Scope

This manual defines Zaber’s Binary protocol for all products with firmware versions 7.46 and below. Not all commands or settings are supported by all products. See the product-specific protocol manual for which commands and settings a product supports.

This manual defines Zaber’s Binary protocol and the device settings and commands for the GENERIC PRODUCT running firmware version 7.46. Other products or firmware versions may support other commands or settings; see a product’s specific protocol manual for the commands and settings it supports.

If your device uses Firmware 6, refer to the Firmware 6 Binary Protocol Manual. See here for instructions on how to tell which version your device uses.

The Binary protocol has limited features and is supported only on certain products for backwards compatibility. It has been replaced with Zaber’s ASCII protocol, which is actively developed, more robust, and full-featured.

Conventions

Conventions used throughout this document:

- For clarity, each binary message is presented as an array of its fields,

[n, c, d], where:nis the device number,cis the command number, anddis the command-specific data.

- A binary message sent from the host to a device is indicated with a

→suffix (e.g.,[0, 1, 0] →). - A binary message sent from the device to the host is indicated with a

←prefix (e.g.,← [0, 1, 0]).

Physical Units

Many of the setting values and command parameters described in this document relate to physical units, such as distance, voltage, and time. When a setting value is expressed in a real-world metric unit or in a scaled version of a unit, the units are described explicitly (such as a voltage specified in units of volts, or a current specified in 20 mA increments). In other cases, the value is unitless and some scaling factor is required to convert to a practical unit. Unitless values may be referred to in this document as the ‘data’ value.

In general, the documentation of each command or setting describes how to convert the relevant data values to real-world units. An exception is for values involving physical distances or positions (including speed/velocity and acceleration/deceleration), which are described here. This section is referenced whenever they’re used in a command or setting.

Converting data values involving distance or position to real-world values requires a device-specific conversion factor, which is listed in the "Specifications" section of the device’s User Manual.

For stepper motors, this conversion factor is called "Microstep Size". The value in the User Manual assumes the Microstep Resolution is at the default value. If you have modified the resolution value, the Microstep Size can be converted:

The default resolution is available at Zaber Support - Device Settings.

For linear motor or voice coil products, this conversion factor is called "Encoder Count Size".

Position

For stepper motor products, all position and distance data values are in units of stepper motor microsteps. The conversion from distance or position data values to real-world units is given by:

For linear motor or voice coil products, all position and distance data values are in units of encoder counts. The conversion from distance or position data values to real-world units is given by:

Velocity

For stepper motor products, the conversion from velocity or speed data values to real-world units is given by:

For linear motor or voice coil products, the conversion from velocity or speed data values to real-world units is given by:

Acceleration

For stepper motor products, the conversion from acceleration or deceleration data values to real-world units is given by:

For linear motor or voice coil products, the conversion from acceleration or deceleration data values to real-world units is given by:

Quick Start

Connecting

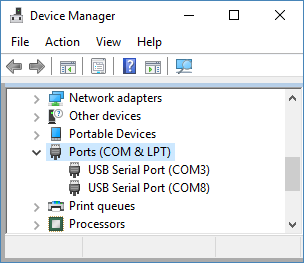

Zaber devices support connecting to user equipment over standard serial connections using Zaber’s Binary protocol. The fastest way to set up Zaber devices with the Binary protocol is to use Zaber Console.

Zaber devices typically communicate over RS-232 at 9600 baud, with 8 bits, 1 stop bit and no parity. However, please refer to the RS-232 Communications section of the device-specific User Manual for supported settings.

Talking to Zaber Devices

Zaber devices listen for commands sent to them over a serial port and respond after completing the command. All binary messages share the same Message Format and encode:

- the device number

- the command number

- the command-specific data

[1, 20, 10000] → // Request to device 1, Move Absolute, Position 10000

← [1, 20, 10000] // Response from device 1, Move Absolute, Position 10000

// (device stopped at final position)To send the same message to all devices in a chain, use device number 0. Each device will send its own response after completing the command:

[0, 20, 10000] → // Request to all devices, Move Absolute, Position 10000

← [1, 20, 10000] // Response from device 1, Move Absolute, Position 10000

← [3, 20, 10000] // Response from device 3, Move Absolute, Position 10000

← [2, 20, 10000] // Response from device 2, Move Absolute, Position 10000Making it Move

After connecting and powering the device, send the Home (Cmd 1) command. The device will move to the home limit sensor and establish a reference position:

[0, 1, 0] → // Request to all devices, Home

← [1, 1, 0] // Response from device 1, Home, Position 0If the device hasn’t been homed, motion commands may not work as expected. The controller’s position limits will not match the physical limits, absolute movements will not move to expected positions, and relative movements the device is capable of may be rejected for being outside the travel range.

Once the device has been homed, make the device move by sending a Move Relative (Cmd 21) command. For example, to move a distance of 10,000 forward from the current position:

// Device 1 at position 555

[0, 21, 10000] → // Request to all devices, Move Relative, Distance 10000

← [1, 21, 10555] // Response from device 1, Move Relative, Position 10555To move to the absolute position 10,000, measured from the home position, regardless of the current position, send a Move Absolute (Cmd 20) command:

// Device 1 at position 555

[0, 20, 10000] → // Request to all devices, Move Absolute, Position 10000

← [1, 20, 10000] // Response from device 1, Move Absolute, Position 10000See the Physical Units section for information about unit conversions.

Using Device Settings

Use the set commands to configure the device. For example, to set the target speed to 10,000:

[0, 42, 10000] → // Request to all devices, Set Target Speed, Speed 10000

← [1, 42, 10000] // Response from device 1, Set Target Speed, Speed 10000The target speed is now set to 10,000.

To read the value of a setting use the Return Setting (Cmd 53) command:

[0, 53, 42] → // Request to all devices, Return Setting, Set Target Speed

← [1, 42, 10000] // Response from device 1, Set Target Speed, Speed 10000The current target speed is 10,000.

Read-only settings (as well as a few writable settings) have a return command for reading their value. For example, to read the device status:

[0, 54, 0] → // Request to all devices, Return Status

← [1, 54, 99] // Response from device 1, Return Status, Device busyFor convenience, return commands can also be passed as data to Return Setting (Cmd 53):

[0, 53, 54] → // Request to all devices, Return Setting, Return Status

← [1, 54, 99] // Response from device 1, Return Status, Device busyMessage Format

All Binary messages consist of six bytes. They must be transmitted with less than 10 milliseconds between each byte. If the device has received less than six bytes and a period longer than 10 milliseconds passes, it will assume the remaining data has been lost and will discard the previously received bytes. We recommend that customer software behave similarly when receiving data from devices, especially in electrically noisy environments.

The six bytes are ordered as follows:

- Device number

- Command number

- Data, least significant byte (LSB)

- Data

- Data

- Data, most significant byte (MSB)

The first byte is the device number in the daisy-chain. Generally, device number 1 is the closest device to the computer, device 2 is next, and so on (see Renumber (Cmd 2) to sequentially number devices in the chain). If the number 0 is used, the command will be directed to all devices in the chain. Each axis of a multi-axis device appears as a separate device with its own device number.

The second byte is the command number. Bytes 3, 4, 5, and 6 can be combined to form a signed 32-bit data value, with the least significant byte transmitted first (see Appendix B: Message Data Conversion Algorithm for more details). Each command interprets the data value differently.

There are four types of commands:

- Action commands

-

Commands that cause the device to perform an action (e.g., move). See Action Command Reference for a list of all action commands.

- Set commands

-

Commands that set the value of a setting. See Set Command Reference for a list of all set commands.

- Return commands

-

Commands that return a setting’s value. See Return Command Reference for a list of all return commands.

- Reply-Only commands

-

Messages that are only ever sent from the device to the user. Most are spontaneously sent by the device and are not in response to a user command. See Reply-Only Command Reference for a list of all reply-only commands.

Most commands elicit a reply message in the same six-byte format, with a few minor differences. The first byte in the reply is the number of the device that just finished executing the command, not the device number the original message was sent to. For instance, a message addressed to 0 (i.e., all devices) will elicit a reply from each device in the daisy-chain. The second byte is either the number of the command that the device just executed or 255 (0xFF) if an error occurs (see Error (Cmd 255) for more information on errors).

If desired, byte 6 can be repurposed as a message ID (in place of a byte of data). See Message ID Mode for more information.

Example: How to encode binary commands

Various commands and their byte encoding according to the Binary message format are shown below.

| Command Description | Device | Command | Data (LSB → MSB) | |||

|---|---|---|---|---|---|---|

| Request to all devices, Home (Cmd 1) | 0 | 1 | 0 | 0 | 0 | 0 |

| Request to all devices, Renumber (Cmd 2) | 0 | 2 | 0 | 0 | 0 | 0 |

| Request to all devices, Return Firmware Version (Cmd 51) | 0 | 51 | 0 | 0 | 0 | 0 |

| Request to device 1, Move Absolute (Cmd 20) to position 257 | 1 | 20 | 1 | 1 | 0 | 0 |

| Request to device 2, Move Relative (Cmd 21) a distance of -1 | 2 | 21 | 255 | 255 | 255 | 255 |

Quick Command Reference

| Name | Command | Data | Type | Reply Data |

|---|---|---|---|---|

| Reset | 0 | Ignored | Action | None |

| Home | 1 | Ignored | Action | Current position |

| Renumber | 2 | Device number | Action | Device ID |

| Move Tracking | 8 | Ignored | Reply-only | Current position |

| Limit Active | 9 | Ignored | Reply-only | Current position |

| Manual Move Tracking | 10 | Ignored | Reply-only | Current position |

| Manual Move | 11 | Ignored | Reply-only | Current position |

| Slip Tracking | 12 | Ignored | Reply-only | Encoder position |

| Unexpected Position | 13 | Ignored | Reply-only | Encoder position |

| Store Current Position | 16 | Number | Action | Number |

| Return Stored Position | 17 | Number | Action | Stored position |

| Move To Stored Position | 18 | Number | Action | Current position |

| Move Absolute | 20 | Absolute position | Action | Current position |

| Move Relative | 21 | Distance | Action | Current position |

| Move at Constant Speed | 22 | Velocity | Action | Velocity |

| Stop | 23 | Ignored | Action | Current position |

| Restore Settings | 36 | 0 or peripheral ID | Action | 0 or peripheral ID |

| Set Microstep Resolution | 37 | Number of microsteps | Set | Number of microsteps |

| Set Run Current | 38 | Run current | Set | Run current |

| Set Hold Current | 39 | Hold current | Set | Hold current |

| Set Home Speed | 41 | Speed | Set | Speed |

| Set Target Speed | 42 | Speed | Set | Speed |

| Set Acceleration | 43 | Acceleration | Set | Acceleration |

| Set Maximum Position | 44 | Position | Set | Position |

| Set Current Position | 45 | Position | Set | Position |

| Set Home Offset | 47 | Offset | Set | Offset |

| Set Alias Number | 48 | Alias number | Set | Alias number |

| Return Device ID | 50 | Ignored | Return | Device ID |

| Return Firmware Version | 51 | Ignored | Return | Version |

| Return Power Supply Voltage | 52 | Ignored | Return | Voltage |

| Return Setting | 53 | Setting to return | Action | Setting value |

| Return Status | 54 | Ignored | Return | Status |

| Echo Data | 55 | Data | Action | Data |

| Return Firmware Build | 56 | Ignored | Return | Build number |

| Return Current Position | 60 | Ignored | Return | Position |

| Return Serial Number | 63 | Ignored | Return | Serial number |

| Set Park State | 65 | Park state | Set | Park state |

| Set Peripheral ID | 66 | Peripheral ID | Set | Peripheral ID |

| Return Digital Input Count | 67 | Ignored | Return | Digital input channel count |

| Read Digital Input | 68 | Channel number | Action | Channel state |

| Read All Digital Inputs | 69 | Ignored | Action | Channel states |

| Return Digital Output Count | 70 | Ignored | Return | Digital output channel count |

| Read Digital Output | 71 | Channel number | Action | Channel state |

| Read All Digital Outputs | 72 | Ignored | Action | Channel states |

| Write Digital Output | 73 | Channel state | Action | Channel state |

| Write All Digital Outputs | 74 | Channel states | Action | Channel states |

| Return Analog Input Count | 75 | Ignored | Return | Analog input channel count |

| Read Analog Input | 76 | Channel number | Action | Channel voltage |

| Move Index | 78 | Index number, which must be positive | Action | Current position |

| Set Index Distance | 79 | Distance | Set | Distance |

| Set Cycle Distance | 80 | Distance | Set | Distance |

| Set Filter Holder ID | 81 | Holder ID | Set | Filter holder ID |

| Return Encoder Count | 82 | Ignored | Return | Encoder count |

| Return Calibrated Encoder Count | 83 | Ignored | Return | Calibrated encoder count |

| Return Calibration Type | 84 | Ignored | Return | Calibration type |

| Return Calibration Error | 85 | Ignored | Return | Calibration error |

| Return Peripheral Serial Number | 86 | Ignored | Return | Peripheral serial number |

| Return Encoder Position | 89 | Ignored | Return | Encoder position in distance units |

| Return Pending Peripheral ID | 91 | Ignored | Return | Peripheral ID |

| Return Pending Peripheral Serial Number | 92 | Ignored | Return | Peripheral serial number |

| Activate | 93 | Ignored | Action | None |

| Set Auto-Reply Disabled Mode | 101 | Auto-reply disabled mode | Set | Auto-reply disabled mode |

| Set Message ID Mode | 102 | Message ID mode | Set | Message ID mode |

| Set Home Status | 103 | Home status | Set | Home status |

| Set Auto-Home Disabled Mode | 105 | Auto-home disabled mode | Set | Auto-home disabled mode |

| Set Minimum Position | 106 | Position | Set | Position |

| Set Knob Disabled Mode | 107 | Knob disabled mode | Set | Knob disabled mode |

| Set Knob Direction | 108 | Knob direction | Set | Knob direction |

| Set Knob Movement Mode | 109 | Knob movement mode | Set | Knob movement mode |

| Set Knob Jog Size | 110 | Distance | Set | Distance |

| Set Knob Velocity Scale | 111 | Speed | Set | Speed |

| Set Knob Velocity Profile | 112 | Interpolation | Set | Interpolation |

| Set Acceleration Only | 113 | Acceleration | Set | Acceleration |

| Set Deceleration Only | 114 | Deceleration | Set | Deceleration |

| Set Move Tracking Mode | 115 | Move tracking mode | Set | Move tracking mode |

| Set Manual Move Tracking Disabled Mode | 116 | Manual move tracking disabled mode | Set | Manual move tracking disabled mode |

| Set Move Tracking Period | 117 | Move tracking period (ms) | Set | Move tracking period (ms) |

| Set Closed-Loop Mode | 118 | Closed-loop mode | Set | Closed-loop mode |

| Set Slip Tracking Period | 119 | Slip tracking period (ms) | Set | Slip tracking period (ms) |

| Set Stall Timeout | 120 | Stall timeout | Set | Stall timeout |

| Set Baud Rate | 122 | Baud rate | Set | Baud rate |

| Set Protocol | 123 | Protocol | Set | Protocol |

| Convert to ASCII | 124 | Baud rate | Action | Baud rate |

| Error | 255 | Ignored | Reply-only | Error code |

Action Command Reference

The following section details Binary action commands. Use these commands to perform an action or task (e.g., move the device, restore settings, etc.).

Reset (Cmd 0)

Resets the device to the power-up state

- Data

- Ignored

- Reply Data

- None

This command resets the device to the power-up state. After receiving this command, the device waits until no other chained devices have communicated for 200 ms before performing the reset. Any commands sent to the device during this 200 ms period are discarded with no reply sent. The device does not reply to this command.

Example: Resetting the device

[1, 0, 0] → // Request to device 1, Reset

// No response from device 1Home (Cmd 1)

Moves the device to the home position

- Data

- Ignored

- Reply Data

- Current position

Moves the device towards the home position at the Home Speed until the home sensor is triggered. Once the home position is reached, the current position is reset (to 0 for most devices), establishing the reference position. If a Home Offset has been specified, the device will move forward the specified offset before resetting the position.

Error Codes

This command may return the following error codes:

- 1

-

Cannot Home

The device has travelled a long distance without triggering the home sensor. It may be stalling or slipping.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Renumber (Cmd 2)

Updates the device number of one or more devices

- Data

-

Device number

1 to 254

- Reply Data

Device ID

When this command is sent to all devices in a daisy-chain, it sequentially sets the device number of each device. The device closest to the computer is given device number 1. The remaining devices in the daisy-chain are numbered consecutively.

When Renumber (Cmd 2) is sent to a specific device number, it sets the device number to the specified value on that device only.

Error Codes

This command may return the following error codes:

- 2

-

Device Number Invalid

The requested device number is out of range.

See also Error (Cmd 255)

Example: Renumbering all devices in a chain

[0, 2, 0] → // Request to all devices, Renumber, Device number 0

← [1, 2, 50000] // Response from device 1, Renumber, Device ID 50000

← [2, 2, 30211] // Response from device 2, Renumber, Device ID 30211The devices are renumbered, with the device closest to the computer having device number 1, and the next closest having device number 2.

Example: Renumbering a specific device

Renumber device 2 to 4:

[2, 2, 4] → // Request to device 2, Renumber, Device number 4

← [4, 2, 50000] // Response from device 4, Renumber, Device ID 50000Store Current Position (Cmd 16)

Stores the current position

- Data

-

Number

0 to 15

- Reply Data

- Number

Saves the current position into the stored position specified by <number>. A total of 16 positions (numbered 0 to 15) can be stored. Stored positions are non-volatile and persist after a power-up or system reset. This command can only be executed after the device has been homed.

See also Move To Stored Position (Cmd 18) and Return Stored Position (Cmd 17).

Error Codes

This command may return the following error codes:

- 1600

-

Save Position Invalid

The requested stored position index is out of range.

- 1601

-

Save Position Not Homed

Store Current Position is not allowed until the device has been homed.

See also Error (Cmd 255)

Return Stored Position (Cmd 17)

Returns a stored position

- Data

-

Number

0 to 15

- Reply Data

- Stored position

Returns a position previously stored by a Store Current Position (Cmd 16) command. The data specifies which stored position to return.

See also Move To Stored Position (Cmd 18).

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 1700

-

Return Position Invalid

The requested stored position index is out of range.

See also Error (Cmd 255)

Move To Stored Position (Cmd 18)

Moves to a stored position

- Data

-

Number

0 to 15

- Reply Data

- Current position

Moves the axis to the stored position specified by the number in the data value. Each stored position defaults to position 0 until another position is saved to it, so moving to a stored position that has not been set will move the axis to position 0. This command can only be executed after the device has been homed.

To store a position, use Store Current Position (Cmd 16). To read the value of a stored position, use Return Stored Position (Cmd 17).

Error Codes

This command may return the following error codes:

- 18

-

Stored Position Invalid

The position stored in the requested register is no longer valid. This is probably because the maximum range was reduced.

- 1800

-

Move Position Invalid

The requested stored position is out of range.

- 1801

-

Move Position Not Homed

Move to Stored Position is not allowed until the device has been homed.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Move Absolute (Cmd 20)

Moves the device to an absolute position

- Data

-

Absolute position

Must be in the range Minimum Position to Maximum Position

- Reply Data

- Current position

Moves the device to the specified absolute position.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 20

-

Absolute Position Invalid

The requested target position is out of range.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Move Relative (Cmd 21)

Moves the device a specified distance

- Data

-

Distance

Must be in the range Minimum Position - Current Position to Maximum Position - Current Position

- Reply Data

- Current position

Moves the device the specified distance away from the current position. The distance may be positive or negative.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 21

-

Relative Position Invalid

The requested target position is out of range.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Move at Constant Speed (Cmd 22)

Moves the device at a constant velocity

- Data

-

Velocity

Must be in the range −Microstep Resolution × 16,384 to Microstep Resolution × 16,384

- Reply Data

- Velocity

Moves the device at a constant velocity until Minimum Position or Maximum Position is reached, a limit sensor is triggered, or the motion is preempted by another movement command such as Stop (Cmd 23).

Unlike other binary motion commands, this command replies immediately rather than waiting until the motion completes. When the motion completes normally, the device sends Limit Active (Cmd 9).

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 22

-

Velocity Invalid

The requested velocity is out of range.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Stop (Cmd 23)

Decelerates the device and brings it to a halt

- Data

- Ignored

- Reply Data

- Current position

Decelerates the device to a halt. The device decelerates at the rate defined by Deceleration Only unless the device is already stopping; if the device is already stopping, the device attempts to stop instantly.

Pressing the manual control knob produces the same effect as this command.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Restore Settings (Cmd 36)

Restores device settings to their factory values

- Data

-

0 or peripheral ID

On products with integrated controllers, data must be 0.

- Reply Data

-

0 or peripheral ID

On products with integrated controllers, 0 is always returned.

Restores device settings to their factory values. Communication settings are not modified.

On a controller, if the data value is 0, the default setting values for the current peripheral ID are restored. If the data is any valid Peripheral ID (except 0), then the default setting values for the new peripheral ID are loaded.

On multi-axis products, sending this command to any axis will restore settings on all axes. If a peripheral ID is provided, it will only be loaded on the axis to which the command is addressed. On all other axes, the default settings for the existing peripheral ID will be loaded.

Error Codes

This command may return the following error codes:

- 36

-

Restore Settings Data Invalid

The requested peripheral ID is invalid or not supported by the controller. Data must be 0 on products with integrated controllers.

See also Error (Cmd 255)

Return Setting (Cmd 53)

Returns the current value of a setting

- Data

- Setting to return

- Reply Data

- Setting value

Valid command data values are the command numbers of any set or return command. The device will reply using the command number of the specified setting (as if a command to change the setting had just been issued) but the setting will not be changed.

Error Codes

This command may return the following error codes:

- 53

-

Setting Invalid

The requested setting command number is invalid in this firmware version or on this device.

See also Error (Cmd 255)

Example: Reading the minimum position

Get the Minimum Position.

[1, 53, 106] → // Request to device 1, Return Setting, Set Minimum Position

← [1, 106, 2000] // Response from device 1, Set Minimum Position, Position 2000Example: Reading the current position

Get the Current Position. This returns the same value as Return Current Position (Cmd 60).

[1, 53, 60] → // Request to device 1, Return Setting, Return Current Position

← [1, 60, 5500] // Response from device 1, Return Current Position, Position 5500Echo Data (Cmd 55)

Echoes the provided message data back to the user

- Data

- Data

- Reply Data

- Data

This command is useful for testing communication, similar to a network "ping".

Example: Echoing back message data

[1, 55, 5555] → // Request to device 1, Echo Data, 5555

← [1, 55, 5555] // Response from device 1, Echo Data, 5555Read Digital Input (Cmd 68)

Returns the state of a digital input channel

- Data

- Channel number

- Reply Data

- Channel state

Returns the state of a digital input channel. This command returns 0 for off or 1 for on.

Introduced in 7.09

Error Codes

This command may return the following error codes:

- 68

-

Digital Input Pin Invalid

The requested digital input pin does not exist.

See also Error (Cmd 255)

Read All Digital Inputs (Cmd 69)

Returns the states of all digital input channels

- Data

- Ignored

- Reply Data

- Channel states

The reply data is a binary encoding of the states of all digital input channels. The least significant bit of the reply data corresponds to digital input channel 1, the next bit corresponds to digital input channel 2, and so on. The bit will be 0 if the corresponding digital input channel is off, and 1 if the channel is on.

Any bits beyond the number of channels available on the device always read as 0. Use the Return Digital Input Count setting to determine the number of digital input channels available on the device.

Introduced in 7.09

Example: Reading all digital inputs

[1, 69, 0] → // Request to device 1, Read All Digital Inputs

← [1, 69, 5] // Response from device 1, Read All Digital Inputs, Channel states 5The returned data value 5 encodes the data for all digital inputs. First, convert 5 to its bitwise representation: 1 in the least significant bit, 0 in the next bit, and 1 in the next bit. This tells us that digital input channel 1 is on, digital input channel 2 is off, and digital input channel 3 is on. All other digital input channels, if they exist, are off.

Read Digital Output (Cmd 71)

Returns the state of a digital output channel

- Data

- Channel number

- Reply Data

- Channel state

Returns the state the device is currently driving the specified digital output channel at. This command returns 0 for off or 1 for on.

Introduced in 7.09

Error Codes

This command may return the following error codes:

- 71

-

Digital Output Pin Invalid

The requested digital output pin does not exist.

See also Error (Cmd 255)

Read All Digital Outputs (Cmd 72)

Returns the states of all digital output channels

- Data

- Ignored

- Reply Data

- Channel states

The reply data is a binary encoding of the states the device is currently driving all digital output channels at. The least significant bit of the reply data corresponds to digital output channel 1, the next bit corresponds to digital output channel 2, and so on. The bit will be 0 if the corresponding digital output channel is off, and 1 if the channel is on.

Any bits beyond the number of channels available on the device always read as 0. Use the Return Digital Output Count setting to determine the number of digital output channels available on the device.

Introduced in 7.09

Example: Reading all digital outputs

[1, 72, 0] → // Request to device 1, Read All Digital Outputs

← [1, 72, 2] // Response from device 1, Read All Digital Outputs, Channel states 2The returned data value 2 encodes the data for all digital outputs. First, convert 2 to its bitwise representation: 0 in the least significant bit, 1 in the next bit, and 0 in all remaining bits. This tells us that digital output channel 1 is off, digital output channel 2 is on, and all other digital output channels are off (if they exist).

Write Digital Output (Cmd 73)

Sets the state of a digital output channel

- Data

- Channel state

- Reply Data

- Channel state

Sets the state of a digital output channel. The command data must be 2 × C + V, where C is the channel number to set and V is the value to set (either 0 for off or 1 for on).

Introduced in 7.09

Example: Setting a digital output

Turn on digital output channel 1. The channel number, C, is 1. The value, V, is on, or 1. Therefore the command data should be 2 x C + V = 2 x (1) + (1) = 3.

[1, 73, 3] → // Request to device 1, Write Digital Output, Channel state 3

← [1, 73, 3] // Response from device 1, Write Digital Output, Channel state 3Error Codes

This command may return the following error codes:

- 71

-

Digital Output Pin Invalid

The requested digital output pin does not exist.

See also Error (Cmd 255)

Write All Digital Outputs (Cmd 74)

Writes the states of all digital outputs

- Data

- Channel states

- Reply Data

- Channel states

The command data is a binary encoding of the states to set on all digital output channels. The least significant bit of the command data is sent to digital output channel 1, the next bit is sent to digital output channel 2, and so on.

Any bits beyond the number of channels available on the device always read as 0. Use the Return Digital Output Count setting to determine the number of digital output channels available on the device.

Introduced in 7.09

Example: Setting all digital outputs

Suppose the device has two digital outputs and we want to turn digital output channel 1 off (0) and channel 2 on (1). Then, the command data should have the value for channel 1 in the least significant bit, and the value for channel 2 in the next bit. All other bits should be set to 0. Convert to the decimal representation by adding the powers of two: 0 x 20 + 1 x 21 = 2.

[1, 74, 2] → // Request to device 1, Write All Digital Outputs, Channel states 2

← [1, 74, 2] // Response from device 1, Write All Digital Outputs, Channel states 2Error Codes

This command may return the following error codes:

- 74

-

Digital Output Mask Invalid

The requested mask sets one or more nonexistent digital output pins to 1.

See also Error (Cmd 255)

Read Analog Input (Cmd 76)

Returns the voltage of an analog input channel

- Data

- Channel number

- Reply Data

- Channel voltage

Returns the value of an analog input channel. This command returns voltage measured in hundreds of microvolts. Use the Return Analog Input Count setting to determine the number of analog input channels available on the device.

Introduced in 7.11

Error Codes

This command may return the following error codes:

- 76

-

Analog Input Pin Invalid

The requested analog input pin does not exist.

See also Error (Cmd 255)

Example: Reading an analog input channel

[1, 76, 1] → // Request to device 1, Read Analog Input, Channel number 1

← [1, 76, 4770] // Response from device 1, Read Analog Input, Channel voltage 4770The returned data value is in hundreds of microvolts, so the actual voltage is 4770 x 100 µV / 100,000 = 4.77 V.

Move Index (Cmd 78)

Moves the device to an index position

- Data

Index number, which must be positive

- Reply Data

- Current position

Moves the device to the specified index position. Index positions are positions separated by Index Distance. For a provided index number i, the device moves to the absolute position (i - 1) × Index Distance.

For devices with a non-zero Cycle Distance, the target position must be greater or equal to 0 and less than Cycle Distance. The device moves either clockwise or counter-clockwise, depending on which direction yields the shortest distance to the target position. For rotary devices, to equally space all index positions within a rotation, set Index Distance to a factor of Cycle Distance. If Cycle Distance is 0, the target position must be within the valid travel of the device, i.e., in the range Minimum Position to Maximum Position.

For linear devices, the target position must be within the valid travel of the device, i.e., in the range Minimum Position, Maximum Position.

Error Codes

This command may return the following error codes:

- 78

-

Move Index Number Invalid

The requested target index is invalid.

- 6501

-

Device Parked

The device is currently parked. Use Park State or Home (Cmd 1) to unpark the device before requesting a move.

- 9001

-

Driver Disabled

The device has disabled the driver due to an overheating or over-current condition, or because the driver voltage is outside the normal operating range. The device cannot move. To re-enable the driver, send the Reset (Cmd 0) command.

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Activate (Cmd 93)

Activates the peripheral

- Data

- Ignored

- Reply Data

- None

This command will activate the peripheral. It should be used in cases in which the controller does not automatically activate the peripheral. See Appendix C: Configuring and Activating Peripherals for more detailed information about configuring and activating peripherals.

If the peripheral is already activated (i.e., Status does not return 93), this command will be accepted but will have no side effects.

On an autodetect peripheral, this command will be accepted if a supported autodetect peripheral is plugged in. If the axis is not already configured for the plugged in peripheral (i.e., if Peripheral ID does not match Pending Peripheral ID), it will update Peripheral ID to the value stored on the peripheral.

On a peripheral without the autodetect feature, this command will be rejected if the firmware can detect that the configured peripheral is not present.

For some peripheral and controller combinations, the controller will not be able to tell that the peripheral is unplugged until it activates the peripheral and tries to drive current. On these products, the controller will accept the Activate command when the peripheral is unplugged, but will deactivate shortly after.

This command will fail if the product’s peripheral ID is not supported by the firmware version or by the controller. If this occurs, use Zaber Launcher to upgrade to the most recent firmware version before retrying.

Introduced in 7.11

Error Codes

This command may return the following error codes:

- 9301

-

Peripheral Inactive

The axis is inactive. See Appendix C: Configuring and Activating Peripherals for more information about activating peripherals.

See also Error (Cmd 255)

Convert to ASCII (Cmd 124)

Switches the communications protocol to ASCII and sets the RS-232 baud rate at the same time

- Data

-

Baud rate

9600, 19200, 38400, 57600, 115200

- Reply Data

- Baud rate

This command switches the Protocol to the ASCII protocol and configures the Baud Rate at the same time. After receiving this command and replying, the device waits until no other chained devices have communicated for 200 ms before changing the protocol and baud rate. Any commands sent to the device during this period are discarded with no reply sent.

These changes will persist after power-up or reset.

Communication always uses 8 bits, 1 stop bit, no parity and no flow control.

Error Codes

This command may return the following error codes:

- 124

-

Baud Rate or Protocol Invalid

The requested baud rate is not supported in the ASCII protocol.

See also Error (Cmd 255)

Example: Switch from Binary to ASCII

[1, 124, 115200] → // Request to device 1, Convert to ASCII, Baud rate 115200

← [1, 124, 115200] // Response from device 1, Convert to ASCII, Baud rate 115200Set Command Reference

The following section details Binary set commands. Use these commands to set the value of a specific setting.

Set Microstep Resolution (Cmd 37)

Sets the number of microsteps per motor step

- Data

-

Number of microsteps

1 to 256

- Reply Data

Number of microsteps

- Persistence

- Non-volatile

Set the number of microsteps per step of the stepper motor. A typical Zaber X-series motorized axis uses a stepper motor with 200 steps per motor revolution and a default microstep resolution of 64, therefore it takes 12,800 (200 × 64) microsteps to make one full revolution of the motor. To look up these parameters for a specific device, see the "Motor Steps Per Rev" and the "Default Resolution" entries in the product’s User Manual.

See the Physical Units section for information about unit conversions.

Stored Positions are not updated when microstep resolution is changed.

Error Codes

This command may return the following error codes:

- 37

-

Resolution Invalid

The requested microstep resolution is invalid.

See also Error (Cmd 255)

Set Run Current (Cmd 38)

Sets the current used when the device is moving

- Data

-

Run current

0 to 214,748 (device’s maximum will be lower)

- Reply Data

Run current

- Persistence

- Non-volatile

Sets the current, in 20.0 mA peak (14.1 mA RMS) increments, applied to each motor phase when moving. The default Run Current value for a device is based on the current rating of the motor, as well as as the temperature the device reaches during continuous operation (see the "Specifications" section of the device’s User Manual for the motor’s rated current). The Run Current value can be reduced to lower the temperature and power consumption of the device, but it will also lower the torque the motor can generate. It can be raised to increase the motor’s torque, but this may also raise the temperature. Please contact Zaber Support if you have questions or concerns about raising Run Current.

See Hold Current for information on the current when the driver is not moving the device.

Error Codes

This command may return the following error codes:

- 38

-

Run Current Invalid

The requested run current is out of range.

See also Error (Cmd 255)

Example: Setting the run current

To set the run current to 1.2 A RMS, the data value should be 1200 mA RMS / 14.1 mA RMS = 85.

[0, 38, 85] → // Request to all devices, Set Run Current, Run Current 85

← [1, 38, 85] // Response from device 1, Set Run Current, Run Current 85Set Hold Current (Cmd 39)

Sets the current used when holding the position of the device

- Data

-

Hold current

0 to 214,748

- Reply Data

Hold current

- Persistence

- Non-volatile

Sets the current, in 20.0 mA increments, that the driver may apply to each motor phase to maintain the motor’s position. It is typical to drive a motor at its rated current when it is moving (Run Current), and to reduce the current when idle to hold the position. When the driver stops moving the axis, it waits 100 ms, then switches from applying run current to hold current. The default hold current is typically 25 % - 50 % of the run current.

For certain applications of stepper motors, the friction of the drive system may be sufficient to hold the position of the motor, and Hold Current can be set to 0.

Error Codes

This command may return the following error codes:

- 39

-

Hold Current Invalid

The requested hold current is out of range.

See also Error (Cmd 255)

Example: Setting the hold current

To set the hold current to 800 mA, the value should be 800 mA / 20 mA = 40.

[0, 39, 40] → // Request to all devices, Set Hold Current, Hold Current 40

← [1, 39, 40] // Response from device 1, Set Hold Current, Hold Current 40Set Home Speed (Cmd 41)

Sets the speed at which the device homes

- Data

-

Speed

1 to Microstep Resolution × 16,384

- Reply Data

Speed

- Persistence

- Non-volatile

When the device has not been homed (i.e., Home Status is 0), or during a Home (Cmd 1) command, the device travels at the lesser of Home Speed and Target Speed. To safely control fast-moving devices during homing, set the home speed lower than Target Speed.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 41

-

Home Speed Invalid

The requested home speed is out of range.

See also Error (Cmd 255)

Set Target Speed (Cmd 42)

Sets the maximum speed at which the device moves

- Data

-

Speed

1 to Microstep Resolution × 16,384

- Reply Data

Speed

- Persistence

- Non-volatile

When a movement command is issued, the device accelerates up to and travels at this speed. If a movement command explicitly specifies a speed for the motion (for instance, Move at Constant Speed (Cmd 22)), Target Speed is ignored, and the device travels at the speed specified in the command. During a Home (Cmd 1) command, as well as anytime there is no reference position, the device travels at the lesser of Home Speed and Target Speed.

If the target speed is changed while the device is moving, the device will immediately apply the new speed and continue to move to the target position.

See the Physical Units section for information about unit conversions.Error Codes

This command may return the following error codes:

- 42

-

Speed Invalid

The requested target speed is out of range.

See also Error (Cmd 255)

Set Acceleration (Cmd 43)

Sets the acceleration and deceleration used when changing speeds

- Data

-

Acceleration

0 to 2,147,483,647

- Reply Data

Acceleration

- Persistence

- Non-volatile

Sets the acceleration and deceleration used for motion commands.

If the acceleration is changed while the device is moving, the device will immediately apply the new acceleration and continue to move to the target position.

To set acceleration and deceleration separately use Set Acceleration Only (Cmd 113) and Set Deceleration Only (Cmd 114). When acceleration and deceleration are different, Return Setting (Cmd 53) for this command returns the acceleration value only.

See the Physical Units section for information about unit conversions.Error Codes

This command may return the following error codes:

- 43

-

Acceleration Invalid

The requested target acceleration is out of range.

See also Error (Cmd 255)

Set Maximum Position (Cmd 44)

Sets the maximum position the device can move to

- Data

-

Position

-1,000,000,000 to 1,000,000,000

- Reply Data

Position

- Persistence

- Non-volatile

Sets the maximum position the device can move to. The range of travel (Minimum Position to Maximum Position) is different for each product.

Error Codes

This command may return the following error codes:

- 44

-

Maximum Position Invalid

The requested maximum position is out of range.

See also Error (Cmd 255)

Set Current Position (Cmd 45)

Sets the absolute position of the device

- Data

-

Position

-1,000,000,000 to 1,000,000,000

- Reply Data

Position

- Persistence

- Volatile

The Current Position setting is an absolute measure (with reference to the limits) of the position at which the device should be.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 45

-

Current Position Invalid

The requested position is out of range.

See also Error (Cmd 255)

Set Home Offset (Cmd 47)

Sets an offset from the default home position

- Data

-

Offset

- Reply Data

-

Offset

- Persistence

- Non-volatile

This command shifts the frame of reference so that Current Position is at the default position after homing (0 on most devices) at a distance of Home Offset from the home position. To maintain the same physical travel range, setting Home Offset also updates Minimum Position, Maximum Position, and Current Position. When homing, the device moves toward the home sensor until it is triggered. Once the home position is reached, it moves forward by the Home Offset value before resetting the current position to the default post-homing value.

The command will be rejected if the offset places the home position beyond the physical limits of the device (i.e., if the value is less than Minimum Position or greater than Maximum Position). It will also be rejected if the resulting value of any of Minimum Position, Maximum Position, or Current Position is outside the valid range for that setting.

Error Codes

This command may return the following error codes:

- 47

-

Offset Invalid

The requested home offset is out of range or would produce invalid device bounds.

See also Error (Cmd 255)

Example: Configuring the device to home to an offset position

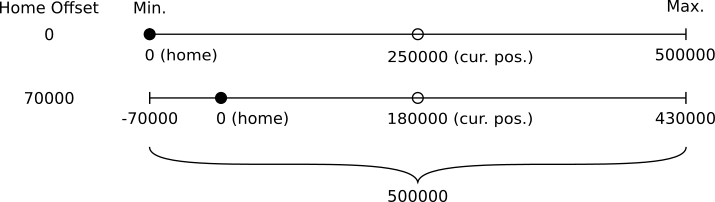

If the device’s initial Home Offset, Minimum Position, Current Position, and Maximum Position are 0, 0, 250000, and 500000, respectively, then setting Home Offset to 70000 will shift Minimum Position to -70000 (0 - 70000), Current Position to 180000 (250000 - 70000), and Maximum Position to 430000 (500000 - 70000) to maintain the same physical travel range.

Example: Attempting to offset the home position beyond the maximum position

If the device’s initial Home Offset, Minimum Position, and Maximum Position are 0, 0, and 500000, respectively, then setting Home Offset to 500001 would place the offset home position beyond the Maximum Position and will return an error.

[0, 53, 44] → // Request to all devices, Return Setting, Set Maximum Position

← [1, 44, 500000] // Response from device 1, Set Maximum Position, Position 500000

[0, 47, 500001] → // Request to all devices, Set Home Offset, Position 500001

← [1, 255, 47] // Response from device 1, Error, Offset InvalidSet Alias Number (Cmd 48)

Sets an alternative device number

- Data

-

Alias number

0 to 254

- Reply Data

Alias number

- Persistence

Non-volatile

An alias is an alternative number for a device, in addition to its actual device number. The device will respond to commands addressed to either its alias or device number. The device will reply using its device number, not its alias number. To remove an alias, set Alias Number to 0.

By setting several devices to the same alias number, groups of devices can be controlled with a single command. To avoid confusion, it is best to choose an alias number greater than the number of connected devices.

Error Codes

This command may return the following error codes:

- 48

-

Alias Invalid

The requested alias is out of range.

See also Error (Cmd 255)

Set Park State (Cmd 65)

Parks or unparks a device

- Data

-

Park state

- 0

Unpark

- 1

Park

- Reply Data

-

Park state

- Persistence

- Non-volatile

Parking allows the device to be turned off and then used at a later time without first having to Home (Cmd 1) the device. To park a device, set Park State to 1. A parked device rejects any movement command except for Home (Cmd 1), which homes the device and clears the park state. For firmware versions 7.14 and below the green LED fades in and out while the axis is parked. For firmware versions 7.15 and above the blue LED fades in and out while the axis is parked. Motor drivers remain enabled and hold current continues to be applied until the device is powered off. To restore a parked device, power it on and set Park State to 0.

Error Codes

This command may return the following error codes:

- 65

-

Park State Invalid

The requested park state is invalid or the device cannot park because it is in motion.

See also Error (Cmd 255)

Set Peripheral ID (Cmd 66)

Configures an axis for a particular peripheral

- Data

-

Peripheral ID

Any value defined in Zaber Support - Peripheral IDs or 0

- Reply Data

Peripheral ID

- Persistence

- Non-volatile

All Zaber peripheral ID numbers are specified at Zaber Support - Peripheral IDs. When Peripheral ID is set, the controller will configure the axis for the specified peripheral. Axis-scope data will be restored to its factory values.

- Restore all axis-scope settings to their default values.

- On products that support parking, unpark the axis.

- On calibrated peripherals without the autodetect feature, delete any calibration data saved for this axis.

- An invalid peripheral ID is provided.

- The axis is busy.

- An autodetect peripheral is plugged in and the provided ID does not match Pending Peripheral ID.

If the Peripheral ID is set to 0, the axis will enter unused mode.

Setting the peripheral ID to its existing value exercises all side effects listed above.

Introduced in 7.11

Example: Reading the peripheral ID

Read the ID of the peripheral configured on axis 1:

[1, 53, 66] → // Request to device 1, Return Setting, Set Peripheral ID

← [1, 66, 68332] // Response from device 1, Set Peripheral ID, 68332Set Index Distance (Cmd 79)

The distance between consecutive index positions

- Data

-

Distance

1 to 2,000,000,000

- Reply Data

Distance

- Persistence

- Non-volatile

The distance between positions reachable with the Move Index (Cmd 78) command.

For devices with a non-zero Cycle Distance, Index Distance should be set to less than Cycle Distance for Move Index (Cmd 78) commands to be accepted.

For linear devices, Index Distance should be less than or equal to Minimum Position and Maximum Position should be positive for Move Index (Cmd 78) commands to be accepted.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 79

-

Index Distance Invalid

The requested index distance is invalid.

See also Error (Cmd 255)

Set Cycle Distance (Cmd 80)

Sets the size of one full rotation of the device

- Data

-

Distance

0 to 2,000,000,000

- Reply Data

Distance

- Persistence

- Non-volatile

The distance the rotary device needs to move to complete one full rotation.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 80

-

Cycle Distance Invalid

The requested cycle distance is invalid.

See also Error (Cmd 255)

Set Filter Holder ID (Cmd 81)

Sets the ID of the currently installed filter holder

- Data

-

Holder ID

- 25

Filter holder model FH0625

- 32

Filter holder model FH0632

- Reply Data

Filter holder ID

- Persistence

- Non-volatile

Specifies the currently installed filter holder. Writing this setting also updates Index Distance to conform with the optic spacing of the filter holder.

Error Codes

This command may return the following error codes:

- 80

-

Cycle Distance Invalid

The requested cycle distance is invalid.

See also Error (Cmd 255)

Set Auto-Reply Disabled Mode (Cmd 101)

Specifies which commands the device replies to

- Data

-

Auto-reply disabled mode

- 0

Auto-reply enabled

- 1

Auto-reply disabled

- Reply Data

Auto-reply disabled mode

- Persistence

- Non-volatile

Error Codes

This command may return the following error codes:

- 101

-

Auto Reply Disabled Mode Invalid

The requested auto reply disabled mode is invalid.

See also Error (Cmd 255)

Set Message ID Mode (Cmd 102)

Specifies whether to enable message IDs

- Data

-

Message ID mode

- 0

Disabled

- 1

Enabled

- Reply Data

Message ID mode

- Persistence

- Non-volatile

This feature helps to associate commands with replies by including the same message ID in each. When Message ID Mode is enabled, byte 6 of the message (see Message Format) is interpreted as a message ID. When sending a command, the message ID can be set to any value between 0 and 255. When the device receives a command with a message ID, it will reply with a response containing the same message ID in byte 6.

For any messages sent spontaneously by the device, and not in response to a command, the message ID 0 is used. See Reply-Only Command Reference for a list of all reply-only commands.

Error Codes

This command may return the following error codes:

- 102

-

Message ID Mode Invalid

The requested message ID mode is invalid.

See also Error (Cmd 255)

Example: Communicating using message IDs

[0, 20, 10000, 1] → // Request to all devices, Move Absolute, Position 10000, Message ID 1

[0, 54, 0, 2] → // Request to all devices, Return Status, Ignored data, Message ID 2

← [1, 54, 99, 2] // Response from device 1, Return Status, Device busy, Message ID 2

← [1, 20, 10000, 1] // Response from device 1, Move Absolute, Position 10000, Message ID 1Example: Encoding binary commands with message IDs

Various commands and their byte encoding according to the Binary message format with message IDs are shown below.

| Command Description | Device | Command | Data (LSB → MSB) | Message ID | ||

|---|---|---|---|---|---|---|

| Request to all devices, Home (Cmd 1), ID 2 | 0 | 1 | 0 | 0 | 0 | 2 |

| Request to device 1, Move Absolute (Cmd 20) to position 257, ID 5 | 1 | 20 | 1 | 1 | 0 | 5 |

| Request to device 2, Move Absolute (Cmd 21) a distance of -1, ID 1 | 2 | 21 | 255 | 255 | 255 | 1 |

Set Home Status (Cmd 103)

Sets whether the device has a position reference

- Data

-

Home status

- 0

Has no reference

- 1

Has valid reference

- Reply Data

Home status

- Persistence

- Volatile

This value indicates whether the device has a valid position reference. This value is set to 0 automatically on power-up or reset. This value is set to 1 automatically when the device is homed or when the Current Position setting is written. The recommended way to give the device a valid position reference is to send the Home (Cmd 1) command.

Error Codes

This command may return the following error codes:

- 103

-

Home Status Invalid

The requested home status is invalid.

See also Error (Cmd 255)

Set Auto-Home Disabled Mode (Cmd 105)

Specifies whether the device will home when the home sensor is triggered

- Data

-

Auto-home disabled mode

- 0

Auto-home enabled

- 1

Auto-home disabled

- Reply Data

Auto-home disabled mode

- Persistence

- Non-volatile

When this setting is set to 0, the device will home whenever the home sensor is triggered during any knob motion or movement command. When this setting is set to 1, the device will ignore the home sensor except when the Home (Cmd 1) command is explicitly sent. This allows rotational devices to move multiple revolutions without re-triggering the homing mechanism.

Error Codes

This command may return the following error codes:

- 105

-

Auto-Home Disabled Mode Invalid

The requested auto-home disabled mode is invalid.

See also Error (Cmd 255)

Set Minimum Position (Cmd 106)

Sets the minimum position the device can move to

- Data

-

Position

-1,000,000,000 to 1,000,000,000

- Reply Data

Position

- Persistence

- Non-volatile

Sets the minimum position the device can move to. The range of travel (Minimum Position to Maximum Position) is different for each product.

Error Codes

This command may return the following error codes:

- 106

-

Minimum Position Invalid

The requested minimum position is out of range.

See also Error (Cmd 255)

Set Knob Disabled Mode (Cmd 107)

Enables or disables manual control through the knob

- Data

-

Knob disabled mode

- 0

Knob enabled

- 1

Knob disabled

- Reply Data

Knob disabled mode

- Persistence

- Non-volatile

The knob is located on the body of the controller. It can be used to manually control the motion of the device without sending commands to the serial port. Turning the knob moves the device (see Knob Movement Mode). Pressing the knob stops the device. The device decelerates at the rate defined by Deceleration Only unless it is already stopping; if the device is already stopping, it stops instantly.

If this setting is set to 0, the knob can be used to move or stop the device. If this setting is set to 1, turning or pressing the knob is ignored.

Error Codes

This command may return the following error codes:

- 107

-

Knob Disabled Mode Invalid

The requested knob disabled mode is invalid.

See also Error (Cmd 255)

Set Knob Direction (Cmd 108)

Specifies the direction to rotate the knob to move the device in the positive direction

- Data

-

Knob direction

- 0

Clockwise

- 1

Counter-clockwise

- Reply Data

Knob direction

- Persistence

- Non-volatile

When this setting is set to 0, turning the knob clockwise moves the device in the positive direction. When this setting is set to 1, turning the knob clockwise moves the device in the negative direction.

Error Codes

This command may return the following error codes:

- 108

-

Knob Direction Invalid

The requested knob direction is invalid.

See also Error (Cmd 255)

Set Knob Movement Mode (Cmd 109)

Sets the mode of the manual control knob

- Data

-

Knob movement mode

- 0

Velocity Mode

- 1

Displacement Mode

- Reply Data

Knob movement mode

- Persistence

Non-volatile

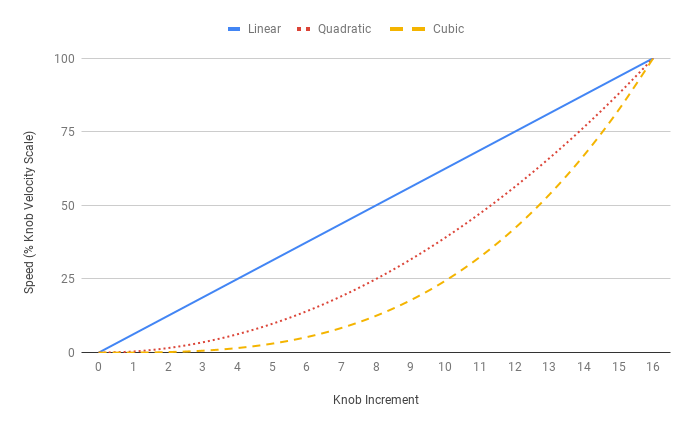

Specifies the mode of the manual control knob. In Velocity Mode, each knob increment increases the speed of the device. The maximum speed, Knob Velocity Scale, is reached after 16 increments and the magnitude of each speed increment is determined by the Knob Velocity Profile setting. In Displacement Mode, each knob increment moves the device a distance of Knob Jog Size.

To switch between these modes manually, press and hold the knob for one second.

Error Codes

This command may return the following error codes:

- 109

-

Knob Movement Mode Invalid

The requested knob movement mode is invalid.

See also Error (Cmd 255)

Set Knob Jog Size (Cmd 110)

Sets the distance moved for each knob increment

- Data

-

Distance

0 to 2,000,000,000

- Reply Data

Distance

- Persistence

- Non-volatile

Specifies how far the device moves with each knob increment when Knob Movement Mode is set to Displacement Mode.

If set to 0, each increment of the knob moves the device to the next index position. See Move Index (Cmd 78) for more details.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 110

-

Knob Jog Size Invalid

The requested knob jog size is invalid.

See also Error (Cmd 255)

Set Knob Velocity Scale (Cmd 111)

Sets the maximum speed that can be reached by the knob in Velocity Mode

- Data

-

Speed

1 to Microstep Resolution × 16,384 for stepper motor products

- Reply Data

Speed

- Persistence

- Non-volatile

Specifies the maximum speed at which the device will move as the knob is turned when Knob Movement Mode is set to Velocity Mode. When the device does not have a reference position, the speed achievable with the knob is also limited by Home Speed.

The Knob Velocity Profile setting determines the rate at which the speed increases as the knob is turned.

See the Physical Units section for information about unit conversions.

Error Codes

This command may return the following error codes:

- 111

-

Knob Velocity Scale Invalid

The requested maximum knob speed is out of range.

See also Error (Cmd 255)

Set Knob Velocity Profile (Cmd 112)

Specifies how the velocity changes as the knob is turned

- Data

-

Interpolation

- 1

- Linear

- 2

- Quadratic

- 3

- Cubic

- Reply Data

Interpolation

- Persistence

- Non-volatile

Specifies the relationship between knob increments and velocity when Knob Movement Mode is set to Velocity Mode. For instance, if set to 2 (Quadratic), the velocity will change quadratically with each increment of the knob.

The different profiles are shown below. No matter which profile is selected, Knob Velocity Scale will be reached in 16 increments.

Error Codes

This command may return the following error codes:

- 112

-

Knob Velocity Profile Invalid

The requested knob velocity profile is invalid.

See also Error (Cmd 255)

Set Acceleration Only (Cmd 113)

Sets the acceleration used when increasing speed

- Data

-

Acceleration

0 to 2,147,483,647

- Reply Data

Acceleration

- Persistence

- Non-volatile

Specifies the acceleration used for most motion trajectories. The deceleration is set separately using Deceleration Only. The Acceleration setting and Acceleration Only setting have the same value. If the Acceleration setting is changed, the Acceleration Only setting is also updated.

Error Codes

This command may return the following error codes:

- 113

-

Acceleration Only Invalid

The requested acceleration is out of range.

See also Error (Cmd 255)

Set Deceleration Only (Cmd 114)

Sets the deceleration used when decreasing speed

- Data

-

Deceleration

0 to 2,147,483,647

- Reply Data

Deceleration

- Persistence

- Non-volatile

Specifies the deceleration used for most motion trajectories. The acceleration is set separately using Acceleration Only. If the Acceleration setting is changed, the Deceleration Only setting is updated to the same value.

Error Codes

This command may return the following error codes:

- 114

-

Deceleration Only Invalid

The requested deceleration is out of range.

See also Error (Cmd 255)

Set Move Tracking Mode (Cmd 115)

Enables Move Tracking (Cmd 8) messages

- Data

-

Move tracking mode

- 0

Disabled

- 1

Enabled

- Reply Data

-

Move tracking mode

- Persistence

- Non-volatile

When Move Tracking Mode is set to 1 Move Tracking (Cmd 8) messages will be sent at the Move Tracking Period during most move commands. Similarly, for products with knobs, Manual Move Tracking (Cmd 10) messages will be sent during knob-initiated, constant-velocity moves, provided Manual Move Tracking Disabled Mode allows them as well.

Error Codes

This command may return the following error codes:

- 115

-

Move Tracking Mode Invalid

The requested move tracking mode is invalid.

See also Error (Cmd 255)

Example: Enabling move tracking messages

When Move Tracking Mode is set to 0, the device will not produce Move Tracking (Cmd 8) messages:

[0, 20, 100000] → // Request to all devices, Move Absolute, Position 100000

← [1, 20, 100000] // Response from device 1, Move Absolute, Position 100000

// (device at target position)Conversely, when Move Tracking Mode is set to 1, the device will produce Move Tracking (Cmd 8) messages like the following:

[0, 20, 100000] → // Request to all devices, Move Absolute, Position 100000

← [1, 115, 19892] // Response from device 1, Move Tracking, Position 19892

← [1, 115, 43320] // Response from device 1, Move Tracking, Position 43320

← [1, 115, 66767] // Response from device 1, Move Tracking, Position 66767

← [1, 115, 90195] // Response from device 1, Move Tracking, Position 90195

← [1, 20, 100000] // Response from device 1, Move Absolute, Position 100000

// (device at target position)Set Manual Move Tracking Disabled Mode (Cmd 116)

Disables messages resulting from knob-related actions

- Data

-

Manual move tracking disabled mode

- 0

Manual move tracking enabled

- 1

Manual move tracking disabled

- Reply Data

-

Manual move tracking disabled mode

- Persistence

- Non-volatile

When this setting is set to 1, the device will not produce messages due to knob-related actions. When it is set to 0, the device will produce the following messages:

- Home (Cmd 1) if the device reaches a limit sensor during a knob-initiated move and, as a result, performs the homing algorithm

- Manual Move Tracking (Cmd 10) at a rate set by Move Tracking Period while performing knob-initiated, constant-velocity moves

- Manual Move (Cmd 11) when knob-initiated, displacement moves finish

- Stop (Cmd 23) when the axis stops because of a knob press

- Set Knob Movement Mode (Cmd 109) when the knob mode is switched by pressing and holding the knob

Error Codes

This command may return the following error codes:

- 116

-

Manual Move Tracking Disabled Mode Invalid

The requested manual move tracking disabled mode is invalid.

See also Error (Cmd 255)

Example: Enabling manual move tracking messages

When Manual Move Tracking Disabled Mode is set to 0, the device will send messages like the following when using the knob in velocity mode:

// Knob in Velocity Mode

// Knob turned

← [1, 116, 19892] // Response from device 1, Manual Move Tracking, Position 19892

← [1, 116, 43320] // Response from device 1, Manual Move Tracking, Position 43320

// Knob pressed

← [1, 23, 63455] // Response from device 1, Stop, Position 63455 (device stopped)However, when Manual Move Tracking Disabled Mode is set to 1, using the knob in velocity mode will not produce messages:

// Knob in Velocity Mode

// Knob turned

// Knob pressed

// Deceleration time passed, device stoppedSet Move Tracking Period (Cmd 117)

Sets the time interval between Move Tracking (Cmd 8) or Manual Move Tracking (Cmd 10) messages

- Data

-

Move tracking period (ms)

10 to 65,535

- Reply Data

Move tracking period (ms)

- Persistence

- Non-volatile

The time between consecutive Move Tracking (Cmd 8) messages and, for products with a knob, Manual Move Tracking (Cmd 10) messages.

Error Codes

This command may return the following error codes:

- 117

-

Move Tracking Period Invalid

The requested move tracking period is invalid.

See also Error (Cmd 255)

Set Closed-Loop Mode (Cmd 118)

Sets the closed-loop operating mode

- Data

-

Closed-loop mode

- 0

-

Disabled

- 3

-

Position correction

- 5

-

Displacement recovery

- Reply Data

Closed-loop mode

- Persistence

Non-volatile

In closed-loop mode, the encoder-measured position is compared to the target position, and the difference is used to adjust the motion trajectory by:

- running a position control loop to improve accuracy,

- handling stalls, and

- detecting unexpected displacements when the axis is not moving.

When Closed-Loop Mode is set to 0 (disabled), the position read from the encoder will not be used to control the position of the axis. Slips, stalls, and displacements will only be detected when this setting is 3 (position correction) or 5 (displacement recovery).

A stepper motor can occasionally slip (when the rotating electric field cannot produce enough torque to drive the load, so four steps of the stepper motor are skipped). On stepper motor products with a motor encoder, when an axis slips with closed-loop mode enabled:

- Current Position is shifted by four full steps to better reflect the encoder position,

- a Slip Tracking (Cmd 12) reply is sent, and

- the blue LED turns on for 250 ms.

A stall occurs after a moving axis fails to keep up with the motion trajectory despite the motor applying maximum drive effort for a duration of Stall Timeout. A displacement occurs after a stationary axis is forced out of position for a duration of Stall Timeout. The behaviour after each of these events occurs is summarized in Table 1.

| Position Correction (3) | Displacement Recovery (5) | |

|---|---|---|

| Stall |

|

|

| Displacement |

|

|

Error Codes

This command may return the following error codes:

- 118

-

Closed-Loop Mode Invalid

The requested closed-loop mode is invalid

See also Error (Cmd 255)

Set Slip Tracking Period (Cmd 119)

Sets the time interval between Slip Tracking (Cmd 12) or Unexpected Position (Cmd 13) messages

- Data

-

Slip tracking period (ms)

0 or 10 to 65,535

A value of 0 disables slip tracking messages.

- Reply Data

Slip tracking period (ms)

- Persistence

- Non-volatile

The time between consecutive Slip Tracking (Cmd 12) or Unexpected Position (Cmd 13) messages that are sent while an axis is displacing or has slipped. See Closed-Loop Mode for a description of the Slip Tracking (Cmd 12) and Unexpected Position (Cmd 13) reply behaviour while an axis is displacing.

Set Stall Timeout (Cmd 120)