5 Things to Think About When Choosing a Linear Stage

By Mike McDonald, Applications Engineering Team

Published on Feb. 17, 2022

What is a linear stage?

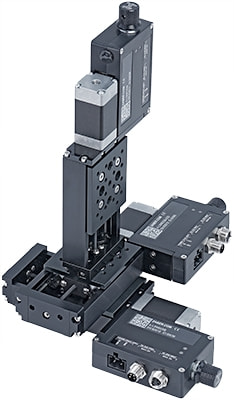

Many applications require some kind of automated movement. A linear stage is an instrument that controls motion in a linear direction, and includes bearings that support forces transverse to the direction of motion; in other words, it can carry a load. They may also be called linear translation stages, or linear slides. They can be used in single-axis systems, or more than one can be combined together to create multi-axis cartesian robots.

There are a wide variety of types of linear stages, using different types of controls, motors, bearings, and drive components. This allows users to find a good fit for their application, but it takes some consideration of what the requirements are and some understanding of the options available. This article describes 5 things you should consider when making this selection, and will hopefully help direct your search for the perfect solution.

1: Minimum Requirements

The minimum requirements of a system are often the easiest to describe, but ensuring you cover all of them will mean that you don’t forget any. These include things like the minimum stroke of the travel you need, restrictions to the size (length, as well as height or width) of the stage that you can incorporate, and the weight of the mass you will need to move (and where the center of that mass is). Even considering the number of axes the system will need is an important thing to keep in mind from the beginning.

The travel range should be something that is easy to sort various solutions on to find the right fit, but remember not to eliminate options that exceed your minimum travel requirement as long as it also fits the size requirement. For the size requirement, reviewing dimensioned drawings is the easiest way to compare different series. If you are designing your system using 3D design software, make sure a 3D model of the option is provided in a compatible format. On the weight and orientation of your moving mass, there are several specifications that will be relevant. There should be a rating for the centered load that the model can handle, as well as a limit to the amount of moment, also called moment load. If the stage will be lifting the load, the thrust limit will be more applicable.

Zaber aims to offer a variety of linear stage models with different bearing types to help fulfill a range of different requirements, from the LSA stepper motor linear stage with an extremely compact size to the X-LRT-C long travel motorized linear stage with a 500kg load capacity.

2: Performance Characteristics

Amongst the solutions that meet minimum requirements, next consider which one will offer the better performance in the areas that matter most for the application. There are many categories that may matter here, and selecting which aspects you need to optimize for will help to narrow down your options. It’s also important to understand how the different specifications of a model relate to the performance you are trying to achieve.

For example, Zaber’s devices are designed with high precision and accuracy in mind, and they offer fine resolution to make the most of these. A common question though is the value of fine resolution when the accuracy specification is an order of magnitude or two larger; understanding that the accuracy is a rating over full travel, and that over shorter distances accuracy will be much better helps to explain this. Another example is comparing whether the application really needs accuracy (comparing different points in travel), or whether repeatability (returning to the same position precisely) is more critical. The X-LDA-AE precision linear motor stage is an example of an extremely high accuracy and precision linear stage.

Another common trait to optimize for is speed. Many automation applications benefit from completing a task as quickly as possible. For these cases, keep in mind that acceleration may be a bigger factor for smaller moves. Stepper motor driven linear stages have a trade-off between thrust and speed, so look at the curve and where your typical move distance falls on it, as acceleration is directly related to thrust. The LC40B series of belt-driven motorized positioning stages can reach very high speeds with good thrust and acceleration, while also offering solutions with up to 3500mm travel.

3: Control

With the right mechanical solution selected, the next consideration is how it will fit in with the rest of your application. Usually a motion control system is only one piece of the puzzle, with other sensors, instruments, and components needing to work together. This will mean selecting a controller and driver that offers compatibility.

One important aspect is software compatibility. For example, many industrial automation processes will be controlled by a Programmable Logic Controller, so ensure that the right communication ports are supported on it (such as the Ethernet port on the Zaber X-MCC motion controller). For laboratory automation, it’s more likely that computer control is more useful, in which case look for a RS-232 serial or USB connection. With computer control, there’s also the choice of writing your own software (in which case you’d want to ensure there are programming libraries and a thorough API for the controller), or whether you’d use the controllers software for basic controls. Zaber offers the complete Zaber Launcher solution, along with programming libraries for Python, C#, C++, JavaScript, MATLAB, LabVIEW, and more.

Different controllers also support different motion modes. For example, for multi-axis systems a multi-axis controller is required if you want to finely synchronize the motion (see our article on Interpolated Multi-Axis Motion). For industrial requirements, an E-Stop function may be a firm requirement. For simpler positioning modes, a basic trapezoidal speed trajectory system may make control easier. For systems that need to do a raster scan motion, you can consider whether the scan will be continuous with a digital output offering synchronization with instruments throughout the motion, or if it should stop at each point in the scan to capture data (see our article on Image Stitching for an example).

4: Ease of Use

An often overlooked consideration is how much time investment will be required in implementing the motion control solution. It’s easier to evaluate performance specifications, but often harder to get a sense of what will be needed to deploy a system. These hidden costs can come in a number of areas, including integrating parts from different vendors and understanding their intercompatibility, reading manuals, setting tuning parameters, testing configurations for performance, and writing software.

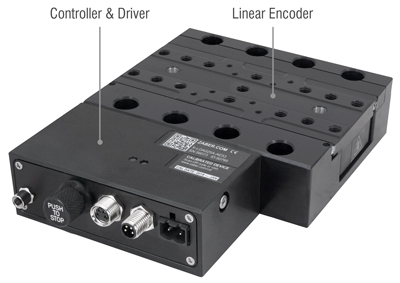

Your level of comfort with motion control will be a factor here; if you have past experience with this technology and specific components, it may help to accelerate this deployment time. With improvements in technology over the years though, more and more users are aiming to implement automation into their systems, and they may not have the time to devote to becoming an expert. An attribute to look for in this case is the level of integration of the system. If a system includes a controller, driver, motor, sensors, and mechanics all from the same vendor, it will ensure that there’s much less set-up time and that the end solution has been tested by the vendor to meet a certain level of performance.

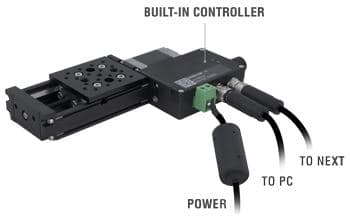

Zaber offers this type of fully-integrated motion control solution, including options with the drive and controls built on to the mechanics, so that all that’s required is connecting power and a USB connection. The Zaber X-LSM-E miniature linear translation stage is a popular fully-integrated solution in a compact package. A new user can get it connected and running in a matter of minutes.

5: Price and Costs

While the first four considerations have focused mainly on the solution and its performance, there trade-off will typically be the cost of the system. Different technologies have different costs, so it’s natural for linear stages to have a higher price as they get to a higher level of performance.

As mentioned in the previous section though, the time cost of implementation should also be considered when evaluating solutions. Assembling the lowest cost set of parts from different vendors may end up costing more in set-up and troubleshooting compared to a more expensive integrated solution. Another related cost is the delay in receiving parts due to the lead time; for example if you are using the system to prototype a solution, a delay of weeks or months may make an otherwise suitable solution useless. Zaber aims to offer 1-5 days lead times on devices to help support these kinds of cases. This can come at the cost of increased prices though, as it means that the vendor will need to carry more inventory to ensure stock levels.

Another hidden cost that can be easy to overlook is maintenance, support, and repair. Different bearing and drive technologies may have different lifetime expectations that also vary depending on loading and usage. If you opt for a lower up-front cost, it may mean needing to replace or refurbish the system earlier than you expect, and having to deal with a potential down-time while that happens. While it can be difficult to assess in the sourcing process, look for companies that offer helpful support, as they are likely also the ones who will work to support you quickly if these issues do arise.

Summary

These points have just covered the tip of the iceberg in terms of things you may need to consider. A key take-away is to try to define for yourself what the most important requirements and criteria are for your application, and to focus on those things. If you’re new to sourcing this kind of equipment, take advantage of the vendor’s applications team to ask questions and get advice. They should be helpful in matching up the available performance of different linear stage options with the needs of a variety of applications. Contact us to speak with one of Zaber's knowledgeable applications specialists.