning flags only apply to the axis indicated.

Warning Flags

A warning flag is provided in each device-to-user reply message, indicating whether any device fault or warning is active. If more than one condition is active, it shows the one with highest precedence.

There are three categories of warning flags:

- Fault: Flags in this category indicate an event that has immediate consequences to the behaviour of the device. As a result, the device may have deviated from its trajectory or stopped.

- Warning: Flags in this category indicate that continued operation may lead to unexpected behaviour.

- Note: Flags in this category indicate that an event should be noted by the user before continued operation, but is part of normal device operation.

The warning flags are defined as follows, with the highest priority first:

- FD Fault - Driver Disabled

- The driver has disabled itself due to overheating.

- This warning persists until the driver returns to normal operating conditions.

- On a voice coil axis, this will occur if driver.temperature exceeds 70°C. Once the axis has cooled, send system reset to re-enable the driver.

- FQ Fault - Encoder Error

- The encoder-measured position may be unreliable. The encoder has encountered a read error due to poor sensor alignment, vibration, dirt or other environmental conditions. A home operation is recommended to recalibrate encoder reference position.

- If a controller is set with a peripheral ID of a peripheral with a direct encoder, this flag may appear when the peripheral is not connected. Send system reset after connecting the peripheral to clear the warning.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- Please contact Zaber's technical support if this error persists.

- FS Fault - Stalled and Stopped

- Stalling was detected and the axis has stopped itself.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- FT Fault - Excessive Twist

- The lockstep group has exceeded allowable twist and has stopped.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- FB Fault - Stream Bounds Error

- A previous streamed motion could not be executed because it failed a precondition (e.g. motion exceeds device bounds, calls nested too deeply).

- The error reason can be obtained using the stream info command.

- This warning persists until acknowledged and cleared by the user with the warnings command; also, until the warning is cleared, no further streamed motions can be sent to the failed stream.

- FP Fault - Interpolated Path Deviation

- Streamed or sinusoidal motion was terminated because an axis slipped and thus the device deviated from the requested path.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- FE Fault - Limit Error

- The target limit sensor cannot be reached or is faulty.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- WH Warning - Device not homed

- The device has a position reference, but has not been homed. As a result, calibration has been disabled. Home the device to re-enable calibration.

- This warning persists until the device has been homed.

- WL Warning - Unexpected Limit Trigger

- A movement operation did not complete due to a triggered limit sensor. This flag is set if a movement operation is interrupted by a limit sensor and the No Reference Position (WR) warning flag is not present. This may be an indication that the axis has slipped or one of limit.min and limit.max is incorrect.

- This warning persists until acknowledged and cleared by the user with the warnings command.

- WP Warning - Invalid calibration type

- The saved calibration data type for the specified peripheral.serial value is unsupported by the current peripheralid.

- This warning persists until a valid combination of calibration data, peripheralid, and peripheral.serial is provided.

- WV Warning - Voltage Out of Range

- The supply voltage is outside the recommended operating range of the device. Damage could result to the device if not remedied.

- This warning persists until the condition is remedied.

- WT Warning - Controller Temperature High

- The internal temperature of the controller has exceeded the recommended limit for the device.

- This warning persists until the over temperature condition is remedied.

- WM Warning - Displaced when Stationary

- While not in motion, the axis has been forced out of its position.

- This warning persists until the axis is moved.

- WR Warning - No Reference Position

- Axis has not had a reference position established.

- This warning persists until the axis position is updated via homing or any command/action that sets position.

- NC Note - Manual Control

- Axis is busy due to manual control via the knob.

- This warning persists until a movement command is issued.

- NI Note - Command Interrupted

- A movement operation (command or manual control) was requested while the axis was executing another movement command. This indicates that a movement command did not complete.

- This warning persists until a movement command is issued when the axis is either idle or executing a manual control movement.

- ND Note - Stream Discontinuity

- The device has slowed down while following a streamed motion path because it has run out of queued motions.

- This warning persists until the stream has enough motions queued that it no longer needs to decelerate for that reason, or until the stream is disabled.

- NU Note - Setting Update Pending

- A setting is pending to be updated or a reset is pending.

- This warning is cleared automatically, once the settings have been updated or the device has reset.

- NJ Note - Joystick Calibrating

- Joystick calibration is in progress. Moving the joystick will have no effect.

- This warning persists until joystick calibration is complete.

- NB Note - Firmware Update Mode

- The device is in Firmware Update mode. The firmware is either being updated, or the update was interrupted.

- If you see this warning and the device is not being updated, try updating firmware through Zaber Console.

- The warning persists until the update is successfully completed and the device resumes normal operation.

To see and clear all current warnings, use the warnings command.

Info

This message type contains extra information from the device for testing/debugging/programming purposes. One or more info messages can follow a reply or alert message. This message type is designed to be read by the user and to be ignored by software.

A typical info message and its fields are:

- #01 0 Visit www.zaber.com for instruction manuals.↵

- #nn a xxxxxxxxxxxxx...[:CC]ff

- # - Message Type

- Length: 1 byte.

- This field always contains # for an info message.

- nn - Device Address

- Length: 2 bytes.

- This field contains the address of the device sending the reply, always formatted as two digits.

- a - Axis number.

- Length: 1 byte.

- Always 0 for info messages.

- xxx.. - Data

- Length: 1+ bytes.

- The data for the info message, typically human readable text.

- CC - Message Checksum

- Length: 3 bytes.

- A device will append a checksum to all info messages if the comm.checksum setting is configured to 1. More information and code examples are provided in the Checksumming section below.

- ff - Message Footer

- Length: 2 bytes.

- This field always contains a CR-LF combination (\r\n) for a info message.

The common occurrence of info messages is in reply to a help command, e.g.:

/1 help↵ @01 0 OK IDLE WR 0 #01 0 COMMAND USAGE: #01 0 '/stop' stop all devices #01 0 '/1 stop' stop device number 1 #01 0 '/1 2 stop' stop device number 1 axis number 2 #01 0 #01 0 Type '/help commands' for a list of all top-level commands. #01 0 Type '/help reply' for a quick reference on reply messages. #01 0 Visit www.zaber.com/support for complete instruction manuals.

Alerts

An alert message is sent from a device when a motion command has completed.

If it is enabled, this message can be sent at any time without being preceded by a command from the user. This message type is used for informational purposes or time-sensitive operations.

Alerts are controlled by the comm.alert setting, which has to be 1 for the device to send status alerts.

A typical alert message and its fields are:

- !01 1 IDLE --↵

- !nn a ssss ww[:CC]ff

- ! - Message Type

- Length: 1 byte.

- This field always contains ! for an alert message.

- nn - Device Address

- Length: 2 bytes.

- This field contains the address of the device sending the alert, always formatted as two digits.

- a - Axis Number

- Length: 1 byte.

- ssss - Device status.

- Length: 4 bytes.

- This field contains BUSY when the axis is moving and IDLE when the axis is stopped.

- ww - Warning flags.

- Length: 2 bytes.

- Contains the highest priority warning currently active for the axis, or -- under normal conditions. A full description of the flags is available in the Warning Flags Section.

- CC - Message Checksum

- Length: 3 bytes.

- A device will append a checksum to all alert messages if the comm.checksum setting is configured to 1. More information and code examples are provided in the Checksumming section below.

- ff - Message Footer

- Length: 2 bytes.

- This field always contains a CR-LF combination (\r\n) for an alert message.

Multi axis Alerts

On a multi axis device with completion alerts enabled, an alert will be generated each time an axis stops. In the example below, axis 2 is closer to its maximum position than axis 1 is:

/move max↵ @01 0 OK BUSY -- 0 !01 2 IDLE -- !01 1 IDLE --

The first alert is generated when axis 2 stops, and as that axis is idle, the axis-scope reply has IDLE in its ssss field, even though the device as a whole is still busy due to axis 1 moving. The second alert is generated when axis 1 stops.

Lockstep

When a lockstep set becomes idle, only one alert is generated. The axis number corresponds to the primary axis of the set (axis1 specified in the setup enable command).

Command Reference

The following section details all commands that are available in the ASCII protocol. For specific device support of a command, please refer to that device's User Manual.

For commands with a device scope, specifying an axis number other than zero in the command will result in a DEVICEONLY error, as shown below:

/1 tools parking park↵ @01 0 OK IDLE -- 0 /1 0 tools parking park↵ @01 0 OK IDLE -- 0 /1 1 tools parking park↵ @01 1 RJ IDLE -- DEVICEONLY

For commands with an axis scope, specifying an axis number of zero or not including any axis number will both apply the command to all axes on the device. If one of the axes is unable to complete the command, a BADDATA response will be returned and none of the axes will perform the command. For example, moving to a position that is outside the range of one axis, but within for another axis will result in an error:

/1 get limit.max↵ @01 0 OK IDLE -- 3038763 6062362 /1 move abs 4750000↵ @01 0 RJ IDLE -- BADDATA

Parameters in square brackets, e.g. [clr], indicate that the parameter is optional. Parameters in italics, e.g. value, indicate that data, typically a number, needs to be provided. Parameters separated by a pipe, e.g. abs|rel, indicate that one of the parameters in the set needs to be provided.

calibration

Configure linear encoder calibration.

Linear encoder devices are shipped with pre-loaded calibration data which is applied to the device by default. This can be verified by checking that calibration.type is set to 1. Most users will not need to configure this calibration data. Please contact Zaber's technical support if you need to load, print, or delete calibration data.

estop

Instantly stops motorized movement.

- Scope

- Axis

- Parameters

- none

- Firmware Versions

- 6.06+

The axis ignores the deceleration setting, immediately stops driving the motion, and holds the current position. If the axis is part of a lockstep group, all axes in the group will stop.

Example Usage:

- /1 1 estop↵

- @01 1 OK BUSY -- 0

NOTE: The axis remains powered and will respond to future movement commands.

NOTE: Excessive use of this command may result in potential damage to the product and reduced lifespan. Use sparingly if axis is under heavy load.

force

Applies a constant or sinusoidal force to a voice coil device.

- Scope

- Axis

- Parameters

- abs value

- sin amplitude period [count]

- sin stop

- off

- Firmware Versions

- 6.25+

value and amplitude are unitless measures of force.

abs sets the constant force applied by the axis of value. When applying a constant force, the axis device status will show as IDLE. Setting a constant force while a sinusoidal force is being applied will adjust where the sinusoid is centered. Value must be in the range of [ -700, 700 ].

sin adds a sinusoidal force to any existing constant force output. If the axis is in position control, force.average will be set as the constant force.

- Amplitude specifies half of the peak-to-peak force applied in the sinusoidal force application. The starting and ending force of a complete cycle is always the constant force in effect. A positive amplitude implies that the sinusoidal force starts in the positive direction. A negative amplitude implies that the sinusoidal force starts in the negative direction. Amplitude must be in the range of [ -700, -1 ] or [ 1 , 700 ].

- Period specifies the period of the sinusoid in ms, with resolution of 0.1 ms. A minimum value of 1 ms is recommended to achieve a reasonable resolution. Period must be in the range [ 0.2, 429496729.5 ].

- Count, an optional parameter, specifies the number of repeated cycles. After it completes, the constant force will still continue. If count is not provided, the application will continue until another command interrupts it. To stop the sinusoidal force application after the current cycle completes, refer to the

force sin stopcommand. Count can be in the range [ 1, 4294967294 ].

- The force output is described by

- If the maximum possible force output would be exceeded during the sinusoid, the maximum force will be output during these ranges.

sin stop ends a sinusoidal force when its current cycle completes. After it completes, the constant force will still continue. If the axis is not in a force sin, the command is rejected with response data of NOTSIN.

off removes all current to the motor, pre-empting any force or move commands. If the axis is stationary in position control mode, the position will no longer be actively maintained.

Example Usage:

Apply force in the positive direction:

- /force abs 200↵

- @01 0 OK IDLE -- 0

Apply sinusoidal force at 10Hz, centered at a constant force of 300. After 50 cycles, the axis will remain at a constant force of 300:

- /force abs 300↵

- @01 0 OK IDLE -- 0

- /force sin 200 100 50↵

- @01 0 OK BUSY -- 0

Remove all force output:

- /force off↵

- @01 0 OK IDLE -- 0

get

Retrieves the current value of the device or axis setting.

- Scope

- Device and Axis

- Parameters

- setting The name of one of the Device Settings.

- Firmware Versions

- 6.06+

See Device Settings for a detailed list or settings and what they do.

Example Usage:

Viewing the device ID:

- /get deviceid↵

- @01 0 OK IDLE -- 20022

- Device ID is 20022 (A-LSQ150B)

Viewing an invalid setting:

- /get cloop.mode↵

- @01 0 RJ IDLE -- BADCOMMAND

- cloop.mode is only valid on devices with encoders, and this device does not have one. Attempting to read an invalid setting results in a BADCOMMAND rejection reply.

help

Displays the built-in help.

- Scope

- Device

- Parameters

- [commands|reply|warnflags|enums|command|enum]

- Firmware Versions

- 6.06+

Displays the help information for the system, commands, replies, warning flags, enumerations, or a specific command and enumeration as applicable. This command will always return a successful reply and the help information will be returned in info messages.

help reply displays information about the reply message format.

help warnflags displays information about the warning flags that can be present in a reply.

help enums displays a list of enumerations that can be present in command parameters.

As the built-in help is specific to each device, a device number is required when sending the command. Issuing a help command without a device number will result in each device in the chain requesting that a device number be specified, as shown below:

- /help↵

- @01 0 OK IDLE -- 0

- #01 0 Please provide a device address for querying help

- @02 0 OK IDLE -- 0

- #02 0 Please provide a device address for querying help

Example Usage:

View the built-in help for the estop command

- /1 help estop↵

- @01 0 OK IDLE -- 0

- #01 0 estop Emergency stop

Help for an invalid command returns successfully:

- /1 help dlkjsfbi↵

- @01 0 OK IDLE -- 0

- #01 0 No help found

home

Moves the axis to the home position.

- Scope

- Axis

- Parameters

- none

- Firmware Versions

- 6.06+

The axis is moved towards the home position (closest to the motor generally) at the lesser of the limit.approach.maxspeed and maxspeed settings. Once the home position is reached, the current position is reset to the limit.home.preset. Additionally, limit.home.triggered is set to 1, and the No Reference Position (WR) warning flag is cleared. This command is equivalent to tools gotolimit home neg 2 0.

Example Usage:

- /home↵

- @01 0 OK BUSY WR 0

NOTE: Upon power up or setting changes, this command should be issued to obtain a reference position. Otherwise, motion commands may respond with a rejection reply or behave unexpectedly.

io info

Returns the number of I/O channels the device has.

- Scope

- Device

- Parameters

- [ao|ai|do|di]

- Firmware Versions

- 6.06+

The parameters are used to specify the channel type: ai for Analog Input, ao for Analog Output, di for Digital Input and do for Digital Output. Channel numbers start at 1 for each type.

If the channel type is not specified, all channels will be returned in the following order: analog out, analog in, digital out, digital in

Example Usage:

Getting the available io configuration:

- /io info↵

- @01 0 OK IDLE -- 0 4 4 4

- Device has no analog outputs, 4 analog input channels, 4 digital outputs and 4 digital inputs.

Getting the configuration of a specific port type:

- /io info ao↵

- @01 0 OK IDLE -- 0

- Device has no analog output capabilities

Invalid port type:

- /io info as↵

- @01 0 RJ IDLE -- BADCOMMAND

io get

Get the current value of the specified I/O channel type.

- Scope

- Device

- Parameters

- ao|ai|do|di [channel]

- Firmware Versions

- 6.06+

If channel isn't specified a space-delimited list of all channels of the requested type are returned.

For digital channels, a value of 0 indicates that the input or output is not conducting and a value of 1 indicates that the channel is conducting.

For analog channels, the value returned is a measurement of the voltage present on the input with enough decimal places to cover the available resolution. To see the available resolution, please consult the Series Specs Tab on the device Product Page.

Example Usage:

Reading an analog input:

- /io get ai 2↵

- @01 0 OK IDLE -- 7.5

- Analog input 2 has 7.5V on it

Reading all digital outputs:

- /io get do↵

- @01 0 OK IDLE -- 0 0 1 0

- Digital output 3 is high while the rest are low.

Invalid port type:

- /io get as 0↵

- @01 0 RJ IDLE -- BADCOMMAND

Invalid channel number, using the available channels from the io info command above:

- /io get ai 5↵

- @01 0 RJ IDLE -- BADDATA

- /io get ao↵

- @01 0 RJ IDLE -- BADDATA

- The analog output port has no channels and can't be displayed.

io set

Sets the specified output.

- Scope

- Device

- Parameters

- do channel value

- do port value value2...

- Firmware Versions

- 6.06+

Sets the specified output channel to value.

For digital channels, a value of 0 clears the output while any other value sets it.

Specifying 'port' allows setting of all digital outputs at once.

Example Usage:

Clear digital output 3:

- /io set do 3 0↵

- @01 0 OK IDLE -- 0

Using the port command to set digital output 1, 3, 4 and clear output 2:

- /io set do port 1 0 1 1↵

- @01 0 OK IDLE -- 0

Invalid port type:

- /io set ad 2 50↵

- @01 0 RJ IDLE -- BADCOMMAND

Port type that's not an output or has no channels:

- /io set ai 2 50↵

- @01 0 RJ IDLE -- BADDATA

- /io set ao 2 50↵

- @01 0 RJ IDLE -- BADDATA

Invalid channel number:

- /io set do 8 1↵

- @01 0 RJ IDLE -- BADDATA

joystick

Configures joystick axes.

- Scope

- Device

- Parameters

- 1|2|3 target device axis

- 1|2|3 target device lockstep index

- 1|2|3 target device virtual index

- 1|2|3 speedprofile 1|2|3

- 1|2|3 maxspeed max

- 1|2|3 invert 0|1

- 1|2|3 resolution steps

- 1|2|3 info

- calibrate limits|deadbands start|save

- Firmware Versions

- 6.16+

Axis Configuration

The joystick commands allow the user to configure each axis of the joystick. For each axis, there are five parameters that can be modified:

- target configures which device and axis the joystick axis controls. It is also possible to use the target command to specify a lockstep group or virtual axis.

- speedprofile specifies how the velocity of the target device should scale with joystick deflection:

- 1 - Linear

- 2 - Squared (factory default)

- 3 - Cubed

- maxspeed specifies the speed the target device will move at the maximum deflection of the joystick axis.

- invert specifies the direction the target device moves when the joystick axis is deflected. When invert is set to 0 (the default value):

- Joystick axis 1 - left is negative and right is positive.

- Joystick axis 2 - down is negative and up is positive.

- Joystick axis 3 - counter-clockwise is negative and clockwise is positive.

- resolution sets the number of discrete steps in each direction at which a new velocity is sent. A higher resolution will result in higher sensitivity. The maximum number of steps possible is the lesser of maxspeed and ~500 (exact value depends on joystick calibration).

Example Usage:

Setting the joystick's left-right axis to control axis 1 of device 2:

- /1 joystick 1 target 2 1↵

- @01 0 OK IDLE -- 0

Setting axis 2 of the joystick to control lockstep group 1 on device 3:

- /1 joystick 2 target 3 lockstep 1↵

- @01 0 OK IDLE -- 0

Setting axis 3 of the joystick to control virtual axis 1 on device 3:

- /01 joystick 3 target 3 virtual 1↵

- @01 0 OK IDLE -- 0

Changing the velocities to scale linearly with joystick deflection for joystick axis 2:

- /1 joystick 2 speedprofile 1↵

- @01 0 OK IDLE -- 0

Setting the maximum speed for joystick axis 3 to 200000:

- /1 joystick 3 maxspeed 200000↵

- @01 0 OK IDLE -- 0

Switching the direction that turning the joystick handle moves the target axis from default:

- /1 joystick 3 invert 1↵

- @01 0 OK IDLE -- 0

Reducing the sensitivity of joystick axis 3 by reducing the number of discrete steps in each direction to 20:

- joystick 3 resolution 20↵

- @01 0 OK IDLE -- 0

Displaying Joystick Axis Information

The info command causes the joystick to return a list of space-separated values which are, in order:

- The joystick axis' target (either device number and axis number, or device number, lockstep, and lockstep index for a lockstep group)

- The target maxspeed

- The target speed profile

- The invert state

- The number of discrete steps in each direction of the joystick's motion

Example Usage:

- /1 joystick 1 info

- @01 0 OK IDLE -- 2 1 10000 2 1 50↵

- /1 joystick 2 info

- @01 0 OK IDLE -- 3 lockstep 1 10000 2 0 50↵

- /01 joystick 3 info↵

- @01 0 OK IDLE -- 3 virtual 1 10000 2 0 50↵

Joystick Calibration

Zaber's joysticks are calibrated before shipping, and we do not recommend re-calibrating unless you encounter problems such as motion occurring while the joystick is in the neutral position, or an inability to reach maximum velocity even with the joystick fully displaced. The calibrate command allows the limits and deadbands of the joystick to be reset. Note that attempting to start calibrating deadbands while calibrating limits (or vice versa) will cause the command to be rejected with BADDATA.

To calibrate limits:

- Send /01 joystick calibrate limits start

- Move joystick all the way to the left and all the way to the right

- Move joystick all the way up and all the way down

- Turn the joystick handle all the way counter-clockwise and all the way clockwise

- Send /01 joystick calibrate limits save↵

To calibrate deadbands:

- Send /01 joystick calibrate deadbands start↵

- Wiggle joystick slightly to the left and right of the neutral position. Try to move only slightly beyond the limits of the slack.

- Wiggle joystick slightly up and down from the neutral position.

- Wiggle joystick handle slightly counter-clockwise and clockwise from the neutral position

- Send /01 joystick calibrate deadbands save↵

key

Configures joystick keys.

- Scope

- Device

- Parameters

- index event add command

- index event alert 0|1

- index event info

- index event clear

- clear all

- Firmware Versions

- 6.16+

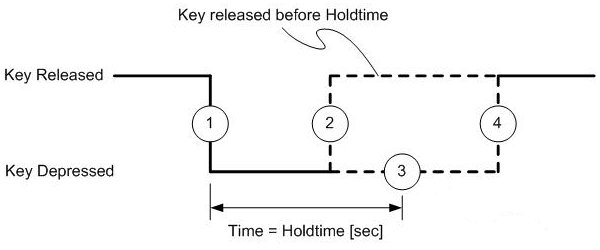

The key commands allow the buttons on the joystick to be programmed. When pressing and releasing a key, there are a series of events that take place depending on how long the key is held. If the key is pressed and released before 1 second, the event sequence is 1-2. If the key is pressed, held for one second or more and then released, the event sequence is 1-3-4 (note that event 3 will be issued after the key is held for 1 second, and event 4 is issued upon release). This is illustrated in the figure below. The hold time of the key cannot be changed by the user.

Saving commands to keys

Each key event can store a list of commands to run. Before saving events to keys, ensure that you have cleared any previously saved commands as shown in the section below.

Note that all commands will be sent in close succession; if multiple movement commands are sent to the same axis, only the last one will complete. If complex motion is required and your target device supports stream commands, save a sequences of motions in a stream buffer on the target device then use a joystick key to call this buffer.

Example usage:

Configure key 2 to send the stop command to all devices when it is held down for a second:

- /1 key 2 3 add 0 stop↵

- @01 0 OK IDLE -- 0

Configure key 4 to call stream buffer 1 on device 2.

- /1 key 4 1 add 2 stream 1 setup disable↵

- @01 0 OK IDLE -- 0

- /1 key 4 1 add 2 stream 1 setup live 1 2↵

- @01 0 OK IDLE -- 0

- /1 key 4 1 add 2 stream 1 call 1↵

- @01 0 OK IDLE -- 0

If the body of the saved command (not including the target device and axis) exceeds 60 characters, the command will be rejected with BADDATA.

Sending key alerts to the computer

Each key event can be configured to send an alert message to a computer via the previous port when it occurs. In order to make use of this functionality, comm.alert must first be set to 1.

Example Usage:

To enable alerts for a particular key event, first enable alerts on your device:

- /1 set comm.alert 1↵

Then, use the key alert command to enable alerts for each desired key event:

- /1 key 2 1 alert 1↵

- @01 0 OK IDLE -- 0

When key 2 is pressed, the following alert will be sent:

- !01 0 key 2 1

To disable the alert, send command data 0 instead:

- /1 key 2 1 alert 0↵

- @01 0 OK IDLE -- 0

Displaying key configuration

Use the info command to display the programmed key events. The reply message indicates whether or not alerts are enabled for that key event. The saved commands are sent as info messages.

Example Usage:

To display information about key 4, event 1:

- /1 key 4 1 info↵

- @01 0 OK IDLE -- alerts disabled

- #01 0 cmd 02 0 stream 1 setup disable

- #01 0 cmd 02 0 stream 1 setup live 1 2

- #01 0 cmd 02 0 stream 1 call 1

Clearing keys

The clear command deletes all commands stored for the specified button and event.

Example Usage:

Clear all saved instructions for a single key event:

- /1 key 4 1 clear↵

- @01 0 OK IDLE -- 00

Clear all commands stored on all keys:

- /1 key clear all↵

- @01 0 OK IDLE -- 00

lockstep

Sets up and controls synchronized motion of a group of parallel axes.

- Scope

- Device

- Parameters

- number setup enable axis1 axis2

- number setup disable

- number info

- number estop

- number home

- number move abs|rel|vel value

- number move min|max

- number move stored number

- number stop

- Firmware Versions

- 6.15+

Lockstep commands allow two axes of a device to be driven in lockstep, always at exactly the same speed, suitable for driving the two sides of a parallel gantry mechanism.

Setup

Devices that allow lockstep commands will have a non-zero lockstep.numgroups setting, showing how many simultaneous groups of lockstepped axes you can have on the device. The number of the lockstep group you are addressing is the first number parameter in any of the above lockstep commands. Lockstep commands will only be available on devices with at least 2 axes.

Before mechanically connecting the axes that will be in a lockstep group, home each one individually first. Next, align the system and fasten it together. Once it's mechanically set-up, send the setup enable command with axis1 and axis2 (the axes that will a part of the set) as the data values. Axes can only be in one lockstep group and must be idle when the set is enabled, or the setup enable command will be rejected. The difference between the position values of the axes will be recorded as the offset value (see section below for more information on the offset.)

The set will remain enabled, including through power cycles, and continue to move in lockstep until the setup disable command is sent.

Example Usage:

Initiating paired lockstep movement:

- /01 lockstep 1 setup enable 1 2↵

- @01 0 OK IDLE -- 0

- Axes 1 and 2 are now paired.

Ending paired movement of the axes:

- /01 lockstep 1 setup disable↵

- @01 0 OK IDLE -- 0

- The axes that were paired in lockstep 1 are no longer paired and can move independently again.

Offset, Twist, and Tolerance

Each axis in a lockstep group continues to track its own position (pos setting). Any difference in the position values between axes when the group was enabled is known as the offset value. This is the expected position difference, and the system will try to maintain this difference throughout movement commands as both axes are driven together.

Conditions may arise where the axes don't move together perfectly though. Some examples are if one of the axes slips or stalls during motion, if an external force is applied to one of the axes, if the stages become out of alignment, or if there's an obstruction in the movement of one axis. The unexpected component of the difference in positions that's created between the axes is called twist.

Without position feedback, the amount of twist can't be detected or corrected for. Because of this, it's strongly recommended to build systems using closed-loop devices with integrated encoders so that the amount of twist can be managed.

There are two methods the controllers use to correct for twist. Firstly, they will move to untwist immediately before executing any lockstep movements, including move commands, manual movement, and displacement recovery. To untwist, axis2 will move to make the correction (unless this would move axis2 outside its limits, in which case the axis1 will move.)

The second correction is to stop movement if the twist exceeds a certain value, defined by the lockstep.tolerance setting of axis2. If cloop.mode is 4 (stall recovery) or above, the controller will untwist the axes and resume movement. Otherwise, the axes are stopped and the warning flag FT is set. The lockstep.tolerance value is 0 by default, which is a special value that allows unlimited twist during movements. The acceptable tolerance of the system should be set by the user depending on the construction of the system, including the length between axes, loading, stiffness of the system, and error tolerance.

Both of the above corrections require the closed-loop mode to include position correction (cloop.mode setting of 3 or higher). All of the other closed-loop mode functions that would normally apply to an axis (stall detection, recovery, etc.) will continue to apply.

Use Caution if you are using the set pos command with a lockstep group enabled. Any difference in positions other than the offset amount will be treated as twist, even if it's a result of changing the position setting, and the stage will try to correct it with the next movement command. If the position values do not match the offset plus any actual twist in the mechanical system, it will likely introduce mechanical twist in the system when they try to correct.

After a power cycle, one of the axes will be at its limit.max position on power-up while the positions of the others will be based on the offset values. This will enforce the normal constraint of only being able to retract the system until it's reached a reference position. The twist value will not be retained through a power cycle though. To keep track of the twist through a power-cycle, use the tools parking commands.

Information

To read out information about an active lockstep group, use the lockstep info command. This command returns a list of space-separated values which are, in order:

- the axis number used to set axis1

- the axis number used to set axis2

- the offset value of the axis2 compared to axis1

- the current twist value of axis2 compared to axis1

Example Usage:

Requesting info for a lockstep group with two axes:

- /01 lockstep 1 info↵

- @01 0 OK IDLE -- 1 2 525 0

- In this case axis1 corresponds to is axis 1 and axis2 (corresponding to axis 2) is offset 525 microsteps from it. There is currently no twist between the axes.

Response if lockstep group has not been enabled:

- /01 lockstep 1 info↵

- @01 0 OK IDLE -- disabled

Movement

When a lockstep group of devices is enabled, you can no longer address movement commands to the individual axes in the group, with the exception of stop and estop. Instead, all of the standard movement commands have lockstep equivalents that can be sent to the device, including the move commands, home, stop, and estop. Each of these commands will cause both axes to execute the movement together. A stop or estop command issued to all axes or an individual axis in the group will stop all axes in the group.

Movement commands that require a reference position, such as move abs or move stored, will use the axis1 position for reference. To store a position to move to, you would address tools storepos commands to the axis used for axis1.

The most restrictive position (limit.min, limit.max), speed (maxspeed), and acceleration (accel) limit settings of all axes in the group will be applied to lockstep motion commands. For example if axis 1 has a maxspeed setting of 20000 and an accel setting of 205 and axis 2 has a maxspeed of 10000 and an accel of 300, their lockstep motion would accelerate at 205 to a top speed of 10000.

Example Usage:

Sending lockstep movement commands to a lockstep group:

- /01 lockstep 1 move vel 10000↵

- @01 0 OK BUSY -- 0

- /01 lockstep 1 stop↵

- @01 0 OK BUSY -- 0

Sending non-lockstep movement commands to an axis in a lockstep group:

- /01 lockstep 1 setup enable 1 2↵

- @01 0 OK IDLE -- 0

- /01 1 move abs 1000↵

- @01 0 RJ IDLE -- LOCKSTEP

- The move abs command will be rejected and LOCKSTEP will be returned because only lockstep movement commands are allowed for axes in a lockstep group.

Maximum limits of all axes are enforced:

- /01 lockstep 1 info↵

- @01 0 OK IDLE -- 1 2 500 0

- /01 get limit.max↵

- @01 0 OK IDLE -- 300000 300000

- /01 lockstep 1 move abs 300000↵

- @01 0 RJ IDLE -- BADDATA

- The move abs command will be rejected and BADDATA returned because an absolute movement of 30000 would exceed the limit.max of axis 2 by the offset value of 500.

Homing and Sensors

When the lockstep home command is sent to a group, they will retract together until any home sensor is detected. Once the home sensor of an axis is detected, the group will follow the actions for that home sensor, including setting the pos of that axis to its limit.home.preset. The offset values of other axes in the group will be used to set the positions of those axes. In some cases this could put the pos setting of an axis outside of its position limit range, in which case the lockstep group will only be able to move towards the violated limit until the position of the axis is back within range.

Similarly if any other sensor is detected during operation, the lockstep group will follow the actions prescribed by that sensors settings, and update the positions of other axes based on their relative offsets. The limit.sensor.posupdate setting of a sensor will only be applied to the sensor's axis, and will not change the limits of other axes.

move

Moves the device to various positions along its travel.

- Scope

- Axis

- Parameters

- abs|rel|vel value

- min|max

- stored number

- index number

- sin amplitude period [count]

- sin stop

- Firmware Versions

- 6.06+

- move index: 6.21+

- move sin: 6.22+

value is in units of microsteps.

abs moves to the absolute position of value. Value must be in the range [ limit.min, limit.max ].

rel moves the axis by value microsteps, relative to the current position. Value must be in the range [ limit.min - pos, limit.max - pos ].

vel moves the axis at the velocity specified by value until a limit is reached. Value must be in the range [ -resolution * 16384, resolution * 16384 ].

min moves the axis to the minimum position, as specified by limit.min.

max moves the axis to the maximum position, as specified by limit.max.

stored moves the axis to a previously stored position. Number specifies the stored position number, from 1 - 16. Refer to the tools storepos command for more information.

index moves the axis to an index position. For a provided number, this command directs the axis to move to the absolute position (number - 1) * motion.index.dist. Note that only positive values of number are accepted.

- For rotary devices with a non-zero limit.cycle.dist, the command will be accepted if the targeted position is greater or equal to 0 and less than limit.cycle.dist. The device will move either clockwise or counter-clockwise, depending on which direction yields the shortest distance to the target position. If you want all index positions to be equally spaced around the circle, set motion.index.dist to a factor of limit.cycle.dist.

- For linear devices, or rotary devices where limit.cycle.dist is zero, the command will be accepted if the targeted position is within the valid travel of the device, i.e. in the range [ limit.min, limit.max ].

The target speed of the above motion commands is specified by either the value parameter to vel or the maxspeed setting. The actual speed is calculated as (speed / 1.6384) microsteps/sec.

sin starts a sinusoidal motion.

- Amplitude specifies half of the peak-to-peak amplitude of the motion in units of microsteps. A positive number implies that the sinusoidal motion starts at the minimum position and will move in a positive direction from the starting position. A negative number implies that the sinusoidal motion starts at the maximum position and will move in a negative direction from the starting position. The starting position of the device and the other limit of the sinusoidal motion (current position + amplitude * 2) must both be in the range [ limit.min, limit.max ] .

- Period specifies the period of the motion in ms, with resolution down to 0.1 ms. A minimum value of 1 ms is recommended to achieve a reasonable resolution. Period must be in the range [ 0.2, 429496729.5 ].

- Count, an optional parameter, specifies the number of repeated cycles. The valid range is 1 - 4294967294. If count is not provided, the motion will continue until another motion or stop command pre-empts it. To stop the sinusoidal motion after the current cycle completes, refer to the move sin stop command.

- On stepper motor products with direct reading or linear encoders (i.e. encoder.mode is 2), sinusoidal motion commands can only be executed when cloop.mode is set to 2 or 0.

- The speed and acceleration of a sinusoidal motion are determined by the amplitude and period specified in the command, as shown in the following equation. It is up to the user to ensure the maximum acceleration is low enough to prevent the stage from slipping.

- Note: A sinusoidal motion has limited ability to recover from a stalling condition.

sin stop ends a sinusoidal motion when its current cycle completes.

Example Usage:

Move all axes on the device forward by 200000 microsteps:

- /move rel 200000↵

- @01 0 OK BUSY -- 0

No reference point:

- /move rel 2000000↵

- @01 0 RJ IDLE WR BADDATA

- The WR flag indicates that there is no reference point and the axis has not been homed. Sending the home command will allow the move command to succeed.

Invalid position:

- /get limit.max↵

- @01 0 OK IDLE -- 305381

- /move abs 305888↵

- @01 0 RJ IDLE -- BADDATA

- A bad data rejection was received because the position specified is beyond the range of the axis.

Parked:

- /move abs 10000↵

- @01 0 RJ IDLE -- PARKED

- Axes cannot be moved when the device is parked. Either unpark or home it.

Start a sinusoidal motion to move indefinitely, then stop it at the end of a complete cycle:

- /move sin 200 1000↵

- @01 0 OK BUSY -- 0

- /move sin stop↵

- @01 0 OK BUSY -- 0

Sinusoidal motion rejected due to the device being busy:

- /move vel 20↵

- @01 0 OK BUSY -- 0

- /move sin 200 1000 1↵

- @01 0 RJ BUSY -- STATUSBUSY

renumber

Renumbers a device, or all devices in a chain.

- Scope

- Device

- Parameters

- [value] Valid range: 1 - 99.

- Firmware Versions

- 6.06+

The global version of this command sequentially renumbers all devices in the chain, starting with value, if provided, or 1. The global renumber command only works on interfaces that support daisy chaining; issuing a global renumber command over an interface that doesn't support daisy chaining will be rejected with a BADCOMMAND. Please consult the device User Manual to determine which interfaces support daisy chaining.

When a specific device address is sent the renumber command, the renumber command will change the device number to value (in which case value is required).

When a device receives a renumber command, it will use the new device number for its response.

Example Usage:

Renumbering all devices in the chain:

- /renumber↵

- @01 0 OK IDLE -- 0

- @02 0 OK IDLE -- 0

- The devices renumbered, with the device closest to the computer being at address 1, and the next closest being at address 2.

Renumbering a specific device:

- /2 renumber 4↵

- @04 0 OK IDLE -- 0

- Device 2 renumbered and replied on address 4.

- This is equivalent to /2 set comm.address 4↵

Invalid device number:

- /renumber 999↵

- @01 0 RJ IDLE -- BADDATA

- The requested device number was outside of the allowable range.

NOTE: The device will reply on its new address, not the address the command was sent to.

servo

Configures position control servo tuning of a voice coil device.

- Scope

- Axis

- Parameters

- get param

- set param value

- preset get param

- preset store param

- preset store param value

- preset store all

- load preset

- set default preset

- get default

- Firmware Versions

- 6.25+

While stepper motors have direct position control, voice coil devices are force controlled. These devices require a position feedback control algorithm to achieve accurate positioning. The best algorithm will change based on the loading of the system, so there are a number of parameters that can be set to optimize the performance. The servo commands are used to configure these parameters, including saving, changing, and storing them.

Tuning Parameters

Each of the position control tuning parameters can be queried and adjusted individually via the servo get and servo set commands. These parameters can be adjusted frequently to accommodate different load conditions. However, these parameters apply to this session only and do not persist over a power cycle. To store tuning parameters to non-volatile memory, use one of the servo preset store commands as described in below.

param is one of ae1, be1, bv1, ai1, bi1, ah1, ah2, bh1, bh2, gain, or ilimit.