S-Curve Motion Profiles for Jerk Control

Published on Dec. 23, 2021

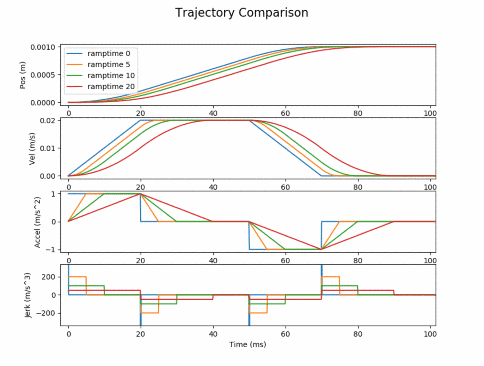

S-curve motion control, also called jerk control or jerk limited motion control, is a form of motion control that limits “jerk”. What is jerk in motion control? In much the same way that acceleration is the rate of change of velocity, jerk is the rate of change of acceleration. Some motion control algorithms apply a constant acceleration and deceleration, which results in a trapezoidal shape when plotting velocity vs. time. An s-curve motion control algorithm varies acceleration gradually, limiting jerk and producing a characteristic "s" shaped curve when plotting velocity vs. time.

Zaber motion devices with firmware version 7.19 and up offer s-curve motion profiles for jerk limited motion. The smoother acceleration transitions of s-curve motion profiles offer many benefits over trapezoidal motion profiles including:

- reduced audible noise and system vibrations

- increased lifetime of drivetrain components such as lead nuts and thrust bearings

- reduced trajectory overshoot for servo devices

These benefits are particularly useful for:

- low vibration applications, such as imaging or inspection

- high throughput applications with many rapid starts and stops

- vertical applications with high drivetrain loading

- low stiffness applications where moment payloads, liquid payloads, or belt driven systems are present

S-curve motion profiles for jerk control can be enabled using the motion.accel.ramptime setting, on all of Zaber’s X-series products with firmware 7.xx. Higher values increase the duration of acceleration transitions, decreasing the amount of jerk. The included image shows a comparison of different setting values for a 1 mm move. For more information visit the firmware 7 ASCII protocol manual or contact us.