Manuals/Binary Protocol Manual

This manual describes the Binary communication protocol for devices with Firmware 6.xx. If your device uses Firmware 5.xx, refer to the individual product manual for specific details on the command set. If your device uses Firmware 7.xx, refer to the Firmware 7 Binary Protocol Manual. For devices with firmware version 6.06 and above, the ASCII Protocol is the recommended method of communication. See Appendix A for how to switch between these protocols.

Quick Start

- Download Zaber Console and install it.

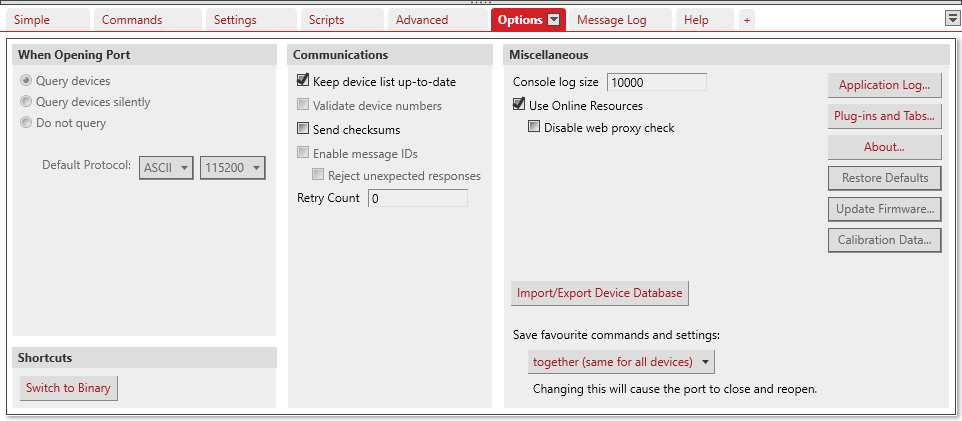

- Select the Serial Port to use and Click the Open button. Check that the serial port shows as Binary.

- If it shows as ASCII, you can either use the devices in ASCII mode, or go to the Options Tab and press 'Switch to Binary'.

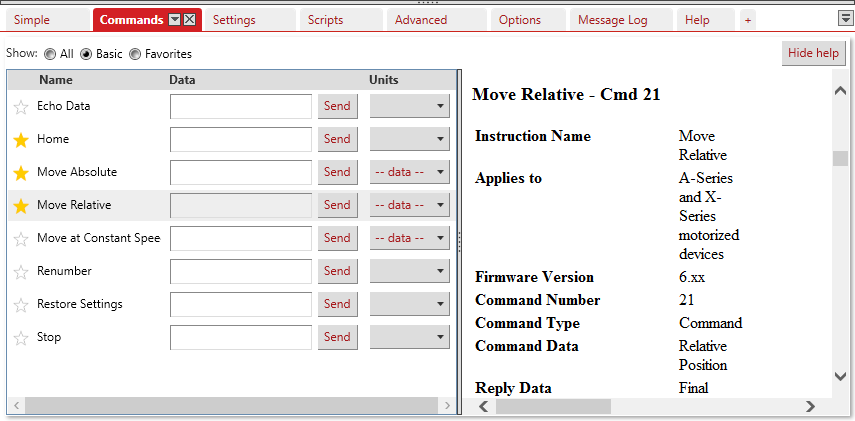

- Switch to the Commands tab:

Serial Port Configuration

All devices using the binary protocol default to the following settings:

- Baud rate: 9600 bits/s

- Data bits: 8

- Parity bit: None

- Stop bit: 1

- Handshake/Flow control: None

Message Format

All instructions consist of a group of 6 bytes. They must be transmitted with less than 10 ms between each byte. If the device has received less than 6 bytes and then a period longer than 10 ms passes, it ignores the bytes already received. We recommend that your software behave similarly when receiving data from the devices, especially in a noisy environment like a pulsed laser lab.

The following table shows the instruction format:

- Byte 1 - Device #

- Byte 2 - Command #

- Byte 3 - Data - Least Significant Byte (LSB)

- Byte 4 - Data

- Byte 5 - Data

- Byte 6 - Data - Most Significant Byte (MSB)

The first byte is the device number in the daisy-chain. Device number 1 is the closest device to the computer and device number 2 is next and so on. If the number 0 is used, all the devices in the chain will process the accompanying command simultaneously. A multi-axis device appears as multiple devices with their own numbers.

The second byte is the command number. Bytes 3, 4, 5, and 6 are data in long integer, 2’s complement format with the least significant byte transmitted first. How the command data are interpreted depends on the command. Complete details are given in the command reference on the following page.

Examples

- All devices renumber: 0, 2, 0, 0, 0, 0

- All devices home: 0, 1, 0, 0, 0, 0

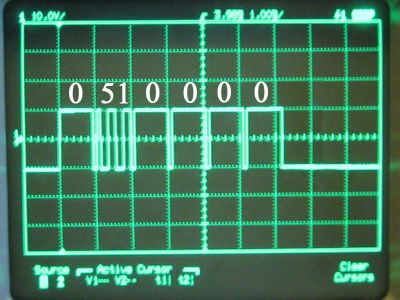

- All devices return firmware version: 0, 51, 0, 0, 0, 0

- Device 1 move to an absolute position (command 20) of 257 microsteps: 1, 20, 1, 1, 0, 0

- Device 2 move to a relative position (command 21) of -1 microstep: 2, 21, 255, 255, 255, 255

Most instructions cause the device to reply with a return code. It is also a group of 6 bytes. The first byte is the device #. Byte #2 is the instruction just completed or 255 (0xFF) if an error occurs. Bytes 3, 4, 5 and 6 are data bytes in the same format as the instruction command data.

Data Conversion Algorithms

If you are writing software to control Zaber products, you'll likely need to generate data bytes 3 through 6 from a single data value, or vise versa. The following pseudo-code can be used as a model.

Converting command data into command bytes to send to Zaber products

If Cmd_Data < 0 then Cmd_Data = 256^4 + Cmd_Data 'Handles negative data Cmd_Byte_6 = Cmd_Data / 256^3 Cmd_Data = Cmd_Data - 256^3 * Cmd_Byte_6 Cmd_Byte_5 = Cmd_Data / 256^2 Cmd_Data = Cmd_Data - 256^2 * Cmd_Byte_5 Cmd_Byte_4 = Cmd_Data / 256 Cmd_Data = Cmd_Data - 256 * Cmd_Byte_4 Cmd_Byte_3 = Cmd_Data

Converting reply bytes into a single reply data value

Reply_Data = 256^3 * Rpl_Byte_6 + 256^2 * Rpl_Byte_5 + 256 * Rpl_Byte_4 + Rpl_Byte_3 If Rpl_Byte_6 > 127 then Reply_Data = Reply_Data - 256^4 'Handles negative data

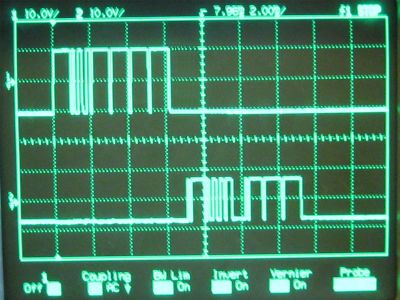

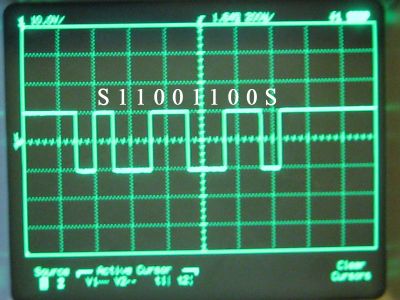

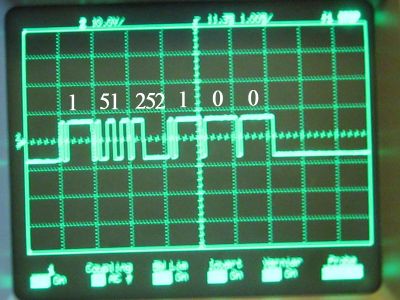

Sample Waveforms

If you are designing hardware to interface with Zaber products, it may be useful to see some sample waveforms.

Quick Command Reference

The following table offers a quick command reference for devices running firmware version 6.00 and above. For convenience, you may sort the table below by instruction name, command number, or reply number. Follow the links to view a detailed description of each instruction.

| Instruction Name | Command# | Command Data | Command Type | Reply Data |

|---|---|---|---|---|

| Reset | 0 | Ignored | Command | None |

| Home | 1 | Ignored | Command | Final position (in this case 0) |

| Renumber* | 2 | Ignored | Command | Device ID |

| Read Register | 5 | Register Address | Command | Data |

| Set Active Register | 6 | Register Address | Setting | Register Address |

| Write Register | 7 | Data | Command | Data |

| Move Tracking | 8 | n/a | Reply | Tracking Position |

| Limit Active | 9 | n/a | Reply | Final Position |

| Manual Move Tracking | 10 | n/a | Reply | Tracking Position |

| Manual Move | 11 | n/a | Reply | Final Position |

| Slip Tracking | 12 | n/a | Reply | Tracking Position |

| Unexpected Position | 13 | n/a | Reply | Final Position |

| Store Current Position* | 16 | Address | Command | Address |

| Return Stored Position | 17 | Address | Command | Stored Position |

| Move To Stored Position | 18 | Address | Command | Final Position |

| Move Absolute | 20 | Absolute Position | Command | Final Position |

| Move Relative | 21 | Relative Position | Command | Final Position |

| Move At Constant Speed | 22 | Speed | Command | Speed |

| Stop | 23 | Ignored | Command | Final Position |

| Set Active Axis* | 25 | Axis | Setting | Axis |

| Set Axis Device Number* | 26 | Device Number | Setting | Device Number |

| Set Axis Inversion* | 27 | Invert Status | Setting | Invert Status |

| Set Axis Velocity Profile* | 28 | Profile Number | Setting | Profile Number |

| Set Axis Velocity Scale* | 29 | Maximum Velocity | Setting | Maximum Velocity |

| Load Event Instruction* | 30 | Key Event | Command | Key Event |

| Return Event Instruction | 31 | Key Event | Command | n/a |

| Set Joystick Calibration Mode | 33 | Calibration Mode | Setting | Calibration Mode |

| Restore Settings* | 36 | Peripheral ID | Command | Peripheral ID |

| Set Microstep Resolution* | 37 | Microsteps | Setting | Microsteps |

| Set Running Current* | 38 | Value | Setting | Value |

| Set Hold Current* | 39 | Value | Setting | Value |

| Set Device Mode* | 40 | Mode | Setting | Mode |

| Set Home Speed* | 41 | Speed | Setting | Speed |

| Set Target Speed* | 42 | Speed | Setting | Speed |

| Set Acceleration* | 43 | Acceleration | Setting | Acceleration |

| Set Maximum Position* | 44 | Range | Setting | Range |

| Set Current Position | 45 | New Position | Setting | New Position |

| Set Home Offset* | 47 | Offset | Setting | Offset |

| Set Alias Number* | 48 | Alias Number | Setting | Alias Number |

| Return Device ID | 50 | Ignored | Read-Only Setting | Device ID |

| Return Firmware Version | 51 | Ignored | Read-Only Setting | Version |

| Return Power Supply Voltage | 52 | Ignored | Read-Only Setting | Voltage |

| Return Setting | 53 | Setting Number | Command | Setting Value |

| Return Status | 54 | Ignored | Read-Only Setting | Status |

| Echo Data | 55 | Data | Command | Data |

| Return Firmware Build | 56 | Ignored | Read-Only Setting | Build Number |

| Return Current Position | 60 | Ignored | Read-Only Setting | Position |

| Return Serial Number | 63 | Ignored | Read-Only Setting | Serial Number |

| Set Park State* | 65 | Park State | Setting | Position |

| Set Peripheral ID* | 66 | Peripheral ID | Setting | Peripheral ID |

| Return Digital Input Count | 67 | Ignored | Read-Only Setting | Pin Count |

| Read Digital Input | 68 | Pin Number | Command | Pin State |

| Read All Digital Inputs | 69 | Ignored | Command | Pin States |

| Return Digital Output Count | 70 | Ignored | Read-Only Setting | Pin Count |

| Read Digital Output | 71 | Pin Number | Command | Pin State |

| Read All Digital Outputs | 72 | Ignored | Command | Pin States |

| Write Digital Output | 73 | See Description | Command | Same as Command Data |

| Write All Digital Outputs | 74 | Pin States | Command | Pin States |

| Return Analog Input Count | 75 | Ignored | Read-Only Setting | Pin Count |

| Read Analog Input | 76 | Pin Number | Command | Voltage |

| Return Analog Output Count | 77 | Ignored | Read-Only Setting | Pin Count |

| Move Index | 78 | Index Number | Command | Final Position |

| Set Index Distance | 79 | Distance | Setting | Distance |

| Set Cycle Distance | 80 | Distance | Setting | Distance |

| Set Filter Holder ID | 81 | Filter Holder ID | Setting | Filter Holder ID |

| Return Encoder Count | 82 | Ignored | Read-Only Setting | Encoder Count |

| Return Calibrated Encoder Count | 83 | Ignored | Read-Only Setting | Calibrated Encoder Count |

| Return Calibration Type | 84 | Ignored | Read-Only Setting | Calibration Type |

| Return Calibration Error | 85 | Ignored | Read-Only Setting | Calibration Error |

| Set Peripheral Serial Number* | 86 | Peripheral Serial Number | Setting | Peripheral Serial Number |

| Force Absolute | 87 | Force | Command | Force |

| Force Off | 88 | Ignored | Command | None |

| Set Auto-Reply Disabled Mode* | 101 | Auto-Reply Mode | Setting | Auto-Reply Mode |

| Set Message ID Mode* | 102 | Message ID Mode | Setting | Message ID Mode |

| Set Home Status | 103 | Home Status | Setting | Home Status |

| Set Home Sensor Type* | 104 | Home Sensor Type | Setting | Home Sensor Type |

| Set Auto-Home Disabled Mode* | 105 | Auto-Home Disabled Mode | Setting | Auto-Home Disabled Mode |

| Set Minimum Position* | 106 | Minimum Position | Setting | Minimum Position |

| Set Knob Disabled Mode* | 107 | Knob Disabled Mode | Setting | Knob Disabled Mode |

| Set Knob Direction* | 108 | Direction | Setting | Direction |

| Set Knob Movement Mode* | 109 | Movement Mode | Setting | Movement Mode |

| Set Knob Jog Size* | 110 | Jog Size | Setting | Jog Size |

| Set Knob Velocity Scale* | 111 | Velocity Scale | Setting | Velocity Scale |

| Set Knob Velocity Profile* | 112 | Velocity Profile | Setting | Velocity Profile |

| Set Acceleration Only* | 113 | Acceleration | Setting | Acceleration |

| Set Deceleration Only* | 114 | Deceleration | Setting | Deceleration |

| Set Move Tracking Mode* | 115 | Tracking Mode | Setting | Tracking Mode |

| Set Manual Move Tracking Disabled Mode* | 116 | Tracking Mode | Setting | Tracking Mode |

| Set Move Tracking Period* | 117 | Tracking Period | Setting | Tracking Period |

| Set Closed-Loop Mode* | 118 | Closed-Loop Mode | Setting | Closed-Loop Mode |

| Set Slip Tracking Period* | 119 | Tracking Period | Setting | Tracking Period |

| Set Stall Timeout* | 120 | Timeout | Setting | Timeout |

| Set Device Direction* | 121 | Direction | Setting | Direction |

| Set Baud Rate* | 122 | Baud Rate | Setting | Baud Rate |

| Set Protocol* | 123 | Protocol | Setting | Protocol |

| Convert To Ascii* | 124 | Baud Rate | Command | Baud Rate |

| Error | 255 | n/a | Reply | Error Code |

* The settings for these commands are saved in non-volatile memory, i.e. the setting persists even if the device is powered down. To restore all settings to factory default, use command 36.

Command Reference

Reset - Cmd 0

| Instruction Name | Reset |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 0 |

| Command Type | Command |

| Command Data | Ignored |

| Reply Data | None |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Sets the device to its power-up condition. |

This has the same effect as unplugging and restarting the device.

Special Note

For firmware 6.16 and above, after the Reset (Cmd 0) command is sent the device will wait to reset until the communication lines have been idle for 500ms. For firmware 6.15 and below, after the Reset (Cmd 0) command is sent the device will reset as soon as the communication lines are idle.

The position of the device will be lost upon reset. If it is important to keep the same position, Park the stage before resetting/powering down and Unpark the stage afterwards to recover the position settings (See Set Park State (Cmd 65) command).

All non-volatile settings (i.e. Device Number, Target Velocity, etc.) are saved and are not affected by reset or power-down.

Home - Cmd 1

| Instruction Name | Home |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 1 |

| Command Type | Command |

| Command Data | Ignored |

| Reply Data | Final Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Moves to the home position and resets the device's internal position. |

Upon receiving this instruction, the device will retract until its internal home sensor is triggered. It will then move forward several steps to avoid accidentally re-triggering the home sensor during use. Its internal position is then reset (to 0 for most devices). If a home offset has been specified with the Set Home Offset (Cmd 47) instruction, the device will move forward for the specific offset, then reset the internal position.

The device will attempt to home for an extended amount of time. If Closed-Loop Mode is enabled for an encoder-embedded device, the device will report any slip or stall incident.

NOTE: The device will attempt to move towards the home sensor regardless of the Minimum Position and Home Offset settings. Set Minimum Position (Cmd 106) does not prevent the device from moving pass the Minimum Position during Homing. If you need to initialize the device without homing it, Park the stage before power down and Unpark the stage when power is restored. See Set Park State (Cmd 65) for details.

Renumber - Cmd 2

| Instruction Name | Renumber |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 2 |

| Command Type | Command |

| Command Data | New Number |

| Reply Data | Device ID |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Assigns new numbers to all the devices in the order in which they are connected. |

This command is usually sent to device number 0. When it is, the command data is ignored and all devices will renumber. The device closest to the computer becomes device number 1. The next device becomes number 2 and so on.

If sent to a device number other than 0, then that device will reassign itself the device number in the command data. Valid device numbers are 1-99 for version 6.05, and 1-254 otherwise.

Note: Renumbering takes about 1/2 a second during which time the computer must not send any further data. The device number is stored in non-volatile memory so you can renumber once and not worry about issuing the renumber instruction again after each power-up.

Read Register - Cmd 5

| Instruction Name | Read Register |

|---|---|

| Applies to | A-Series and X-Series devices |

| Firmware Version | 6.xx |

| Command Number | 5 |

| Command Type | Command |

| Command Data | Register Address |

| Reply Data | Data |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Reads from a register. |

This command reads the data value from a register location.

NOTE: This command is meant for Zaber's internal use. Do not use this command unless directed to by Zaber technical support.

Set Active Register - Cmd 6

| Instruction Name | Set Active Register |

|---|---|

| Applies to | A-Series and X-Series devices |

| Firmware Version | 6.xx |

| Command Number | 6 |

| Command Type | Setting |

| Command Data | Register Address |

| Reply Data | Register Address |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Sets the active register. |

This command sets the address of the active register. When a device receives a Write Register (Cmd 7) command, data is written to the active register.

NOTE: This command is meant for Zaber's internal use. Do not use this command unless directed to by Zaber technical support.

Write Register - Cmd 7

| Instruction Name | Write Register |

|---|---|

| Applies to | A-Series and X-Series devices |

| Firmware Version | 6.xx |

| Command Number | 7 |

| Command Type | Command |

| Command Data | Data |

| Reply Data | Data |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Writes to a register. |

This command writes the data to the active register. The active register is specified by Set Active Register (Cmd 6).

NOTE: This command is meant for Zaber's internal use. Do not use this command unless directed to by Zaber technical support.

Store Current Position - Cmd 16

| Instruction Name | Store Current Position |

|---|---|

| Applies to | All motorized devices |

| Firmware Version | 5.04 and up |

| Command Number | 16 |

| Command Type | Command |

| Command Data | Address |

| Reply Data | Address |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Saves the current absolute position of the device. |

Valid Address values are 0 through 15 specifying one of 16 possible registers in which to store the position. This command can only be executed when the device has been homed. This command is used in conjunction with the Return Stored Position (Command #17) and Move To Stored Position (Command #18) instructions. The positions stored in the position registers are non-volatile and will persist after power-down or reset. All position registers are cleared by the Restore Settings (Command #36) instruction.

Return Stored Position - Cmd 17

| Instruction Name | Return Stored Position |

|---|---|

| Applies to | All motorized devices |

| Firmware Version | 5.04 and up |

| Command Number | 17 |

| Command Type | Command |

| Command Data | Address |

| Reply Data | Stored Position |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the position stored in one of the 16 position registers for the device. |

Valid command data values are 0 through 15, specifying one of 16 possible registers from which to retrieve the position. This command is used in conjunction with the Store Current Position (#16) and Move To Stored Position (#18) commands. Positions stored in the position registers are non-volatile and will persist after power-down or reset. All position registers are cleared by the Restore Settings (#36) command.

Move To Stored Position - Cmd 18

| Instruction Name | Move To Stored Position |

|---|---|

| Applies to | All motorized devices |

| Firmware Version | 5.04 and up |

| Command Number | 18 |

| Command Type | Command |

| Command Data | Address |

| Reply Data | Final Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Moves the device to the stored position specified by the Command Data. |

Valid address values are 0 through 15, specifying one of 16 possible positions. This command is used in conjunction with the Store Current Position (#16) and Return Stored Position (#17) commands. This command does not send a response until the move has finished. All move commands are pre-emptive. If a new move command is issued before the previous move command is finished, the device will immediately move to the new position.

The target speed and acceleration during a move absolute instruction can be specified using Set Target Speed (Cmd 42) and Set Acceleration (Cmd 43) respectively.

This command may pre-empt, or be pre-empted by Move to Stored Position (Cmd 18), Move Absolute (Cmd 20), Move Relative (Cmd 21), Move at Constant Speed (Cmd 22), Move Index (Cmd 78) and Stop (Cmd 23).

Move Absolute - Cmd 20

| Instruction Name | Move Absolute |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 20 |

| Command Type | Command |

| Command Data | Absolute Position |

| Reply Data | Final Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Moves the device to the position specified in the Command Data in microsteps. |

The device begins to move immediately, and sends a response when the move has finished. The position must be between Minimum and Maximum Position (specified by Set Minimum Position (Cmd 106) and Set Maximum Position (Cmd 44)), or an error code will be returned.

The target speed and acceleration during a move absolute instruction can be specified using Set Target Speed (Cmd 42), Set Acceleration (Cmd 43), Set Acceleration Only (Cmd 113) and Set Deceleration Only (Cmd 114).

All move commands are pre-emptive. If a new move command is issued before the previous move command is finished, the device will immediately move to the new position. This command may pre-empt, or be pre-empted by Move to Stored Position (Cmd 18), Move Absolute (Cmd 20), Move Relative (Cmd 21), Move at Constant Speed (Cmd 22), Move Index (Cmd 78) and Stop (Cmd 23).

Move Relative - Cmd 21

| Instruction Name | Move Relative |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 21 |

| Command Type | Command |

| Command Data | Relative Position |

| Reply Data | Final Position |

| Safe to retry? | No |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Moves the device by the positive or negative number of microsteps specified in the Command Data. |

The device moves to a position given by its current position plus the value specified in the command data. The relative move command data in microsteps can be positive or negative. The final position must be between Minimum and Maximum Position (specified by Set Minimum Position (Cmd 106) and Set Maximum Position (Cmd 44)), or an error code will be returned. The device begins to move immediately, and sends a response when the move has finished.

The target speed and acceleration during a move absolute instruction can be specified using Set Target Speed (Cmd 42), Set Acceleration (Cmd 43), Set Acceleration Only (Cmd 113) and Set Deceleration Only (Cmd 114).

All move commands are pre-emptive. If a new move command is issued before the previous move command is finished, the device will immediately move to the new position. If a Move Relative command is issued while the device is currently moving due to a previous command, the device will immediately set a new target position equal to the current position (at the instant the command was received) plus the specified relative position.

This command may pre-empt, or be pre-empted by Move to Stored Position (Cmd 18), Move Absolute (Cmd 20), Move Relative (Cmd 21), Move at Constant Speed (Cmd 22), Move Index (Cmd 78) and Stop (Cmd 23).

Move At Constant Speed - Cmd 22

| Instruction Name | Move At Constant Speed |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 22 |

| Command Type | Command |

| Command Data | Speed |

| Reply Data | Speed |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Moves the device at a constant speed based on the value specified in the Command Data. |

This instruction specifies a direction and a speed to move, rather than a target position. When this instruction is issued the device will accelerate to the speed specified by the instruction data. The device will continue moving at this speed until a limit is reached or a pre-empting instruction is issued. Negative speeds cause retraction while positive speeds cause extension. Unlike the other movement commands, this command sends a response immediately without waiting for the move to finish.

If the device reaches minimum or maximum position (specified by Set Minimum Position (Cmd 106) and Set Maximum Position (Cmd 44)), the device stops and the new position is returned via reply-only command Limit Active (Cmd 9).

The device accelerates/decelerates at a rate specified by Set Acceleration (Cmd 43), Set Acceleration Only (Cmd 113) and Set Deceleration Only (Cmd 114).

The device may be set to return its position continually during the move using Set Move Tracking Mode (Cmd 115).

This command may pre-empt, or be pre-empted by Move to Stored Position (Cmd 18), Move Absolute (Cmd 20), Move Relative (Cmd 21), Move at Constant Speed (Cmd 22), Move Index (Cmd 78) and Stop (Cmd 23).

For a spreadsheet that can be used to calculate speed setting values for any product see https://www.zaber.com/documents/ZaberSpeedSetting.xls. Alternatively you may use the formulas below.

Actual Speed

- = Data / 1.6384 * M mm/s or deg/s

- = Data / 1.6384 microsteps/s

- = Data / 1.6384 / R steps/s

- = Data / 1.6384 / (R x S) * 60 revolutions/min Motor rpm

- = Data / 1.6384 * L / (R x S) mm/s Linear devices only

where:

- Data is the value of the command data

- R (microsteps/step) is the microstep resolution (command 37)

- S (steps/revolution) is the number of steps per motor revolution

- M (mm or deg) is the microstep size

- L (mm or deg) is the distance of linear motion per motor revolution

Refer to product specifications for the distance corresponding to a single microstep or revolution.

For example, if a motor has 200 steps per revolution (S = 200), used with default resolution (R = 64), and Data is 251658, then the motor will move at a speed of 720 revolutions per minute.

Valid data values are from (−16384×R) to (16384×R). Note that a value of zero will cause the device to decelerate to a stop and then send Limit Active (Cmd 9).

Stop - Cmd 23

| Instruction Name | Stop |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 23 |

| Command Type | Command |

| Command Data | Ignored |

| Reply Data | Final Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Stops the device from moving by preempting any move instruction. |

This instruction can be used to pre-empt any move instruction. The device will decelerate to a stop. The reply data is the absolute position after stopping.

Rate of deceleration can be specified by either Set Acceleration (Cmd 43) (sets both Acceleration and Deceleration) or Set Deceleration Only (Cmd 114) (sets Deceleration only).

Depressing the manual control knob also gives the same effect as this command.

If another Stop is issued during deceleration (either by this command or depressing the manual control knob), the device will instantly stop.

This command may pre-empt, or be pre-empted by Move to Stored Position (Cmd 18), Move Absolute (Cmd 20), Move Relative (Cmd 21), Move at Constant Speed (Cmd 22), Move Index (Cmd 78) and Stop (Cmd 23).

Set Active Axis - Cmd 25

| Instruction Name | Set Active Axis |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 25 |

| Command Type | Setting |

| Command Data | Axis |

| Reply Data | Axis |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the active axis. |

Only one axis can be active at a time, therefore each axis has to be set individually. The settings for each axis are stored in non-volatile memory, and will persist after powering down or resetting. To determine the joystick's current active axis issue the return settings command #53 with a command data value of 25.

Valid Command Data values are:

- 1 (Axis 1)

- 2 (Axis 2)

- 3 (Axis 3)

Subsequent changes to any axis settings will apply only to the active axis.

Settings for the active axis can be changed using the commands shown here:

- Set Axis Device Number (Command #26)

- Set Axis Inversion (Command #27)

- Set Axis Velocity Profile (Command #28)

- Set Axis Velocity Scale (Command #29)

| Axis # | Positive Direction | Negative Direction |

|---|---|---|

| Axis 1 | right | left |

| Axis 2 | up | down |

| Axis 3 | clockwise | counter-clockwise |

Example: To set the maximum velocity of axis number 2 follow the steps below:

- Issue the Set Active Axis command #25 with a command data value of 2 to make axis number 2 the active axis.

- Then issue the Set Axis Velocity Scale (Command #29) using the desired maximum velocity as the command data value. All subsequent "Set Axis..." commands will also apply to the axis number 2 until the user sets a different axis to be the active axis.

Set Axis Device Number - Cmd 26

| Instruction Name | Set Axis Device Number |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 26 |

| Command Type | Setting |

| Command Data | Device Number |

| Reply Data | Device Number |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the device number to be controlled using the active axis. |

Note: This setting affects only the active axis. See the Set Active Axis Command #25 for instructions on how to select an axis.

Valid command data values for setting an axis device number range between 0 and 254. Once a axis device number is set, the setting is stored in non-volatile memory and will persist after power-down or reset.

To restore the joystick to its factory default settings, issue a Restore Settings Command #36. The factory default settings for axis control are as follows:

- Axis #1 controls Device #2

- Axis #2 controls Device #3

- Axis #3 controls Device #4

Example: Suppose you would like to assemble a 3-axis system where:

- Joystick axis 1 (right / left) controls device #3.

- Joystick axis 2 (up / down) controls device #4.

- Joystick axis 3 (clockwise / counterclockwise) controls device #2.

First, connect the joystick and the three additional devices. For installation instructions please view the X-JOY3 installation section of the manual.

Issue the Renumber Command #2 from the computer. After renumbering (less than 1 second) the joystick will become device #1, and the remaining devices will become devices #2, #3, and #4. Now commands may be issued to the joystick to set the desired behavior. The command sequence is as follows:

- Device:1 Cmd:25 Data:1 - Set Axis # 1 to be the active axis.

- Device:1 Cmd:26 Data:3 - Set the active axis (#1) to control device #3.

- Device:1 Cmd:25 Data:2 - Set Axis # 2 to be the active axis. (Settings for each axis need to be set individually)

- Device:1 Cmd:26 Data:4 - Set active axis (#2) to control device #4.

- Device:1 Cmd:25 Data:3 - Set Axis # 3 to be the active axis.

- Device:1 Cmd:26 Data:2 - Set the active axis (#3) to control device #2.

Note: All commands are being sent to device #1 (joystick). This is because the 3 downstream devices will be controlled by the joystick. Setting axis number and directions must be done by changing the joystick settings, not the individual device settings.

Special Note: It is possible to have one axis control 2 or more devices. All of the devices on this axis will move together. Follow the steps below to set more than one device on a single axis:

- For each device you wish to control on one axis, set the device alias number with Command #48. Selecting an alias number much larger than the device numbers in use will help to differentiate between aliases and devices (Ex: 99). The alias number must be the same for each device you wish to control with a single axis.

- Issue the Set Active Axis Command #25 with command data equal to the axis number you wish to use.

- Issue the Set Axis Device Number Command #26 with command data equal to the alias number you selected.

Set Axis Inversion - Cmd 27

| Instruction Name | Set Axis Inversion |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 27 |

| Command Type | Setting |

| Command Data | Invert Status |

| Reply Data | Invert Status |

| Safe to retry? | No |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Inverts the active joystick axis. |

Sometimes it is desirable to invert one or more axes to create a more intuitive user interface. The Set Axis Inversion (#27) command allows the user to set the invert status of the active axis. Use Invert Status = 1 to set the current axis to non-inverted, use Invert Status = -1 to set the current axis to inverted. Use Invert Status = 0 to toggle between invert and non-invert (the Invert Status of the reply will still be either 1 or -1).

See the Set Active Axis (#25) instruction for information on how to select an axis. Each axis can be inverted independently of the other two axes.

Here are the default directions for each axis (not inverted):

- On axis 1, left is negative and right is positive.

- On axis 2, down is negative and up is positive.

- On axis 3, counter-clockwise is negative and clockwise is positive.

What constitutes positive or negative motion depends on the device; see the user’s manual for the device in question. The default axis inversion setting for all joystick axes is non-inverted.

For example, to invert joystick axis 2:

- Device:1 Cmd:25 Data:2 - Set Axis # 2 to be the active axis. (Settings for each axis need to be set individually)

- Device:1 Cmd:27 Data:-1 - Set active axis (#2) to be inverted (positive and negative directions switch).

Set Axis Velocity Profile - Cmd 28

| Instruction Name | Set Axis Velocity Profile |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 28 |

| Command Type | Setting |

| Command Data | Profile Number |

| Reply Data | Profile Number |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the relationship between the angle of the active joystick axis and the velocity of the device. |

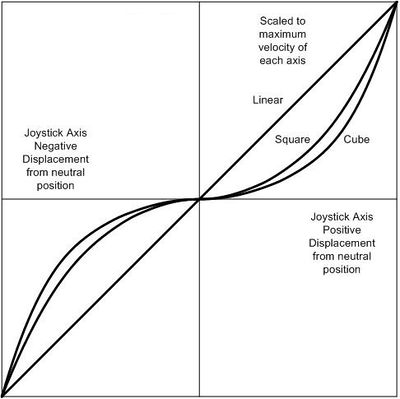

When the joystick is displaced from the neutral position, it reads the angular position and calculates how fast and in which direction the corresponding devices should be instructed to move. There are three different velocity profile numbers that can be requested:

- 1 – Linear

- 2 – Squared (factory default)

- 3 – Cubed

The maximum velocity is set by the Set Axis Velocity Scale (#29) command. Squared and cubed curves offer finer control at slow speeds, but still allow maximum velocity when the joystick is fully deflected.

Set Axis Velocity Scale - Cmd 29

| Instruction Name | Set Axis Velocity Scale |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 29 |

| Command Type | Setting |

| Command Data | Maximum Velocity |

| Reply Data | Maximum Velocity |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the velocity scale of the active axis. |

The data represents the desired maximum velocity corresponding to full displacement of the joystick. When the joystick is moved away from the neutral position, the displacement is translated into Move At Constant Velocity instruction which is sent to the device associated with the displaced axis. See the user’s manual for the device in question for more information on the Move At Constant Velocity instruction.

The velocity scale setting works in conjunction with the velocity profile setting. See the Set Axis Velocity Profile (#28) command for more detail.

Setting the velocity scale to 0 will disable the active axis. This prevents the joystick from sending any instructions in response to displacement of that axis. This is useful when the user wants to execute a program from the computer, and does not want the joystick to be accidentally moved.

The default velocity scale for all three axes is 44880.

Load Event Instruction - Cmd 30

| Instruction Name | Load Event Instruction |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 30 |

| Command Type | Command |

| Command Data | Key Event |

| Reply Data | Key Event |

| Safe to retry? | No |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Loads the next instruction as the event-triggered instruction specified in the Command Data. |

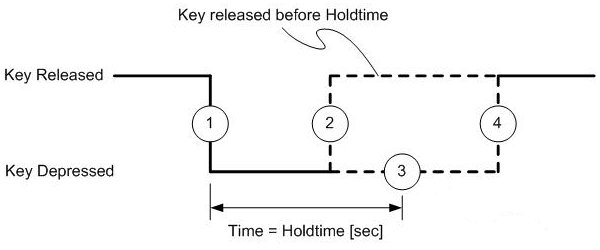

When pressing and releasing a key (button on the X-JOY3), there are a series of events that take place depending on how long the key is held. If the key is pressed and released before 1 second, the event sequence is 1-2. If the key is pressed, held for one second or more and then released, the event sequences is 1-3-4 (note that event 3 will be issued after the key is held for 1 second, and event 4 is issued upon release). This is illustrated in the figure below. The hold time of the key cannot be changed by the user.

Each key event can be programmed to issue only one instruction. The instruction written to an event can be different for each key. You can also set an event to do nothing by issuing a echo command for that event.

When programming a joystick key, we recommend disconnecting all of the devices connected to the joystick. When a command is loaded to the key it is also sent to the connected devices and may cause unexpected movement. On a side note, it is important to know that when a command is issued it is sent to all devices. Only the devices that the command is addressed to will actually perform that command, and all of the other devices will ignore it.

If you are using message IDs we recommend that you disable them when programming the joystick. That way the programmed instructions will work whether the target device has message IDs enabled or not.

To program an instruction to a key event please follow these steps:

1. Send a Load Event Instruction Command #30 to the device # corresponding to the joystick, with a two digit command data value, where the first digit is the key number and the second digit is the event number. This command tells the device which key and event you would like to program an instruction for.

Example: If you want to program event #2 of Key #3 you would issue a Load Event Instructions command with a data value of 32.

2. Now that you have issued a Load Event Instruction command, The device is waiting for you to issue an instruction. At this point in time the Load Event Instruction command is volatile and will not persist after powering down (This means if you power down you will need to issue another Load Event Instruction command before sending the event instruction). The command that you issue now will be programmed to the key and event you specified in step 1. This command can be issued normally, and can be addressed to any device connected to and including the joystick.

Note: After issuing the command you wish to program, there will be no feedback (light, beep etc.) indicating you have correctly programmed the button. The response screen will only say that a command has been issued. If you see that your command has been issued immediately after the load instruction response then you have most likely correctly programmed the key. The best test is to manually test the key to see if it performs your command.

3. Now you have finished programming one event on a key. The instruction programmed to that key is now non-volatile and will persist after powering down. Repeat the steps above to continue programming events to keys. To set an event to do nothing, issue an Echo Data command to device number 255 for that event.

Important: Be sure to program all of the events each time you program a key. The key events may have instructions already programmed into them therefore you will have to program an event to either do nothing, or perform the command you want it to do. If you do not do this pressing a key could cause a device or joystick to do something unexpected. A list of the default settings can be found in the X-JOY3 User Manual.

Key Event Programming Examples

Example 1: Programming a key to stop and home a single device.

In this example we will use device #3 as the device we want address the instructions to. Device #1 is the Joystick. We will program these instructions to key #4. We want device #3 to home when the key is pushed and held for 1 second and we want it to stop when the key is pushed and released before 1 second. The home instruction will be programmed to event number 3 and the stop instruction will be programmed to event number 2.

To program the device, follow the instructions listed below:

| Device# | Command | Cmd# | Cmd Data | Description |

|---|---|---|---|---|

| 1 | Load Event Instuction | 30 | 42 | This command prepares the joystick key for instruction, the command data number 42 means that you are directing this instruction towards key #4 and event #2. |

| 3 | Stop | 23 | 0 | Because this command is being issued immediately after the Load Event Instruction (#30) it will be programmed to event #2 at key #4. |

| 1 | Load Event Instruction | 30 | 43 | This command prepares the joystick key for instruction, the command data number 43 means that you are directing this instruction towards key#4 and event #3. |

| 3 | Home | 1 | 0 | Because this command is being issued immediately after the Load Event Instruction (#30) it will be programmed to event #3 at key#4. |

Example 2: Disable/Enable an Axis

In this example we will be disabling Axis #1. This axis usually controls device #2. The way that we are going to disable the axis is by reassigning the axis device number. This way the instruction will be sent to a device that will ignore a move command (the Joystick). We will be programming key #5. The key will disable the axis when pressed and released before 1 second and enable the axis when pressed, held for one second or more and then released.

To program the device, follow the instructions below:

| Device# | Command | Cmd# | Cmd Data | Description |

|---|---|---|---|---|

| 1 | Load Event Instruction | 30 | 51 | This command prepares the joystick so that key #5 at event #1 can be programmed. |

| 1 | Set Active Axis | 25 | 1 | This command makes the axis active so that its device number can be changed. It is loaded to event number 1 so that the axis will become active as soon as the key is pressed. |

| 1 | Load Event Instruction | 30 | 52 | This command prepares the joystick so that key #5 at event #2 can be programmed. |

| 1 | Set Axis Device Number | 26 | 1 | This causes the axis to control the joystick, however all of the move commands sent to the joystick will be ignored. Therefore moving this joystick axis will not cause motion. |

| 1 | Load Event Instruction | 30 | 53 | This command prepares the joystick so that key #5 at event #3 can be programmed. |

| 1 | Set Axis Device Number | 26 | 2 | This command causes the axis to now control device number 2. This will enable the axis again by setting it to control Device #2, as before. |

Return Event Instruction - Cmd 31

| Instruction Name | Return Event Instruction |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 31 |

| Command Type | Command |

| Command Data | Key Event |

| Reply Data | n/a |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the the event-triggered instruction associated with the key-event. |

See the Load Event-Triggered Instruction (#30) for more information on definition of key events and event-triggered instructions.

To return the event-triggered instruction associated with a particular key event, issue the Return Event Instruction (#31) command to the joystick with data as follows:

- Command Data = Key * 10 + Trigger

Where:

- Key is a number from 1 to 5 corresponding to the key location

- Event is a number from 1 to 4 corresponding to the key event

The reply will be comprised of the device, command and data of the event-triggered instruction associated with the specified key event. Note that as far as the computer is concerned, the reply will appear to come from whatever device the event-triggered instruction is addressed to, which may not be the joystick. We recommend that all additional devices be disconnected from the joystick before loading or returning event-triggered instructions to avoid confusion.

Set Joystick Calibration Mode - Cmd 33

| Instruction Name | Set Joystick Calibration Mode |

|---|---|

| Applies to | X-JOY3 |

| Firmware Version | 6.16 and up |

| Command Number | 33 |

| Command Type | Setting |

| Command Data | Calibration Mode |

| Reply Data | Calibration Mode |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Calibrates the joystick by adjusting the limits and the deadbands. |

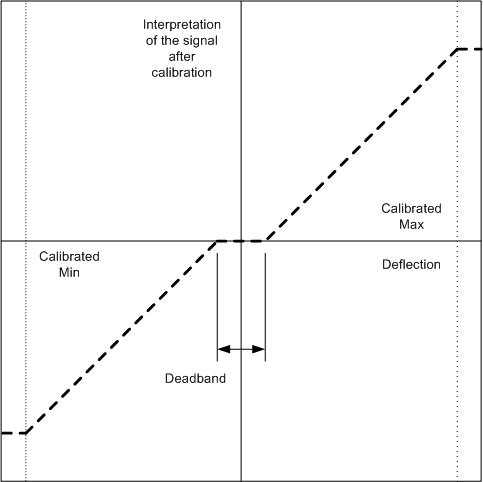

There are two sets of calibration variables: limits and deadbands. Limits define the maximum angular displacement of all axes of manipulation. Deadbands define the area around the neutral position of the joystick where no action should occur. Deadbands are useful to adjust the sensitivity of the joystick to vibration or accidental movement from the neutral position. Acceptable Calibration Mode values are: 0, 1, or 2. Mode 1 is for calibrating the maximum limits. Mode 2 is for calibrating the deadbands. Mode 0 exits the calibration routine.

The joystick is pre-calibrated before shipping so that it should work well right out of the box. Note that restoring default settings using command #36 will have no affect on the joystick calibration. There is no default calibration since each joystick has slightly different properties that prevent a single set of settings from working well on all devices.

The joystick should work well as calibrated. We do not recommend re-calibrating it unless you encounter problems such as motion occurring while the joystick is in the neutral position, or an inability to reach maximum velocity even with the joystick fully displaced.

To calibrate the limits, follow these steps:

- Issue command 33, data 1 to put joystick in “calibrate limits” mode

- Move joystick all the way to the left and all the way to the right

- Move joystick all the way up and all the way down

- Turn joystick knob all the way counter-clockwise and all the way clockwise

- Issue command 33, data 0 to save the measured limit parameters

To calibrate the deadbands, follow these steps:

- Issue command 33, data 2 to put joystick in “calibrate deadbands” mode

- Wiggle joystick slightly to the left and right of the neutral position. Try to move only within the limits of the slack. Do not move past the point where resistance begins.

- Wiggle joystick slightly up and down from the neutral position

- Turn joystick knob slightly counter-clockwise and clockwise from the neutral position

- Issue command 33, data 0 to save the measured limit parameters

Restore Settings - Cmd 36

| Instruction Name | Restore Settings |

|---|---|

| Applies to | A-Series and X-Series Devices |

| Firmware Version | 6.xx |

| Command Number | 36 |

| Command Type | Command |

| Command Data | 0 or Peripheral ID |

| Reply Data | 0 or Peripheral ID |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Restores the device settings to the factory defaults. |

This instruction is very useful for troubleshooting. If the device does not appear to function properly, it may be because some of the settings have been changed. This instruction will restore the settings to default values. All settings affected by this instruction are stored in non-volatile memory and will persist after power-down or reset.

A-Series and X-Series devices with an integrated controller will only accept a data value of 0.

Note: For A-Series and X-Series controllers, when used with a peripheral ID, this command is equivalent to sending Set Peripheral ID (Cmd 66) with a peripheral ID value. However, Set Peripheral ID with data 0 puts controller into safe-mode settings, whereas Restore Settings with data 0 causes the controller to load default values for the assigned peripheral ID.

Set Microstep Resolution - Cmd 37

| Instruction Name | Set Microstep Resolution |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 37 |

| Command Type | Setting |

| Command Data | Microsteps |

| Reply Data | Microsteps |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Changes the number of microsteps per step. |

This command sets the microstep resolution of a device.

This setting is stored in non-volatile memory and will persist after power-down or reset. Use Restore Settings (Cmd 36) to restore all non-volatile settings to factory default.

The default value on most devices is 64. Valid range of microstep resolution is 1 to 256 for version 6.06 and above.

For firmware version 6.01 to 6.05, available microstep resolutions are:

- 1, 2, 4, 8, 16, 32, 64, 128, 256

- 3, 6, 12, 24, 48, 96, 192

- 5, 10, 20, 40, 80, 160

- 9, 18, 36, 72, 144

- 15, 30, 60, 120, 240

- 25, 50, 100, 200

- 27, 54, 108, 216

- 45, 90, 180

All position related settings are in units of microsteps. When you change the microstep resolution, microstep related settings are automatically restored to their default values and then adjusted to match the scale of the new resolution.

If you have previously changed any settings, you will need to reconfigure them after setting a new microstep resolution. The device should be homed after assigning a new microstep resolution.

The following example shows affected settings when resolution is changed from 64 to 32:

| Setting | Default | Before | After |

| Microstep Resolution * | 64 | 64 | 32 |

| Current Position | n/a | 10501 ** | 5250 ** |

| Target Speed * | 153600 | ignored | 76800 |

| Knob Velocity Scale * | 153600 | ignored | 76800 |

| Home Speed * | 50000 | ignored | 25000 |

| Maximum Position * | 280000 | ignored | 140000 |

| Minimum Position * | 0 | ignored | 0 |

| Home Offset * | 0 | ignored | 0 |

| Acceleration * | 205 ** | ignored | 102 ** |

| Deceleration * | 205 ** | ignored | 102 ** |

* The settings for these commands are saved in non-volatile memory.

** Note that if a number is divided by two, it is rounded down to the nearest whole number.

Set Running Current - Cmd 38

| Instruction Name | Set Running Current |

|---|---|

| Applies to | T-LSQ, T-LST, T-MCA, A-series and X-Series motorized devices |

| Firmware Version | 5.00 and up |

| Command Number | 38 |

| Command Type | Setting |

| Command Data | Value |

| Reply Data | Value |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the desired current to be used when the device is moving. |

The specified current limit is applied per motor phase. If your application does not require high torque, it is best to decrease the driving current to reduce power consumption, vibration, and motor heating. If higher torque is required, it is generally safe to overdrive motors as long as they are not operated continuously and do not get too hot; please refer to your product’s specifications for current and temperature limits.

The value of this setting is in 14.1 mA RMS (20 mA peak) increments. As an example, to convert a desired run current of 1.2 A RMS into a data value for this setting:

- data value = 1200 mA RMS ÷ 14.1 mA RMS/data = 85

To determine the actual current given the data value 40:

- current = 40 × 14.1 mA RMS/data = 564 mA RMS

Set Hold Current - Cmd 39

| Instruction Name | Set Hold Current |

|---|---|

| Applies to | T-LSQ, T-LST, T-MCA, A-series and X-Series motorized devices |

| Firmware Version | 5.00 and up |

| Command Number | 39 |

| Command Type | Setting |

| Command Data | Value |

| Reply Data | Value |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the desired current to be used when the device is holding its position. |

It is typical to run stepper motors at their rated current when they are moving (run current) and reduce the current when idle to hold the position (hold current). When a device stops moving, it switches from using the run current to the hold current 0.1 seconds later. This setting specifies the maximum hold current that may be used on each motor phase. If the motor position is between full steps, each phase will use some fraction of the current specified by this setting. Typically the hold current can be set to around 25 - 50% of the running current. In some applications, the friction of the drive system alone is sufficient to hold the microstep position of the motor, and the hold current can be turned off completely. The hold current can be turned off by issuing the "Set Hold Current" instruction with data of 0.

The value of the hold current setting is in 20 mA DC increments. As an example, to convert a desired hold current of 800 mA DC into a data value for this setting:

- data value = 800 mA DC ÷ 20 mA DC/data = 40

To determine the actual current given the data value 40:

- current = 40 × 20 mA DC/data = 800 mA DC

Set Device Mode - Cmd 40

| Instruction Name | Set Device Mode |

|---|---|

| Applies to | A-Series and X-Series motor controllers |

| Firmware Version | 6.xx |

| Command Number | 40 |

| Command Type | Setting |

| Command Data | Mode |

| Reply Data | Mode |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the Device Mode for the given device. |

This command allows setting several options, each controlled by a single bit within the command data. In A-Series and X-Series devices, this command is replaced by individual setting commands. This command is deprecated but is supported for backward compatibility.

To determine what decimal value to use, the command data may be considered as a single 32-bit binary value. The least significant bit is bit_0, the next is bit_1, the next is bit_2, and so on up to the most significant bit_31. Each bit may have a value of either 1 or 0. Any unused or reserved bits should be left as 0.

The corresponding decimal representation of this 32-bit data is given by:

- Decimal value = (bit_0 * 1) + (bit_1 * 2) + … + (bit_n * 2^n) + … + (bit_31 * 2^31)

For example, suppose you want all mode bits to be 0 except for bit_3 (disable knob) and bit_6 (enable message IDs). The Set Device Mode instruction should be sent with data calculated as follows:

- Command Data

- = 2^3 + 2^6

- = 8 + 64

- = 72

Note that each instance of the Set Device Mode command overwrites ALL previous mode bits. Repeated commands do not have a cumulative effect. For example, suppose you send a Set Device Mode command with data of 8 to disable the knob. If you then send another Set Device Mode command with data of 64 to enable message IDs, you will re-enable the knob since bit_3 in the 2nd instruction is 0.

Most devices have a default mode setting of 0 (all bits are 0).

| Bit_n | 2^n | Description

|

| bit_0 | 1 | Disable Auto-reply A value of 1 disables ALL replies except those to “echo”, “read”, “renumber”, and “return” commands. The default value is 0. |

| bit_1 | 2 | Reserved |

| bit_2 | 4 | Reserved |

| bit_3 | 8 | Disable Knob A value of 1 disables knob functionality. All knob turns and depresses are ignored. The default value is 0. |

| bit_4 | 16 | Enable Move Tracking A value of 1 enables the Move Tracking response during move commands. The device will return its position periodically when a move command is executed. The Disable Auto-Reply option above takes precedence over this option. The default value is 0. |

| bit_5 | 32 | Disable Manual Move Tracking A value of 1 disables the Manual Move Tracking response during manual moves. The Disable Auto-Reply option above takes precedence over this option. The default value is 0. |

| bit_6 | 64 | Enable Message IDs A value of 1 enables Message IDs. When message ID is enabled, only bytes 3 through 5 in the command requests and responses are used for data. Byte 6 is used as an ID byte that the user can set to any value they wish. When the device receives a command request with a certain ID byte, it will reply with a command response containing the same ID byte. This allows the user application to monitor communication packets individually to implement error detection and recovery. The default value is 0. |

| bit_7 | 128 | Home Status This value indicates whether a device has been homed and has a valid position reference. This bit is set to 0 automatically on power-up or reset. It is set automatically when the device is homed or when the position is set using command #45. |

| bit_8 | 256 | Disable Auto-Home A value of 1 prevents the home sensor from triggering a homing procedure during a movement command. This allows rotational devices to move multiple revolutions without re-triggering the homing mechanism. |

| bit_9 | 512 | Reverse Knob A value of 1 reverses the direction of the travel when the knob is turned. The default value is 0. |

| bit_10 | 1,024 | Reserved |

| bit_11 | 2,048 | Reserved |

| bit_12 | 4,096 | Set Home Switch Logic A value of 1 indicates that the peripheral is installed with an active high home sensor. Most Zaber peripherals have active low home sensors. For peripherals installed with active high home sensors, this bit must be changed from the default setting in order for the home sensor to function correctly. Damage to the home sensor or actuator may result if this bit is set improperly. See Set Home Sensor Type (Cmd 104) NOTE: This setting in only valid on A-Series and X-Series controllers, setting this bit on other devices will result in an error. |

| bit_13 | 8,192 | Reserved |

| bit_14 | 16,384 | Reserved |

| bit_15 | 32,768 | Reserved |

Set Home Speed - Cmd 41

| Instruction Name | Set Home Speed |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 41 |

| Command Type | Setting |

| Command Data | Speed |

| Reply Data | Speed |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the speed at which the device moves when using the "Home" command. |

When a home instruction is issued, the device will accelerate at a rate determined by the acceleration setting up to the speed determined by this command. The home speed can be set independently of target speed (command 42) so that for stages that move very fast, issuing the home command would use a slower home speed and prevent the stage from crashing into the home position.

For a spreadsheet that can be used to calculate speed setting values for any product see https://www.zaber.com/documents/ZaberSpeedSetting.xls. Alternatively you may use the formulas below.

Actual Speed

- = Data / 1.6384 * M mm/s or deg/s

- = Data / 1.6384 microsteps/s

- = Data / 1.6384 / R steps/s

- = Data / 1.6384 / (R x S) * 60 revolutions/min Motor rpm

- = Data / 1.6384 * L / (R x S) mm/s Linear devices only

where:

- Data is the value of the command data

- R (microsteps/step) is the microstep resolution (command 37)

- S (steps/revolution) is the number of steps per motor revolution

- M (mm or deg) is the microstep size

- L (mm or deg) is the distance of linear motion per motor revolution

Refer to product specifications for the distance corresponding to a single microstep or revolution.

For example, if a motor has 200 steps per revolution (S = 200), used with default resolution (R = 64), and Data is 251658, then the motor will move at a speed of 720 revolutions per minute.

Valid data values are from 1 to (16384×R).

Set Target Speed - Cmd 42

| Instruction Name | Set Target Speed |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 42 |

| Command Type | Setting |

| Command Data | Speed |

| Reply Data | Speed |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the speed at which the device moves when using the "Move Absolute" or "Move Relative" commands. |

When a move absolute or move relative instruction is issued, the device will accelerate at a rate determined by the acceleration setting up to the speed determined by this command.

The target velocity may be changed on-the-fly even when the device is in the middle of a move. The device will automatically adjust the velocity, but still target the final position specified in the original move.

For a spreadsheet that can be used to calculate speed setting values for any product see https://www.zaber.com/documents/ZaberSpeedSetting.xls. Alternatively you may use the formulas below.

Actual Speed

- = Data / 1.6384 * M mm/s or deg/s

- = Data / 1.6384 microsteps/s

- = Data / 1.6384 / R steps/s

- = Data / 1.6384 / (R x S) * 60 revolutions/min Motor rpm

- = Data / 1.6384 * L / (R x S) mm/s Linear devices only

where:

- Data is the value of the command data

- R (microsteps/step) is the microstep resolution (command 37)

- S (steps/revolution) is the number of steps per motor revolution

- M (mm or deg) is the microstep size

- L (mm or deg) is the distance of linear motion per motor revolution

Refer to product specifications for the distance corresponding to a single microstep or revolution.

For example, if a motor has 200 steps per revolution (S = 200), used with default resolution (R = 64), and Data is 251658, then the motor will move at a speed of 720 revolutions per minute.

Valid data values are from 1 to (16384×R).

Set Acceleration - Cmd 43

| Instruction Name | Set Acceleration |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 43 |

| Command Type | Setting |

| Command Data | Acceleration |

| Reply Data | Acceleration |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the acceleration used by the movement commands. |

When a movement command is issued, the device will accelerate and decelerate at a rate determined by this command. The acceleration may be changed on-the-fly even when the device is in the middle of a move.

It is possible to set acceleration and deceleration separately in A-Series and X-Series devices. In which case, use Set Acceleration Only (Cmd 113) and Set Deceleration Only (Cmd 114) instead. When acceleration and deceleration values are different, Return Setting(Data = Set Acceleration) returns the acceleration value only.

To determine the acceleration that will result from a given data value, the following formulas may be used:

- Actual Acceleration

- = 10000 * Data * M / 1.6384 mm/s^2 or deg/s^2

- = 10000 * Data / 1.6384 microsteps/s^2

- = 10000 * Data / R / 1.6384 steps/s^2

Where:

- Data is the value specified in the Command Data

- M (mm or deg) is the microstep size

- R is the microstep resolution set in command #37 (microsteps/step)

The maximum value is 32767.

Set Maximum Position - Cmd 44

| Instruction Name | Set Maximum Position |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 44 |

| Command Type | Setting |

| Command Data | Range |

| Reply Data | Range |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the maximum position the device is allowed to travel to. |

Use this command to limit the range of travel to a value other than the default. Exercise caution when using this command, since it is possible to set the range to a value greater than the physical limits of the device.

A device within range of travel is not allowed to move above its Maximum Position. If the device Current Position is out of range and above Maximum Position, the device is not allowed to move in the positive direction.

The default Maximum Position is the full travel length of the device. Valid values can be any number from -1000000000 to 1000000000.

This setting is stored in non-volatile memory and will persist after power-down or reset.

Set Current Position - Cmd 45

| Instruction Name | Set Current Position |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 45 |

| Command Type | Setting |

| Command Data | New Position |

| Reply Data | New Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | Volatile |

| Summary | Sets the device internal position counter. |

This command override the internal position counter with a new position value specified by the user. The position data is volatile and will not persist after power-down or reset.

Stepper motor phase remains unchanged when position is updated.

Do not use this command to preserve the position counter over power cycles. To restore the position counter without homing the device, Park the stage before power down and Unpark the stage when power is restored. See Set Park State (Cmd 65) for details.

Set Home Offset - Cmd 47

| Instruction Name | Set Home Offset |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 47 |

| Command Type | Setting |

| Command Data | Offset |

| Reply Data | Offset |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets the the new "Home" position which can then be used when the Home command is issued. |

When the home command is issued, the device will retract until the home sensor is triggered, then move forward until the home sensor is no longer triggered, then move forward by the Home Offset value (in microsteps) and resets the internal position (to 0 for most devices).

Note that the home offset command also changes the range settings of the device. For example, if the initial Home Offset is 0 and the Minimum and Maximum Position are 0 and 500,000 respectively, and the user changes the Home Offset to 70,000, then the Minimum and Maximum Position are automatically adjusted to -70,000 and 430,000 respectively. However, changing the Minimum/Maximum Position does not affect the home offset.

When a new Home Offset is specified, Minimum and Maximum Positions are adjusted to provide the same range. The device is able to move in the same travel range as before.

This setting is stored in non-volatile memory and will persist after power-down or reset.

Set Alias Number - Cmd 48

| Instruction Name | Set Alias Number |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 48 |

| Command Type | Setting |

| Command Data | Alias Number |

| Reply Data | Alias Number |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Sets an alternate device number for a device. |

This setting specifies an alternate device number for a device (in addition to its actual device number). By setting several devices to the same alias number, you can control a group of devices with a single instruction. When you send an instruction to an alias number, all devices with that alias number will execute the instruction and reply using their actual device numbers. To remove an alias, simply set the device's alias number to zero. Valid alias numbers are 0 to 99 for version 6.05, and 0 to 254 otherwise. To avoid confusion, it is best to choose an alias greater than the number of devices connected.

This setting is stored in non-volatile memory and will persist after power-down or reset.

Return Device ID - Cmd 50

| Instruction Name | Return Device ID |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 50 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Device ID |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the ID number for the type of device connected. |

See the Zaber support web site for a table of device IDs for all Zaber products.

Return Firmware Version - Cmd 51

| Instruction Name | Return Firmware Version |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 51 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Version |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the firmware version installed on the device. |

A decimal is assumed before the last two digits. For example, 502 indicates firmware version 5.02.

Return Power Supply Voltage - Cmd 52

| Instruction Name | Return Power Supply Voltage |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 52 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Voltage |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the voltage level of the device's power supply. |

A decimal is assumed before the last digit. For example, a value of 127 indicates 12.7 V. Note that the internal voltage measurement is not very accurate. Don't be alarmed if the indicated voltage is slightly different from your measurements.

Return Setting - Cmd 53

| Instruction Name | Return Setting |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.00 and up |

| Command Number | 53 |

| Command Type | Command |

| Command Data | Setting Number |

| Reply Data | Setting Value |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the current value of the setting specified in the Command Data. |

Valid command data values are the command numbers of any "Set..." instruction. The device will reply using the command number of the specified setting (as if a command to change the setting had just been issued) but the setting will not be changed.

For example, command #48 is the "Set Alias" instruction. Therefore if you wish to return the current value of the alias number, simply send the Return Setting instruction with data of 48. The device will reply with command #48 and data equal to the setting value.

Since firmware version 5.21, this command also accepts the command numbers of any "Return..." instruction, such as command #50 "Return Device ID".

Return Status - Cmd 54

| Instruction Name | Return Status |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 54 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Status |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the current status of the device. |

Possible status codes are as follows:

- 0 - idle, not currently executing any instructions

- 1 - executing a home instruction

- 10 - executing a manual move in Velocity Mode (i.e. the manual control knob is turned)

- 11 - executing a manual move in Displacement Mode (i.e. the manual control knob is turned)

- 13 - device has stalled and stopped or been displaced while stationary (FW 6.07 and up only)

- 18 - executing a move to stored position instruction

- 20 - executing a move absolute instruction

- 21 - executing a move relative instruction

- 22 - executing a move at constant speed instruction

- 23 - executing a stop instruction (i.e. decelerating)

- 65 - device is parked (FW 6.02 and up only. FW 6.01 returns 0 when parked)

- 78 - executing a move index instruction

Echo Data - Cmd 55

| Instruction Name | Echo Data |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 5.04 and up |

| Command Number | 55 |

| Command Type | Command |

| Command Data | Data |

| Reply Data | Data |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Echoes back the same Command Data that was sent. |

This command is useful for testing communication, similar to a network "ping".

Return Firmware Build - Cmd 56

| Instruction Name | Return Firmware Build |

|---|---|

| Applies to | All Zaber devices |

| Firmware Version | 6.17 and up |

| Command Number | 56 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Build Number |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the firmware build number installed on the device. |

This is unique to a firmware build even when multiple builds may share the same version, such as custom engineering parts. It is not normally necessary to consult the build number.

Return Current Position - Cmd 60

| Instruction Name | Return Current Position |

|---|---|

| Applies to | All motorized devices |

| Firmware Version | 5.00 and up |

| Command Number | 60 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Position |

| Safe to retry? | Yes |

| Returns Current Position? | Yes |

| Persistence | n/a |

| Summary | Returns the current absolute position of the device in microsteps. |

This is equivalent to issuing a Return Setting (#53) command with a command data value of 45 (Set Current Position).

Return Serial Number - Cmd 63

| Instruction Name | Return Serial Number |

|---|---|

| Applies to | All devices |

| Firmware Version | 5.30 to 5.35, 6.07 and up |

| Command Number | 63 |

| Command Type | Read-Only Setting |

| Command Data | Ignored |

| Reply Data | Serial Number |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | n/a |

| Summary | Returns the serial number of the device. |

Set Park State - Cmd 65

| Instruction Name | Set Park State |

|---|---|

| Applies to | A-Series and X-Series motorized devices |

| Firmware Version | 6.xx |

| Command Number | 65 |

| Command Type | Setting |

| Command Data | Park State |

| Reply Data | Park State |

| Safe to retry? | Yes |

| Returns Current Position? | No |

| Persistence | Non-Volatile |

| Summary | Park or unpark the device. |

This command allows a device to maintain its position reference over a power cycle without requiring homing. This feature is useful when a device needs to be powered down but a Home procedure is not desired at next power up.

- Parking

- To Park the device, issue command 65 with data value of 1. Device will store its internal position settings and shut off all current to the motor. Device can now be powered down.

- Unparking

- To Unpark the device, issue command 65 with data value of 0. Device will resume its previous internal settings and enable current to the motor. Current Position is now set to that when device was parked.